Table of Contents

- Substrate Thickness and Material

- Coating Type and Adhesion

- Coating Structure

- Coating Types and Brands

- Packaging and Transportation Methods

- Processing Techniques and Special Requirements

- Why Choose Us?

Color-coated steel, as a metal material with an organic coating, is widely used in industries such as construction, home appliances, and transportation due to its excellent corrosion resistance, rich color options, attractive surface finish, and good processing adaptability.

In the construction sector, it is commonly found in roofing, wall cladding, and door/window systems for industrial and civil structures like steel-framed factories, airports, warehouses, commercial complexes, and cold storage facilities.

So, what key factors influence the final price of color-coated steel? This article systematically examines multiple dimensions, including substrate, coating, paint brand, and packaging methods.

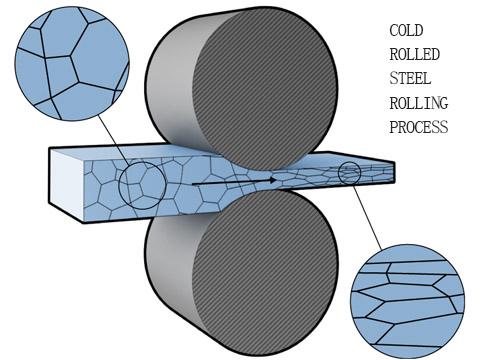

Substrate Thickness and Material

Substrate thickness significantly impacts the price per unit area. Generally, thinner steel sheets cover larger areas per ton, but this requires increased paint consumption and processing time during coating.

Consequently, thinner specifications like 0.13–0.16mm often command higher unit prices, while medium-thickness ranges (0.3mm–0.7mm) exhibit relatively stable pricing fluctuations.

Additionally, beyond standard cold-rolled steel coils, substrate materials include galvanized steel coils (GI), aluzinc steel coils (AZ), and ZAM steel, each with distinct material costs. The price hierarchy is: standard cold-rolled steel < galvanized steel coils (GI) < aluzinc steel coils (AZ) < ZAM steel.

Coating Type and Adhesion

The coating is the core factor determining the corrosion resistance of color-coated steel. Common zinc coatings exhibit significant price differences based on weight per unit area (e.g., 30g/㎡, 275g/㎡).

For standard environments, cost-effective 30g/㎡ galvanized sheets are suitable. In high-humidity, coastal, or high-temperature regions, aluminum-zinc coated steel (e.g., 55% aluminum-zinc alloy) is recommended due to its superior corrosion resistance, though at a higher cost.

Additionally, protective film coating for specialized applications incurs extra expenses.

Coating Structure

Color-coated sheets are categorized as single-sided or double-sided coated.

Single-sided coating typically features a front paint film thickness of approximately 10–30μm and a back thickness of about 5–10μm, suitable for internal dry environments.

while double-sided coated products achieve 11–30μm on both sides, offering more balanced overall protection at a relatively higher price.

Users should select based on actual application locations and environmental corrosion conditions. For instance, single-sided coating may suffice for indoor settings with low aesthetic demands and dry environments, while double-sided coating is preferable for outdoor applications or environments requiring high corrosion resistance.

Coating Types and Brands

The coating system is critical to the durability and appearance of color-coated steel sheets. Common types include:

- PE (Polyester): Economical, suitable for most standard environments;

- SMP (Silicone-Modified Polyester): Superior weather resistance compared to PE, suitable for moderately corrosive environments;

- HDP (High Durability Polyester): Significantly enhanced UV resistance and chalking resistance, offering extended service life;

- PVDF (Polyvinylidene Fluoride): Exceptional gloss retention, color stability, and chemical resistance, primarily used in high-end construction.

Additionally, performance and pricing vary across different coating brands (e.g., AkzoNobel, Nippon Paint, Berg).

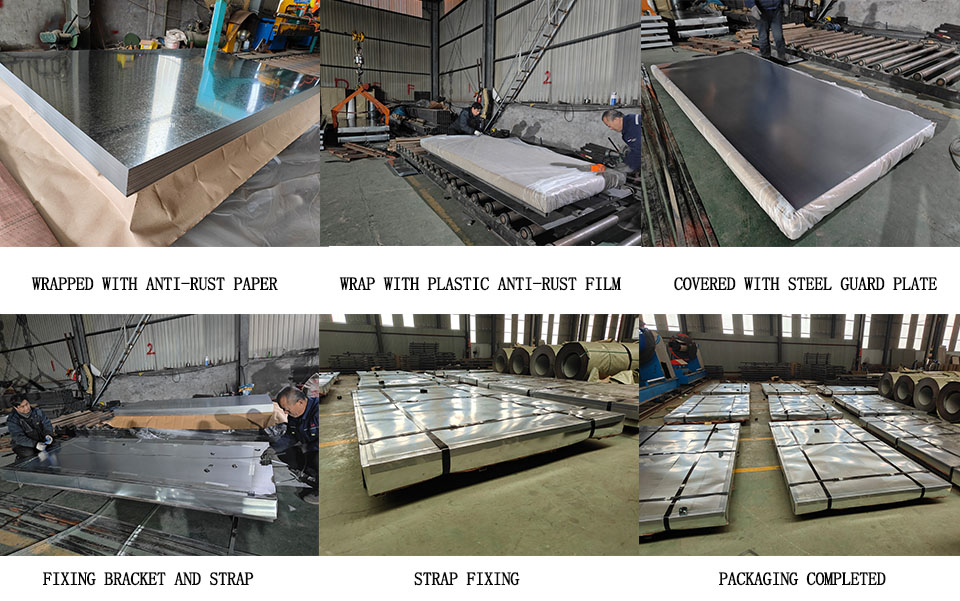

Packaging and Transportation Methods

The packaging method for color-coated sheets directly impacts product protection during transit and the final quotation:

- Basic Packaging: Only wrapped in waterproof kraft paper, suitable for short-distance transport with the lowest cost;

- Standard Export Packaging: Reinforced with galvanized iron sheets and steel wire strapping for shock and moisture resistance, ideal for ocean shipping and long-distance container transport;

- Special Vertical Packaging: Coils stored upright on wooden pallets to minimize crushing deformation, commonly used for premium clients or precision applications with higher packaging costs.

Wanzhi Steel Packaging

Processing Techniques and Special Requirements

During processing, different techniques also impact the price of color-coated steel:

- Complex processes like high-precision stamping, bending, or roll forming increase processing costs, thereby raising the final price.

- Custom requirements such as specific colors, dimensions, shapes, or functionalities like antibacterial, antistatic, or self-cleaning properties will also elevate the cost.

Beyond these factors, market fluctuations in raw material prices (e.g., zinc ingots, coating resins), order volume, production techniques (e.g., surface printing, embossing), and delivery lead times also significantly impact final pricing. Users are advised to select the most suitable product combination based on project requirements, considering service life, environmental conditions, and budget constraints.

Why Choose Us?

- With over 17 years of production experience and over 14 years of export experience, we export to over 100 countries and enjoy a global reputation.

- Our comprehensive production line and supply chain, including eight production lines for GI steel, GL steel, ZAM steel, color-coated steel, and printed steel, ensures high efficiency and sufficient production capacity.

- We have our own testing center with a rigorous testing process, encompassing specifications, performance, and other aspects, and support third-party testing.

- We hold numerous certifications, including ISO 9001, ISO 14001, ISO 45001, and are recognized as a trusted supplier and an enterprise with high integrity.

What Color-Coated Steel Can We Provide

Our color-coated steel offering is not limited to the following. We offer a wide range of colors, types, and functions:

What steel prices do we offer

To facilitate our customers’ understanding of steel prices, we have developed a specialized price list. Product prices include: