Color Coated Metal Coils For Home Appliances

Wanzhi Steel is able to supply a variety of materials for home appliance color-coated metal coils with a full range of specifications and diverse surface types to meet the various needs of home appliance manufacturing.

Thickness: Steel substrate: 0.2 – 1.6mm; Aluminum substrate: 0.3 -2.3mm

Width: ≤ 1550mm

Substrate: Cold rolled steel,Galvanized steel,Galvalume steel,Aluminium, etc

Ensure product quality and transportation

Color-coated metal coils for home appliances are both functional and decorative. The substrates are cold-rolled steel, hot-dip galvanized steel, hot-dip galvalume steel, aluminum alloy, stainless steel, etc. They can generally be divided into pre-painted (roller-coated) metal coils and laminated (film-coated) metal coils.

Specifications

| Product name | Color Coated Metal Coils For Home Appliances |

| Thickness | Steel substrate: 0.2 – 1.5mm; Aluminum substrate: 0.3 -2.3mm; Stainless steel: 3-5mm |

| Width | ≤ 1500mm |

| Substrate | Cold rolled steel, Galvanized steel, Galvalume steel, Aluminium, etc |

| Surface Type | Matte, texture, frosted, wrinkled, etc. |

| Paint Type | PE, HDP, SMP, PVDF |

| Coil Weight | ≤ 5.5 tons |

| Material | S420GD, DX51D, SPCC, SPGC, Q235, etc. |

| Processing Service | Cutting, slitting, embossing, etc. |

| MOQ | 10 Tons |

| Packaging | Standard export package or as per your requirements |

Production Video

Features

- Diverse materials and strong corrosion resistance.

- Excellent processing performance.

- Rich colors and strong decorativeness.

- Special coatings are highly functional (antibacterial, self-cleaning).

Specific Uses

- Door panels, side panels, and liner of refrigerators.

- Box and control panel cover of washing machines.

- Shells of indoor and outdoor units of air conditioners.

- Shells and door panels of ovens/microwave ovens.

- Shells and inner cavities of dishwashers.

- Shells of small appliances such as bread machines, electric kettles, and stereos.

Color-Coated Metal Coil for Home Appliances Classification

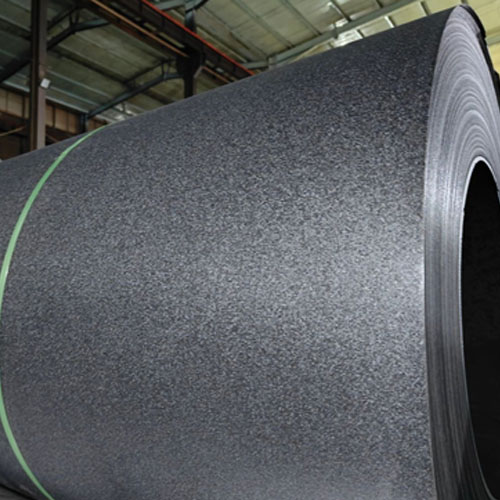

Pre-Painted Metal Coil

- Core Process: After cleaning and chemical conversion treatment, a liquid organic coating (such as PE or PVDF) is evenly applied to the surface of the substrate using a precisely controlled roller coater. Finally, the coating is baked and cured to ensure it adheres firmly to the metal surface.

- Substrates: cold-rolled steel, hot-dip galvanized steel, hot-dip galvanized steel, and electrogalvanized steel.

- Surface Coatings: Paint coatings such as PE, HDP, SMP, and PVDF (pre-painted).

- Excellent Decorative Effects: High gloss, matte, wrinkle-like, and metallic effects can be achieved.

- Strong Adhesion: The coating chemically bonds to the substrate, forming a single layer and resisting peeling during subsequent processing.

- Cost-Effectiveness: The mature production process and high efficiency make it the most cost-effective choice.

- Typical Applications: Cabinets and panels for most white goods, including refrigerators, washing machines, air conditioners, and microwave ovens.

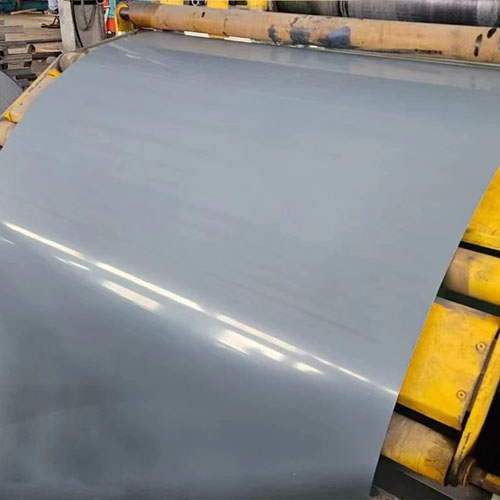

LAMINATED METAL COIL

- Core Process: Pre-printed and pre-textured plastic film (such as PET or PVC film) is laminated to a metal substrate using hot melt adhesive or adhesive under high temperature and pressure.

- Substrates: aluminum alloy, GI steel, GL steel, and stainless steel.

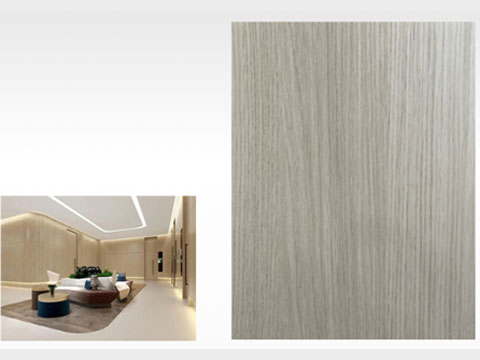

- Surface Textures: Glossy, matte, suede, frosted, orange peel, brushed, wood grain, stone grain, and leather grain.

- High Decorative Effect: Perfectly replicates complex patterns and three-dimensional textures such as real wood, fabric, leather, and stone grain.

- Performance Advantages: Provides excellent decorative and tactile properties, as well as superior wear and scratch resistance.

- Typical Applications: High-end, personalized home appliance panels.

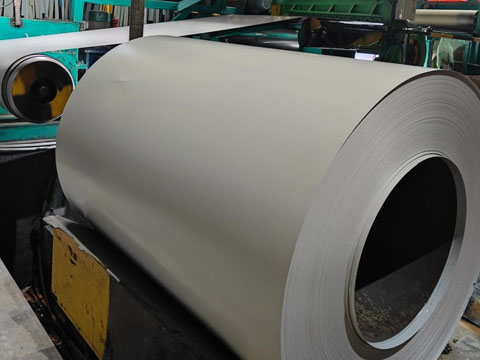

Classification by Substrate Material

- Cold-rolled substrate color-coated coils: smooth surface, good processing performance, low cost, and need to rely on coatings for corrosion protection.

- Hot-dip galvanized base color coated coil(PPGI Coil): strong corrosion resistance, suitable for humid environments (such as washing machines, dishwashers).

- Aluminum-zinc base color coated coil(PPGL Coil): more heat-resistant and corrosion-resistant, suitable for oven shells, air conditioner outdoor units, etc.

- Aluminum base color coated coil: lightweight, strong corrosion resistance, suitable for ultra-thin refrigerator doors, high-end electrical appliance panels.

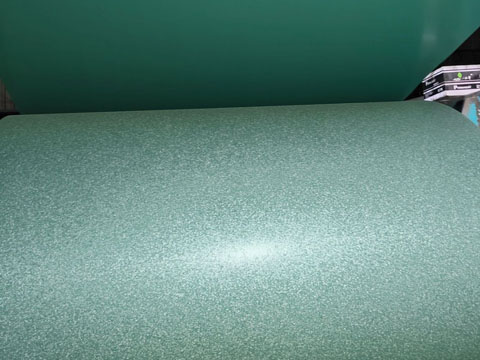

Classification by Surface Type

- High gloss/mirror color coated coil: used for high-end home appliance panels (such as refrigerator doors, air conditioner panels) to improve aesthetics.

- Matte/frosted color coated coil: anti-fingerprint, scratch-resistant, commonly used for washing machines, microwave ovens and other frequently contacted parts.

- Patterned color coated coil: the surface has a three-dimensional texture (such as wood grain, stone grain), used for decorative home appliance panels.

- Self-cleaning coating: the coating has hydrophobic or photocatalytic function to reduce stain adhesion (such as range hood shell).

- Antibacterial coating: adding antibacterial agents such as silver ions, suitable for parts with high hygiene requirements such as refrigerator liner and water dispenser.

How to Choose Color Coated Coil for Home Appliances?

When choosing color-coated steel sheets for home appliances, it is necessary to comprehensively consider the substrate, coating performance, surface effect, cost and specific application scenarios.The following are specific suggestions given by Wanzhi Steel:

- Corrosion resistance: It is recommended to choose galvanized substrate + SMP/PVDF coating in humid environments (such as washing machines).

- Aesthetics: High-gloss, textured, wrinkled, or patterned color-coated coils are suitable for visible parts (such as refrigerator doors).

- Functionality: High-temperature parts (oven) require heat-resistant coatings, and food contact areas (refrigerator liner) require antibacterial coatings.

| Home appliance type | Recommended color-coated coil types | Common colors |

| Refrigerator door panel | GI substrate + HDP coating | Pearl white, metallic gray |

| Air conditioner outdoor unit | AZ substrate + PVDF coating | Bright white, space gray |

| Washing machine panel | GI substrate + PE coating (matte) | Matte white, titanium |

| Oven liner | Aluminum substrate + SMP coating | Black, dark gray |

| Rancho hood shell | GI substrate + PVDF coating | Bright silver, black titanium |

| Water dispenser tank | Galvanized sheet + antibacterial coating | White, light blue |

Common Colors of Color-coated Coils for Home Appliances

- Pure white (RAL 9016/9010): most commonly used, suitable for popular home appliances such as refrigerators and washing machines.

- Light gray (RAL 7001/7035): modern and simple style, used for air conditioners, ovens, etc.

- Dark gray/metal gray (RAL 7016): industrial style design, commonly seen in embedded home appliances.

- Classic black (RAL 9005): high-end home appliances (such as steam ovens, dishwashers), matte treatment to prevent fingerprints.

- Bright silver (RAL 9006): Highly reflective texture, suitable for small appliances (such as electric kettles).

- Sky blue (RAL 5012) and deep space blue (RAL 5003) are used for refrigerators and water dispensers with youthful designs.

- Wine red (RAL 3005) and cherry blossom pink (RAL 3014) are targeted at the female market or children’s appliances.

Market Preferences

- The Asian market prefers white and champagne gold.

- The European market prefers dark gray and black.

- Colorful personalized designs are popular in North America.

Why Choose Us?

Wanzhi Steel has 3 color-coated steel production lines, and the production capacity of home appliance color-coated plates is 80,000 tons. The factory also has slitting, cutting, embossing and other equipment, which can provide a variety of processing services. Various specifications and rich colors can meet your various needs. If you have any needs, please feel free to contact us.

Our Color-coated Metal Coil Products For Home Appliances Include: