PPGI is a type of color-coated steel, the full name is Pre-Painted Galvanized Iron, it can also be called color-coated galvanized steel.

Table of Contents

- How is PPGI Produced?

- Performance Characteristics of PPGI

- Application of PPGI

- PPGI Coating Types

- What are The Types of PPGI Products?

- PPGI vs PPGL

- Wanzhi Steel-Famous PPGI Manufacturer in China

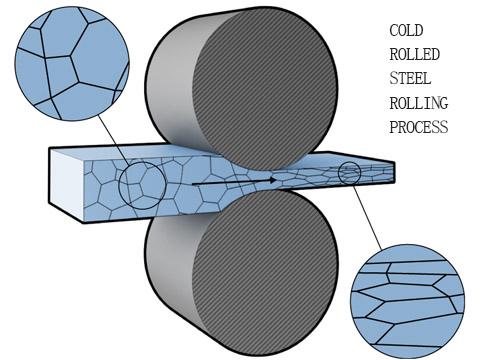

How is PPGI Produced?

1. Raw material preparation

- Select hot-rolled steel sheets or cold-rolled steel sheets with smooth surface and no defects as substrates.

- The substrate is treated with hot-dip galvanizing or electro-galvanizing to form a uniform and continuous zinc layer on the surface of the steel sheet.

- According to the requirements of PPGI products, galvanized steel sheets of different materials, specifications and grades are selected as raw materials.

2. Pretreatment

Before pretreatment, the galvanized steel coils need to be unrolled so that they can enter the production line continuously and at a uniform speed. Then pretreatment is carried out, which includes:

- Alkaline washing and degreasing: remove oil and impurities on the surface of the steel coil to ensure the surface is clean.

- Cleaning: Clean the degreased steel plate with clean water to ensure that no residual liquid remains.

- Passivation: Improve the corrosion resistance of the steel plate and its adhesion to the upper paint film.

- Drying: Prepare for the subsequent coating process.

3. Coating process

Coating is the core link of PPGI steel production. Roller coating technology is usually used, which is divided into three layers of coating: primer, topcoat and backcoat. The painting steps are as follows:

- Preliminary coating: Apply primer and back paint on both sides of the steel plate, and bake and cure.

- Fine coating: Apply topcoat on the basis of the initial coating, and select and customize the color according to customer requirements.

- Baking and curing: Use a continuous baking furnace to cure the coating by high-temperature baking to ensure uniform curing of the coating.

- Cooling: Rapid cooling through air cooling or water cooling system to stabilize the coating performance.

- Post-processing: Surface treatments such as embossing, printing or lamination can be performed according to needs to increase decorative effects or functionality.

4. Quality inspection

- Appearance inspection: Check whether there are scratches, bubbles, foreign matter, uneven defects.

- Coating thickness measurement: Use a thickness gauge to detect the coating thickness to ensure customer requirements.

- Adhesion test: Test the coating adhesion by cross-cutting method or pull-off method.

- Corrosion resistance test: Evaluate corrosion resistance through salt spray test.

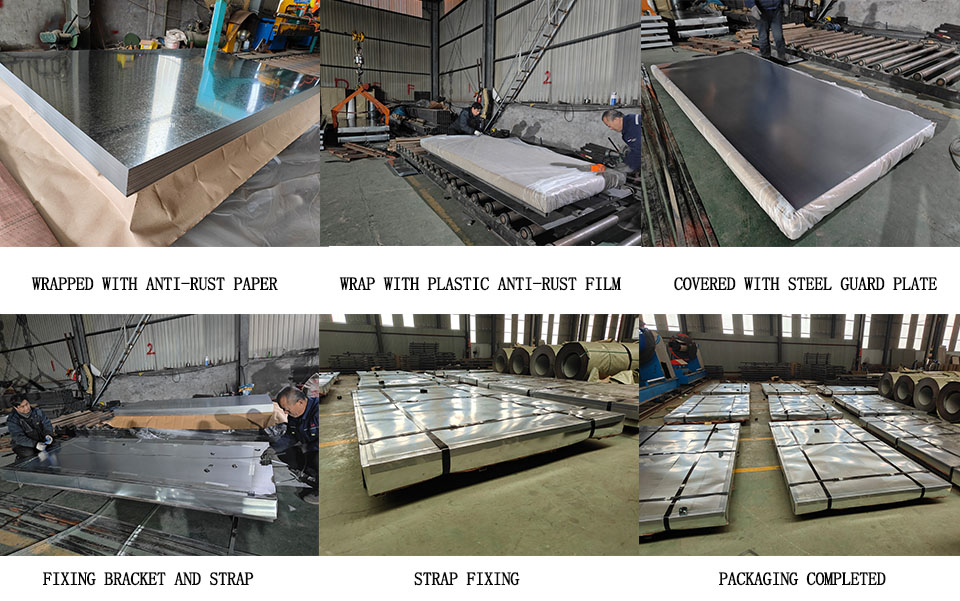

5. Reeling and packaging

- Reeling: Use a reeling machine to reel the painted steel sheet.

- Packaging: Use waterproof and scratch-resistant packaging materials to ensure that it is not damaged during transportation.

Performance Characteristics of PPGI

Excellent corrosion resistance

- Galvanized layer protection: The dense zinc layer on the surface of galvanized steel, the substrate of PPGI, has strong corrosion resistance.

- Coating protection: The organic coating on the surface of PPGI (such as PVDF or HDP) further isolates the steel plate from the external environment and enhances corrosion resistance.

Excellent decorativeness

- Rich color selection: PPGI can provide a variety of colors and surface effects (such as gloss, matte, frosted, wrinkled, etc.) to meet different design needs.

- Beautiful surface texture: Through printing, embossing and other processes, PPGI can present decorative effects such as wood grain, stone grain, brick grain, and pattern.

Good processing performance

- Easy to form: PPGI has good ductility and toughness, and is suitable for processing processes such as stamping, bending, and bending.

- Weldability: Under appropriate process conditions, PPGI can be welded to meet the processing needs of complex structures.

- Cutting: PPGI can be cut using conventional cutting tools, which is convenient for on-site construction.

Excellent weather resistance

- UV resistance: High-quality coatings (such as PVDF) can effectively resist UV radiation and prevent coating aging and fading.

- Temperature difference resistance: PPGI can maintain stable performance in high and low temperature environments and is suitable for various climate conditions.

Economical

- Long service life: PPGI’s corrosion resistance and weather resistance make it have a long service life and reduce maintenance and replacement costs.

- Low overall cost: Although PPGI has a higher initial cost, it has a long service life, reduced replacement frequency, and reduced overall cost.

Other features

- Strength and toughness: PPGI retains the strength and toughness of galvanized steel.

- Recyclable: PPGI’s materials can be recycled and reused to reduce resource waste.

- Heat and sound insulation: PPGI can be combined with heat and sound insulation materials to form composite panels with good heat and sound insulation properties, such as metal sandwich panels.

Application of PPGI

- Construction: roofs, wall panels, partitions, ceilings, door and window frames

- Home appliance industry: the outer shell or internal components of home appliances.

- Automotive industry: body panels, chassis components, interior trims, etc.

- Furniture industry: the outer shell and internal components of wardrobes, cabinets, etc.

- Advertising industry: billboards, signboards, light boxes, etc.

- Transportation: interior decoration and structural parts of trains, subways and other transportation vehicles; commonly used in the manufacture of highway guardrails, containers, etc.

PPGI Coating Types

| Coating type | Features | Advantages | Disadvantages | Application areas |

| Polyester coating (PE) | Good weather resistance, chemical resistance and decorative properties, cost-effective. | 1. Rich colors and strong decorative effect 2. Low cost 3. Good processing performance | Average weather resistance, suitable for medium environment; poor wear resistance | Building roofs, wall panels, home appliance housings |

| Silicon modified polyester coating (SMP) | Weather resistance and durability are better than ordinary polyester coatings. | 1. Good UV resistance 2. Strong anti-powdering and fading performance 3. Long service life | The cost is higher than ordinary polyester coating; the decorative effect is slightly inferior to PVDF coating | Outdoor buildings, industrial plants, billboards |

| High weather resistant polyester coating (HDP) | Weather resistance and durability are better than ordinary polyester coatings, close to PVDF coating performance. | 1. Excellent weather resistance 2. Strong UV resistance 3. High cost performance | The cost is higher than ordinary polyester coating; the decorative effect is slightly inferior to PVDF coating | Outdoor buildings, transportation facilities, agricultural equipment |

| Fluorocarbon coating (PVDF) | High-end coating with excellent weather resistance, chemical resistance and self-cleaning properties. | 1. Super strong weather resistance, service life up to 20-30 years 2. Excellent UV resistance and anti-powdering performance 3. Good self-cleaning performance | Higher cost; relatively few color options | High-end building curtain walls, airports, stadiums |

Corrosion resistance and weather resistance of different coatings

| Coating topcoat type | Neutral salt spray resistance test time is not less than (h) |

| Polyester (PE) | 480 |

| Silicon-modified polyester (SMP) | 600 |

| High-durability polyester (HDP) | 720 |

| Polyvinylidene fluoride (PVDF) | 960 |

| Coating topcoat type | Ultraviolet accelerated aging test time is not less than (h) | |

| UVA-340 | UVB-313 | |

| Polyester (PE) | 600 | 400 |

| Silicon-modified polyester (SMP) | 720 | 480 |

| High-durability polyester (HDP) | 960 | 600 |

| Polyvinylidene fluoride (PVDF) | 1800 | 1000 |

Source: https://wanzhi-steel.com/ppgi-ppgl/ppgi-ppgl-specifications/

What are The Types of PPGI Products?

There are many types of finished products for sale of color-coated galvanized steel (PPGI). Wanzhi Steel supplies PPGI-related products including coils, plates, strips, corrugated steel, etc.

- PPGI Coil: It has good processing performance and can be processed into roof panels, roof tiles, internal and external wall panels, etc.

- PPGI Sheet: It is made by cutting coils and is commonly used for indoor partitions, building exterior/interior wall decoration, furniture, distribution boxes, switch cabinets, etc.

- PPGI Strip: It is made by longitudinally cutting coils and is used to manufacture automotive decorative strips, various hardware accessories, building sealing materials and other products.

- PPGI Corrugated Sheet: It is made by pressing coils or plates through pressing and forming equipment, and is a common material for roofs and walls.

PPGI vs PPGL

| Comparison Items | PPGI | PPGL |

| Appearance | It has good decorative properties and rich colors, including red, blue, black, white, gray, etc. | The appearance is similar to PPGI, and it also has a rich color selection. |

| Weight | Under the same coating thickness, PPGI is relatively heavy due to the large specific gravity of zinc. | The specific gravity of aluminum is less than that of zinc. When the coating thickness is the same, the aluminum-zinc coating of PPGL is lighter. For the same weight of coating materials, PPGL can cover about 3% more area than PPGI. |

| Corrosion Resistance | Relying on the zinc layer to provide protection, it has certain corrosion resistance in general environments, but in harsh environments such as high humidity and high salt, the substrate is easily affected after the zinc layer corrodes. | In the aluminum-zinc alloy coating, the zinc-rich part corrodes first, and the aluminum-rich part corrodes slowly, which can provide better corrosion resistance than PPGI, especially suitable for harsh outdoor environments such as coastal areas. |

| Service Life | Under normal conditions, the service life is long, but it will be shortened when affected by a corrosive environment. | Due to its excellent corrosion resistance, the service life of PPGL can reach about 3 times that of PPGI. |

| Application | It is suitable for building roofs and walls that do not require extremely high corrosion resistance, such as ordinary residential buildings, industrial plants, etc.; it is also widely used in automobile manufacturing and home appliance industries, such as automobile body parts, refrigerator air conditioner shells, etc.; it can also be used for some ordinary advertising signs, etc. | It is more suitable for occasions with high requirements for corrosion resistance and heat resistance, such as buildings in coastal areas and industrial facilities in high temperature environments; in building roofs and wall applications, it can better withstand bad weather; it is also commonly used in equipment with heat resistance requirements such as ovens, chimney pipes, etc. |

Both PPGI and PPGL are color-coated steel. When choosing which product to use in actual applications, you need to consider many aspects. You can refer to Wanzhi Steel’s advice on “How to Choose Color-Coated Steel“

Wanzhi Steel-Famous PPGI Manufacturer in China

If you have any questions about PPGI or would like to invest in PPGI, please feel free to contact us for details.