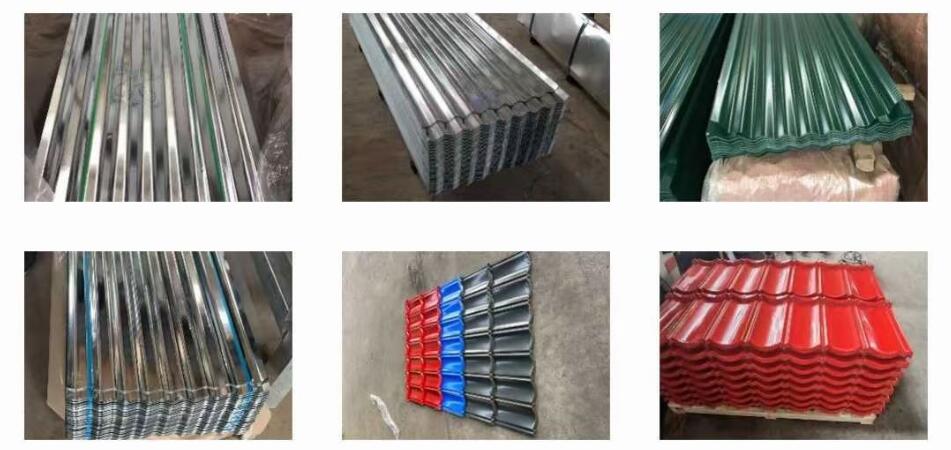

You can see corrugated steel sheets with rich colors and shapes everywhere in life, municipal engineering standing boards, colorful roofs of houses, garage doors, and walls of simple houses, the reason why they are so versatile is because they have lots of advantages. There are corrugated sheets for sale at WanZhi, as well as pattern-printed corrugated sheets. Prints and solid colors also can be made. You can also send us your patterns, and we support customization. Next, let’s learn more about corrugated steel sheets!

What is Corrugated Steel Sheets?

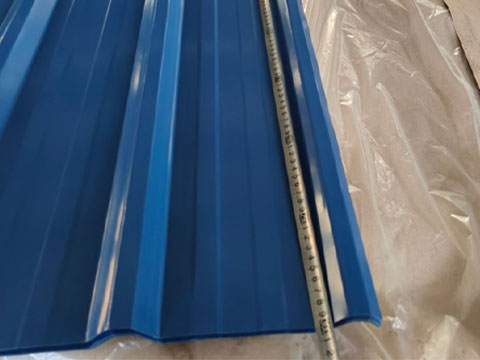

A corrugated sheet is called a corrugated sheet because it has flutes and grooves, it is also called a corrugated steel sheet and pressure plate. It is a lightweight metal material with a corrugated structure, made of thin sheets, reinforced by corrugations, which increase the strength and stiffness of the material, taken from steel, in fact, without these corrugations, the sheet would be weak and easily deformed.

Simply put, it is a certain size of steel (SS400, SS490, SS590, etc.) made through a series of steps such as corrugated moulding, and the production of some corrugated steel may also include hot-dip plating (900g/㎡ on both sides) . This step is usually carried out after moulding. The life span of corrugated sheet can be up to 50~100 years or more. It is not only light and strong but also earthquake, pressure and corrosion resistant. It is an ideal material to replace traditional wood and metal panels. It has a very good-looking appearance and can be made into a variety of styles.

Why Use Corrugated Steel Sheets?

Because corrugated steel sheets has many practical properties in addition to its good looks, it is firstly waterproof, which is particularly suitable in high humidity and rainy environments; secondly, sound and heat insulation, its material can effectively reduce noise and heat transfer, creating a comfortable living environment; and there are also fireproof properties, which can quickly slow down the spread of fire, which is much safer than buildings made of wood or other materials, and in the fireproof decorations there is an example of corrugated steel sheets. Finally, its structure can be designed and produced according to specific applications, so flexibility and diversity are high.

Is corrugated steel plate strong? How strong is it?

Yes, it is strong! Corrugated metal lasts longer than other materials, with an expected life of 40-70 years. No matter how you use it, even if there are extreme weather conditions, if the use of the environment is indoor, its service life will be further extended, that’s why it is said that durability is one of its biggest advantages.

What is corrugated steel sheet made of?

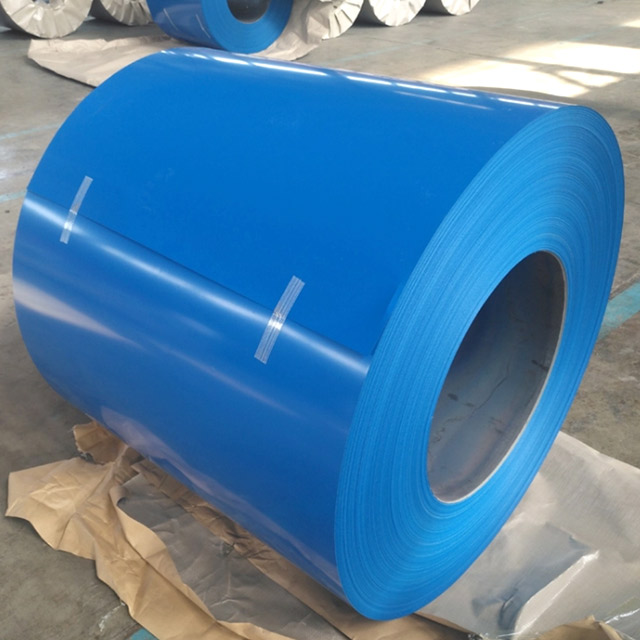

Corrugated steel is made from color coated sheets, galvanized sheets and other metal sheets. The fabrication process involves several steps, which are detailed below:

1.Material Preparation

Prepare the required steel or aluminium plates and cut them to the required size. The thickness of the sheet affects the strength of the final product; the greater the thickness, the greater the strength usually is, but the cost also increases.

2.Roll forming

The cut plate is put into the roll bending machine. Through repeated roll bending, the plate is pressed into a corrugated shape. This step is the key to making corrugated steel, it is necessary to pay attention to the number of rolls and roll shape of the roll bending machine is appropriate.

3.Coating spraying

If required, the corrugated sheet will be coated after moulding. Common coating materials include polyester, silicone polyester, polyurethane and so on. The coating needs to be even and firm to prevent it from rusting.

4.Edge trimming and punching

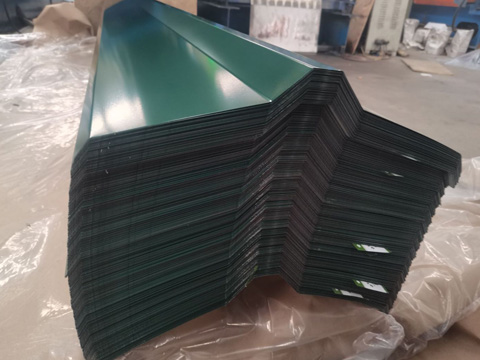

In order to specific size and shape requirements, the corrugated sheet is processed by edge trimming and punching using equipment, such as shearing machines and punching machines.

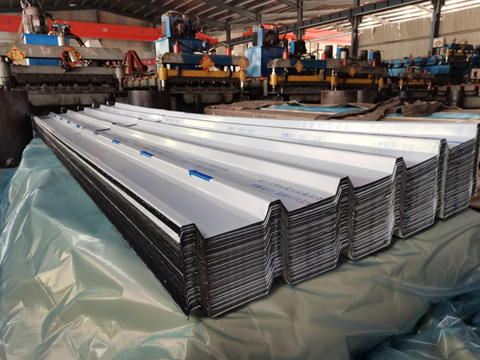

5.Finishing and packing

Finish the processed corrugated boards and box them for transport and storage.

The production process of corrugated steel requires strict compliance with operating procedures. Ensure that each step is done correctly for the quality of the final product. Meanwhile, pay attention to safety to avoid personnel injury or equipment damage.

What are the benefits of corrugated steel sheets?

As an important building material, corrugated board has many significant advantages that make it widely used in various fields. The following is a detailed description of the advantages of corrugated sheets:

1.Cushioning performance

Wave-shaped structure improves cushioning performance. In the field of packaging and transport, it can protect the goods and reduce the damage caused by collision and fall.

2.Lightweight and firm

Light weight and high strength. It makes the construction and installation more convenient and fast.

3.Sufficient raw materials& low cost

Wide range of raw material sources, such as paper, metal, etc., making it relatively low cost. High market competitiveness

4.Automated production

The production process is easy to automate, with high production efficiency. The automated way ensures the stability and consistency of quality.

5.Environmental protection

Recyclable, in line with environmental requirements. The production and use process will not cause serious pollution to the environment, in line with the concept of sustainable development.

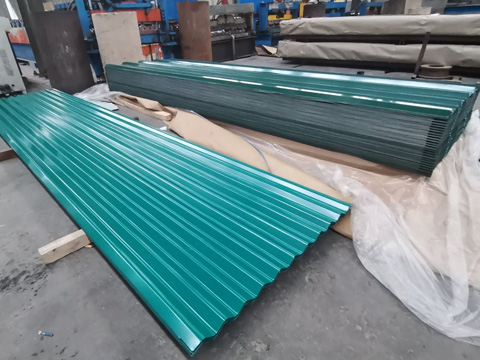

6.Strong decorative

Rich colors and diverse shapes can meet different architectural styles and decorative needs. Enhances the overall image of the building.

7.Good waterproof and anti-seismic properties

it is still well used in humid environment or earthquake-prone areas, providing certain guarantee for the safety and stability of the building.

8.Wide range of uses

In addition to the construction field, there are also many areas of packaging and transport. Its wide range of applications gives corrugated board a large demand and room for development in the market.

In summary, corrugated steel sheets have many advantages, making it widely used in various fields. With technological advances and process improvements, the performance and application range of corrugated board will be further enhanced!

What is corrugated steel sheets used for?

Corrugated board has a wide range of applications. It has unique structural characteristics and excellent performance. Specifically, the main application areas of corrugated sheets include:

1.Road sector

The application of the dangerous road: high fill section, high cold tundra area, near the sea area, temporary road, overpass, coal mine mining area, the material of the project cost is one-sixth lower than the concrete. For highway projects, corrugated steel cost savings of 10%-50%.

2.Agricultural

Farm Irrigation Inverted Siphon, Soakaway, Agricultural Savings Tanks, Farm Irrigation Inverted Siphon, Grain Storage Barns, Corrugated sheet stockrooms.

3.Sports equipment

Professional Fitness Equipment, Corrugated Plate Massager, Vertical foot spinning exercise gym equipment, Mountaineering boards, Sprinting equipment and so on. These equipments are sturdy, durable, which makes it easy for sports enthusiasts to carry out various outdoor activities.

4.Furniture industry

Background wall, Park chair back,business hall decoration, space modeling, its lightweight and sturdy characteristics make the furniture both practical and beautiful.

5.Transport

the production of items such as packing boxes, transport pallets, floor boards, etc., which have a protective role in the transport process.

6.Packaging industry

Various types of product packaging, food, medicine, textiles, tobacco, alcohol, light industry. In addition, its exquisite printing technology also occupies a place in the sales packaging.

7.Architecture

Covering of roofs and walls of building structures, and also making display racks, headboards, windows, billboards and other advertising display facilities.

Overall, corrugated steel sheet is a superior performer and an indispensable material in modern society. Whether for traffic, construction, transport or furniture and sports equipment manufacturing, corrugated board has won people’s favour with its outstanding performance.

Are corrugated sheets rust proof?

Yes, if there is a galvanizing step, it means that the surface of the sheet is coated with a zinc layer, which is a way to protect the sheet from erosion or can greatly extend the time it takes for the sheet to rust, provided that the zinc layer is not damaged; It can also be sprayed with anti-rust paint, so it is rust proof. However, if it is not galvanized and not sprayed with anti-rust paint, rust will gradually appear, and rusting is accelerated in salt-water coastal areas, or in industrial environments where there is acid rain and a high degree of humidity. Unpainted rust usually starts to appear in 5-10 years.

Are corrugated steel sheets waterproof?

Waterproof, since the corrugated steel can be used as building roofs, walls, firefighting equipment, of course it is waterproof, it waterproof performance is excellent, can block the penetration of rain, snow and moisture.

Is corrugated steel sheet expensive?

Cost-effective, corrugated sheets have been one of the most cost-effective materials for decades. Final prices will depend on your supplier, your location, and the area that you need covered.

Why are sheets corrugated?

To make it stronger. It is stiffer and less deformable than flat sheets and is not afraid of being subjected to impacts. Due to the increased stiffness and strength, the plates do not sag.

How to protect corrugated board?

The surface is galvanized or coated with anti-rust paint treatment to make the surface bright and wear-resistant, thus prolonging its life. Here are some protection methods:

1.Storage environment

dry and ventilated environment, away from water sources, humid areas and high temperature areas. Avoid prolonged exposure to sunlight

2.Storage environment humidity

In the process of storage and use, take moisture-proof measures, avoid direct contact with the ground, and regularly check the environmental humidity

3.Pressure coefficient

Avoid it being sandwiched between heavy objects to avoid extrusion and deformation. Reasonable placement, avoid heavy objects directly pressing on the corrugated board.

4.Reasonable placement

The corrugated sheets should be sorted and stacked according to specifications and uses, and the height of each pile shouldn’t be too high, so as not to collapse and cause deformation or damage to the corrugated steel sheets.

5.Maintenance inspections

Inspect regularly for damage, deformation or moisture. Once problems are found, take timely measures to repair or replace them.

In short, Protecting corrugated steel sheets requires a number of aspects, including the storage environment, protection against moisture and pressure, reasonable placement and regular maintenance and inspection. Only by doing a good job can we ensure the normal use of corrugated board and extend its service life.

Difference between corrugated and galvanized steel sheets?

| Type | material | structure | application | feature |

| Corrugated Steel Sheet | Galvanized steel, Color coated steel, Stainless steel, Aluminium… | Corrugated | Roofing, Soundproofing Panels, Fireproofing panels, Container (for shipping) | Corrosion-resistant, Beautiful, Impact-resistant… |

| GalvanizedSteel Sheet | Galvanised steel | Flatbed | Roofs, Facades, Appliance housings, Car frames… | High strength, Durability, Economic efficiency… |

How do I calculate the number of corrugated roof sheets?

To calculate the number of sheets, divide the total roof area (including overhangs and slopes) by the area covered by individual corrugated sheets, and the resulting number is the number currently required. To make sure it is enough, choose a number larger than the score to purchase.

Recommended reading: Corrugated steel plate weight calculation formula

Conclusion

Corrugated steel sheets are used in almost all areas, whereas concrete and ordinary steel sheets were used as building materials in the past! Above is the knowledge of corrugated steel sheets from the definition, use, material, characteristics, production, advantages, history, and calculation.

When you come across corrugated steel sheets again in the future, you will have a different feeling when you get to know them better. How else would it be so versatile? It will also continue to improve its performance and use, creating convenience for more users! If you are hesitating about the project to take the material, welcome to inquire, the free answer for customization, meanwhile welcome to visit the WanZhi factory, if you are interested in knowing more about the products at WanZhi, you can contact us at any time.