Antibacterial Color Coated Steel

Antibacterial color-coated steel is a functional color-coated steel with antibacterial effect.We use high-quality antibacterial agents, and the product has stable antibacterial performance and long service life.

Thickness: 0.2 – 1.5mm

Width: 600 – 1250mm

Substrate Type: Galvanized steel (GI), galvalume steel (GL), cold rolled steel

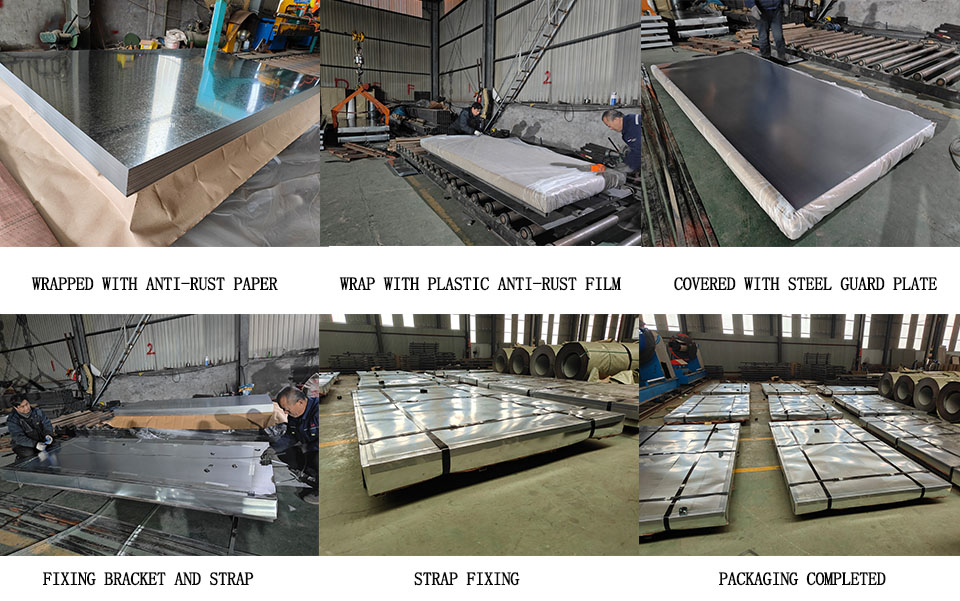

Ensure product quality and transportation

Antibacterial color-coated steel has the advantages of antibacterial, anti-mildew, anti-corrosion, waterproof, fireproof, and beautiful. It is widely used in medical, food, catering, scientific research, agricultural breeding and other fields. If you have any questions about antibacterial color-coated steel, please feel free to contact us.

Specifications of Antibacterial Color Coated Steel

| Product name | Antimicrobial Color Coated Steel |

| Thickness | 0.2 – 1.5mm |

| Width | 600 – 1250mm |

| Substrate Type | Galvanized steel (GI), galvalume steel (GL), cold rolled steel |

| Antimicrobial agent type | Silver ions, zinc ions, titanium dioxide (TiO₂) |

| Paint Type | PE, HDP, SMP, PVDF |

| Colors | According to RAL color card |

| Coil Weight | 3 – 6 tons or as your request |

| Coil inner and outer diameter | Inner diameter: 508-610mm, outer diameter: 800-1500mm |

| Standard | ISO 22196, JIS Z 2801, GB/T 21866 |

| Processing Service | Opening, striping, cutting, etc. |

| MOQ | 10 tons |

| Packaging | Horizontal or vertical packaging or as per your requirements |

How Color Steel Sheets Achieve Antibacterial Effects

There are two main ways to achieve the antibacterial effect of color-coated steel. One is to add antibacterial agents to the coating, and the other is to cover the surface with an antibacterial film (such as photocatalytic titanium dioxide coating).

Antibacterial Principle

Using sustained-release antibacterial technology, antibacterial factors are evenly dispersed throughout the topcoat layer. These antibacterial factors are slowly released with use, ensuring a long-lasting antibacterial effect.

Strong Bacterial Range

The inorganic antimicrobial agent (silver ion/zinc ion complex system) added to the special topcoat effectively kills a wide range of pathogens, including Escherichia coli, Staphylococcus aureus, and Pseudomonas aeruginosa. It also inhibits Klebsiella pneumoniae and Candida albicans.

Wanzhi Antibacterial Color Coated Steel Advantages

- The product has excellent antibacterial properties, and the inhibition rate of common bacteria is ≥99%.

- Using high-quality antibacterial agents, the antibacterial performance is stable.

- Strong corrosion resistance, double-layer protection formed by high-quality substrate and good coating.

- Good decorative effect, rich colors, high gloss and good flatness.

- Good processing performance, easy to cut, bend and weld.

- Easy to clean, low maintenance cost and long service life.

- High cost performance, low comprehensive cost and wide application range.

Application of Antibacterial Color Coated Steel

Antibacterial color-coated steel sheets are primarily used in the home appliance industry, hospitals, and the food industry.

- Home appliance: refrigerators/freezers, microwave ovens/ovens, dishwashers/disinfectors, smart toilet lids, water heaters/wall-mounted boilers, and maternal and infant appliances.

- Hospitals: operating room walls, ward partitions, medical device housings, antibacterial door panels, pharmaceutical cleanroom walls, equipment housings, etc.

- Food industry: cold storage panels, food processing workshop wall panels, work surfaces, etc.

Packaging

Why Choose Us?

- The company has passed ISO 9001:2015 certification and is a certified enterprise that values integrity, quality and contracts.

- With professional testing equipment and technicians, we will conduct strict testing on products to ensure product quality and support third-party testing.

- With many years of production and export experience, we have successfully served more than 1200+ projects.

Wanzhi Steel has 3 color-coated steel production lines, which can produce color-coated steel of various specifications, and has equipment such as longitudinal shearing, cutting, and profiling, which can provide a variety of processing services. If you have any color-coated steel needs, please feel free to contact us.