PPGL steel substrate aluminum-zinc steel contains 55% aluminum, 43.4% zinc and 1.6% trace elements.

PPGL steel has strong corrosion resistance and good decorative properties. It is a widely used building material, especially in roofs and walls. This article mainly introduces the production process, use, price and other information of PPGL steel.

Table of Contents

- What is PPGL material?

- Production process of ppgl steel

- PPGL steel uses

- Which is better, PPGL steel or PPGI steel?

- PPGL steel price

- What are the advantages of Wanzhi ppgl steel

- Conclusion

What is PPGL material?

ppgl full form

PPGL full form is “Pre-painted Galvalume”, which is a pre-coated 55% aluminum-zinc alloy steel plate.

PPGL steel specifications

- Width range (mm): 30-1250mm (±2 mm); this width includes PPGL steel strips and steel coils.

- Thickness range (mm): 0.12-2.0mm (±0.02 mm)

- Length range (mm): Coil or according to your requirements

- Coatings: PE (polyester), SMP (silicone modified polyester), HDP (high durability polyester), PVDF (polyvinylidene fluoride).

What are the raw materials of ppgl steel

The raw materials of ppgl steel include: DX51D, DX52D, DX53D, SPCC, SPCD, Q235, DC01, DC02, etc.

Production process of ppgl steel

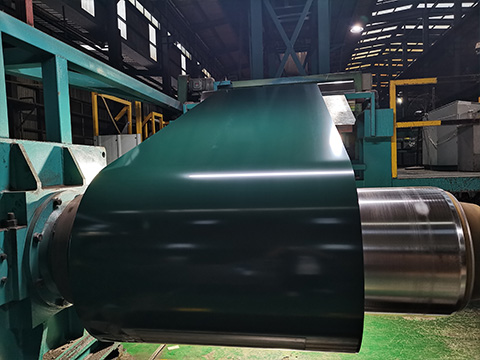

The production process of ppgl steel (Pre-painted Galvalume Steel) can be divided into two major sections: the production of aluminum-zinc coated steel sheets and the paint coating process.

Production process of aluminum-zinc coated steel sheets

Main processes: cleaning → annealing → hot-dip aluminum-zinc → flattening → tension straightening → chemical treatment → surface inspection → oiling, etc.

1. Cleaning

Remove the rolling oil remaining on the surface of cold-rolled steel and other surface dirt by mechanical brushing and electrolytic cleaning.

2. Continuous annealing

Recrystallize and anneal the cold-rolled steel that has been hardened after cold rolling to improve the microstructure and adjust the material properties.

3. Hot-dip aluminum-zinc

The coating thickness is controlled by an air knife. After the cold-rolled steel comes out of the zinc pot (55% aluminum, 43.4% zinc, etc.), it is induction heated to about 500°C for insulation to convert the zinc layer into an alloy phase.

4. Flattening

Flattening refers to rolling with a small deformation rate, which is to eliminate the material yield platform, improve the material mechanical properties, and improve the plate shape and surface quality.

5. Pulling and leveling

Further leveling the corrugated shape of the strip to obtain better straightness.

6. Chemical treatment

Apply a passivation or fingerprint-resistant coating on the surface of the coating, and perform drying and cooling treatment to achieve a surface treatment process that prevents rust and has conductivity, lubrication or other functions.

7. Surface inspection

Perform dimensional inspection, plate shape inspection and surface quality inspection, and record them.

Paint coating production process

1. Pretreatment process

Pretreatment is carried out after aluminum zinc plating. The pretreatment process is an effective means to improve the bonding force between the substrate and the coating.

2. Coating process

The color coating unit generally uses roller coating to apply the coating on the steel surface. Roller coating is a coating method that first forms a wet film of a certain thickness on the roller and then transfers this layer of coating to the surface of the strip.

- Primer coating: Apply a layer of primer on the surface of the steel plate. The main function of the primer is to enhance the adhesion and anti-corrosion performance of the coating.

- Topcoat coating: After the primer is dry, apply the topcoat according to customer requirements.

3. Curing

For the curing of the coating, the coated steel plate is sent into the curing furnace, and the coating is cured by chemical condensation, addition polymerization, cross-linking and other reactions through solvent evaporation to form a hard, wear-resistant and corrosion-resistant coating.

4. Processing technology

After curing, subsequent processing technologies include coating embossing, metal embossing, printing, laminating and other treatment methods. A protective film can also be applied or added to prevent PPGL steel from being scratched during transportation.

ppgl steel coil production video

PPGL steel uses

PPGL steel is widely used in construction, home appliances, transportation, home appliances, industrial equipment and other fields due to its good weather resistance, strong corrosion resistance and easy processing.

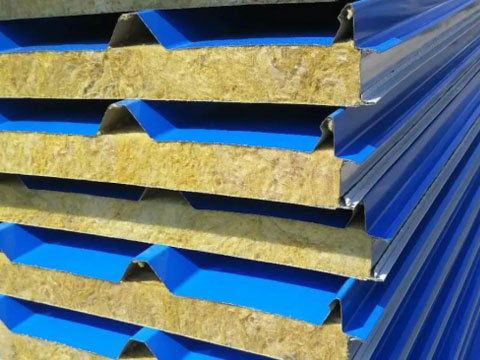

- Construction field: roof panels, exterior walls, ceilings, temporary buildings, etc.

- Home appliance field: shells, protective covers, etc. of air conditioners, microwave ovens, washing machines, refrigerators, etc.

- Transportation field: auto parts; interior and exterior decorative panels of trains and subway carriages, etc.

- Furniture field: panels and door panels of storage furniture such as wardrobes and bookcases.

- Industrial equipment: factory roofs, warehouse walls, ventilation systems, etc.

Which is better, PPGL steel or PPGI steel?

Comparison table of advantages and disadvantages of PPGL steel and PPGI steel

| PPGI | PPGL | ||

| Advantages | Disadvantages | Advantages | Disadvantages |

| Widely used: PPGI steel is widely used in construction, home appliances, automobiles and other fields, especially its good anti-rust performance and beautiful appearance make it the preferred material for building wall panels, roofs, warehouses, shopping malls and other buildings. | Relatively weak corrosion resistance: Although PPGI steel is also very corrosion resistant, its corrosion resistance is not as good as PPGL steel in some extreme environments. | Strong corrosion resistance: PPGL steel galvanized coating has excellent corrosion resistance and can maintain long-term use in harsh environments such as humidity and salt spray. | Higher price: Since the base material of PPGL steel, galvanized steel, is relatively expensive, the production cost of PPGL is relatively high. |

| Low cost: Compared with other corrosion-resistant steels, PPGI steel has a lower cost and is suitable for large-scale applications. | Good processing performance: PPGL steel has excellent processing performance and can meet various complex processing requirements. | The color is limited, and there are not as many colors as PPGI. | |

| Various colors: The surface of PPGI steel can be sprayed with paint of various colors, and the color selection of Wanzhi color-coated steel is based on the RAL color card. | Longer life: The life of PPGI is 20-30 years, and the life of PPGL is 2-3 times that of PPGI, with a longer service life. | ||

As can be seen from the above table: Both have their own advantages and disadvantages. Which one to choose depends on where you use it? What is the budget?

PPGI steel is more suitable for ordinary environments and has certain requirements for cost. PPGL steel has a wider application environment. If it is a harsh environment such as humidity and salt spray, it will be better to use PPGL steel.

ppgl steel price

The price of ppgl steel will be affected by factors such as raw materials, market supply and demand, specifications, zinc layer thickness, paint type, quantity, etc. The price will change every day. The reference price of ppgl steel is US$580-900 per ton.

- Thickness: The thinner the ppgl steel, the higher the price, because for the same tonnage of steel coils, the thinner the steel coils, the larger the area, the more paint will be used, and the more time will be required for production.

- Coating thickness: ppgl steel uses aluminum-zinc coating. The thicker the zinc layer, the higher the price.

- Paint type: ppgl steel paint types include PE, PVDF, HDP, and SMP. The prices of these four paints are different, and the paint is also affected by the brand. Consult us which paint is suitable for you.

- Quantity: Wanzhi Steel is a manufacturer specializing in the production of ppgl steel. ppgl steel is the factory wholesale price. The more quantity, the lower the price. The price discount for large-volume orders is greater.

What are the advantages of Wanzhi ppgl steel

- We conduct comprehensive quality inspections on ppgl steel to ensure the quality of ppgl products.

- There is one galvalume steel production line and three color coating production lines to ensure product delivery.

- We can customize the color according to your requirements. You can send samples to us and customize the color according to your samples.

- Our ppgl steel products include ppgl coils, ppgl plates, and ppgl corrugated roof panels. You are welcome to leave a message if you need that form of product.

- Our ppgl steel products have a long service life and high surface gloss, which can meet all your needs.

Conclusion

Wanzhi Steel is a factory. The ppgl steel sold is the factory wholesale price. The more the quantity, the cheaper the price. Wanzhi ppgl steel’s value-added services also include punching, profiling, cutting, printing, etc.

Wanzhi ppgl steel is exported to many countries, such as Turkey, Russia, Libya, Spain, Kenya, Peru, etc. If you are interested in ppgl steel, you are welcome to contact us at any time.