ppgi/ppgl steel

Product Introduction of ppgi/ppgl

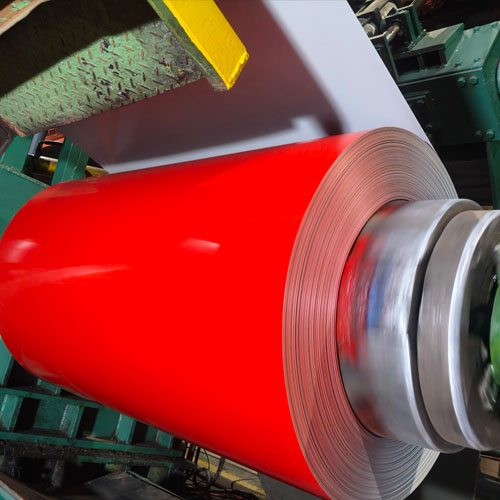

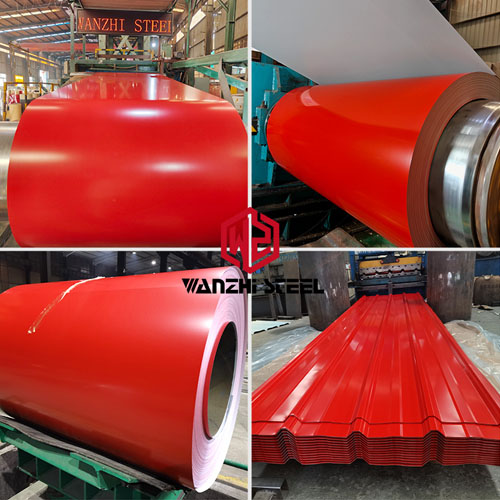

Wanzhi Steel is one of the famous manufacturers of PPGI and PPGL in China, with 3 advanced pre-painting production lines with an annual output of more than 320,000 tons. The PPGI/PPGL steels produced meet international standards and specifications.

Thickness: 0.13-2.0mm

Width: 600-1250mm or as your request

Colors: According to RAL color or your requirements

Paint Type: PE, SMP, HDP, PVDF

Processing Services: Punching, slitting, bending, uncoiling, customized samples, etc.

PPGI/PPGL available specifications

| Product Name | PPGI(Pre-Painted Galvanized),PPGL(Pre-painted Galvalume) |

| Material | Galvanized steel,Galvalume steel |

| Thickness | 0.13-2.0mm |

| Width | 600-1250mm or as your request |

| Length | According to your requests |

| Zinc Coating | 30-275g/m² or as required |

| Paint Type | PE(polyester), SMP(silicone-modified polyester), HDP(high-durability polyester), PVDF(polyvinylidene fluoride) |

| Colors | According to RAL color or your requirements |

| Surface type | Matte, texture, pattern, bright, etc.(Protective film can be applied) |

| Coil Weight | 3-6 tons/coil or as required |

| Processing Services | Punching, slitting, bending, uncoiling, customized samples, etc. |

| MOQ | 25 tons |

| Packing | Standard export packaging (waterproof paper inside and steel strap outside) |

| Payment Terms | EXW, FOB, CIF, CFR etc. |

| Standard | GB, AISI, ASTM, EN, JIS |

| Delivery Time | 15-25 working days after payment |

PPGI/PPGL product recommendation

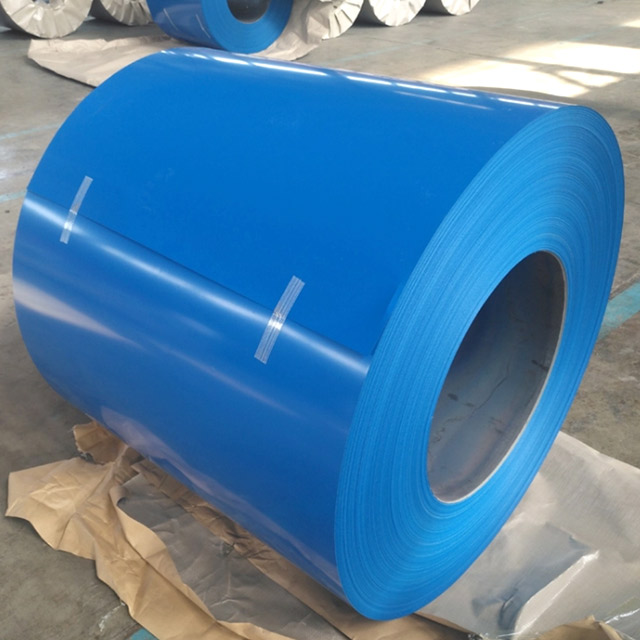

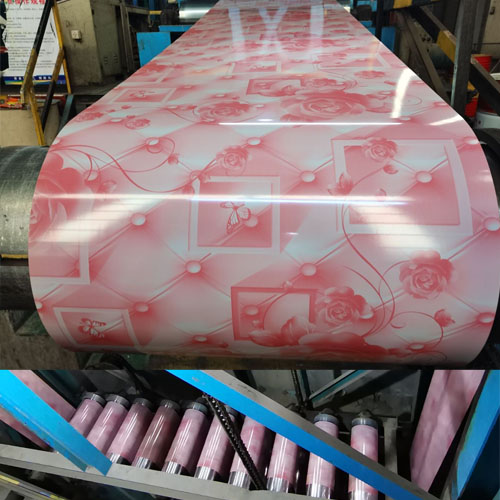

Both PPGI and PPGL are pre-painted steels with strong corrosion resistance, good weather resistance, strong decorative properties, and long service life. Wanzhi Steel produces a variety of specifications of PPGI and PPGL. The following are our key product recommendations.

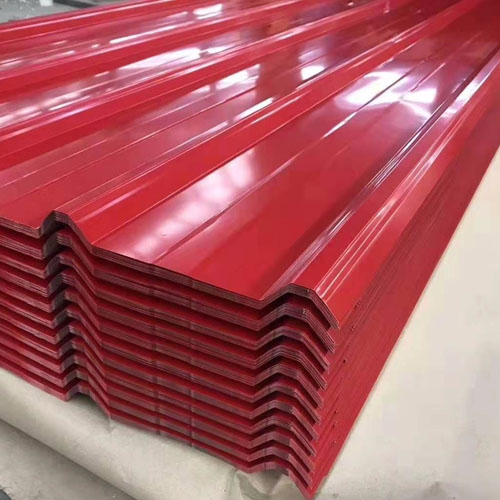

Application of ppgi and ppgl

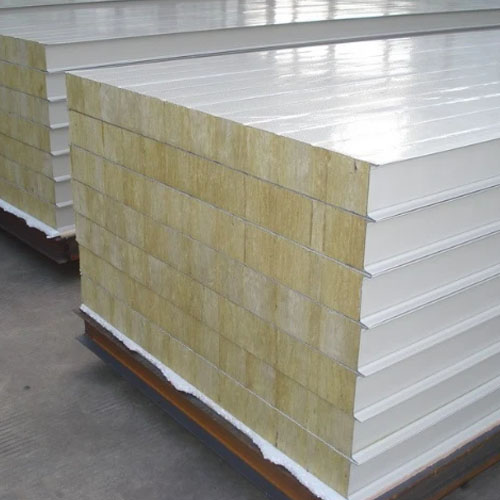

PPGI steel and PPGL steel are widely used. In the construction field, they are often used in roofs, building exterior panels, warehouses, shopping malls and other places. In addition, they are also used to manufacture various decorative panels. PPGI steel and PPGL steel are also commonly used in home appliance shells, car shells, public facilities, etc.

The application of PPGI steel and PPGL steel is not much different, but you need to pay attention to the application environment. PPGL steel has better corrosion resistance and weather resistance, and is more suitable for use in harsh environments (such as high salinity and high humidity areas).

Wanzhi product picture display

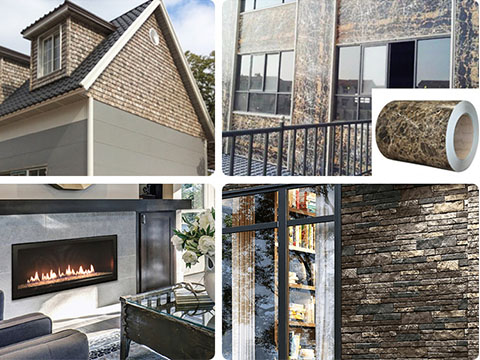

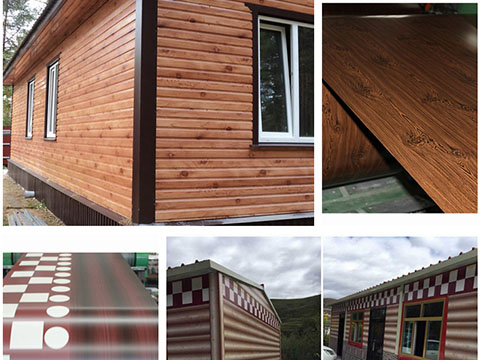

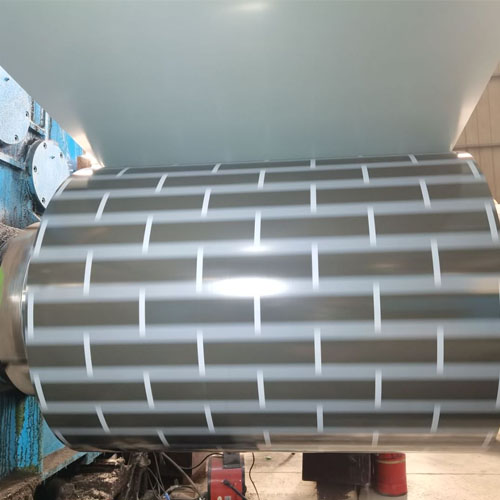

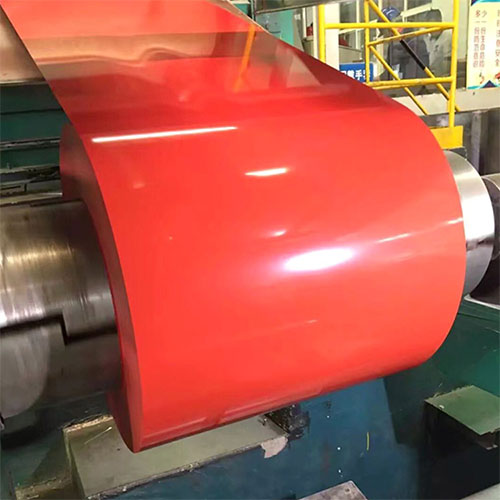

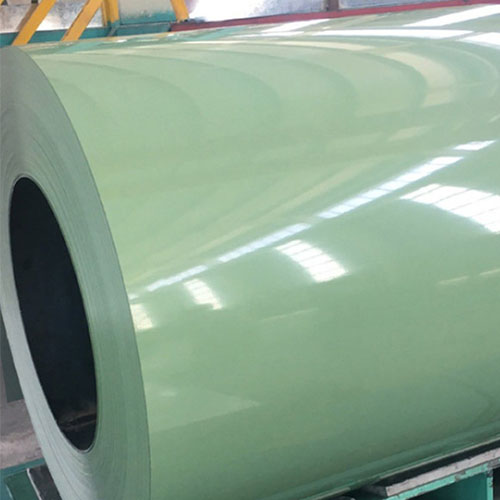

Wanzhi PPGI and PPGL surface designs include patterns, solid colors (matte, texture, glossy), these designs can be customized, you can send us samples and we will produce according to your requirements.

Pattern ppgi/ppgl products

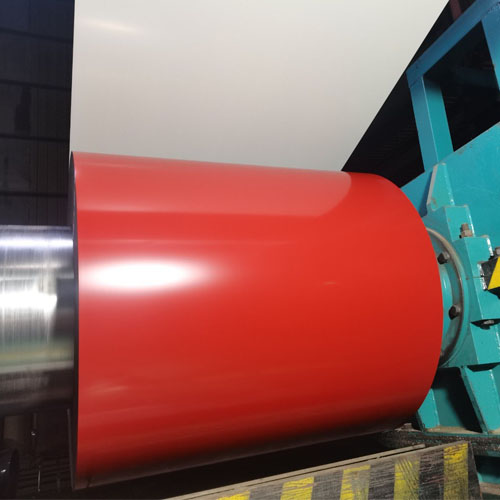

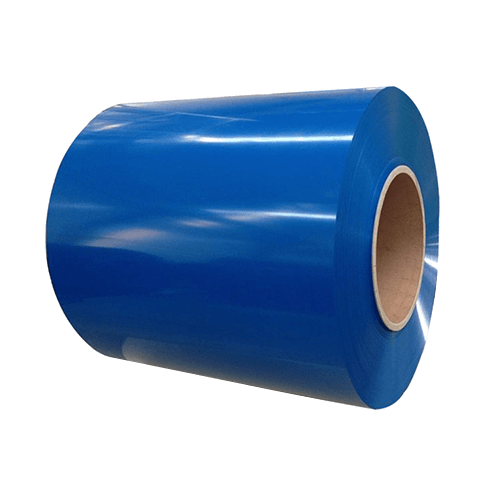

Solid color ppgi/ppgl products

If you have any needs for PPGI/PPGL related products, please contact us to confirm product details and obtain accurate price information.

Production Video

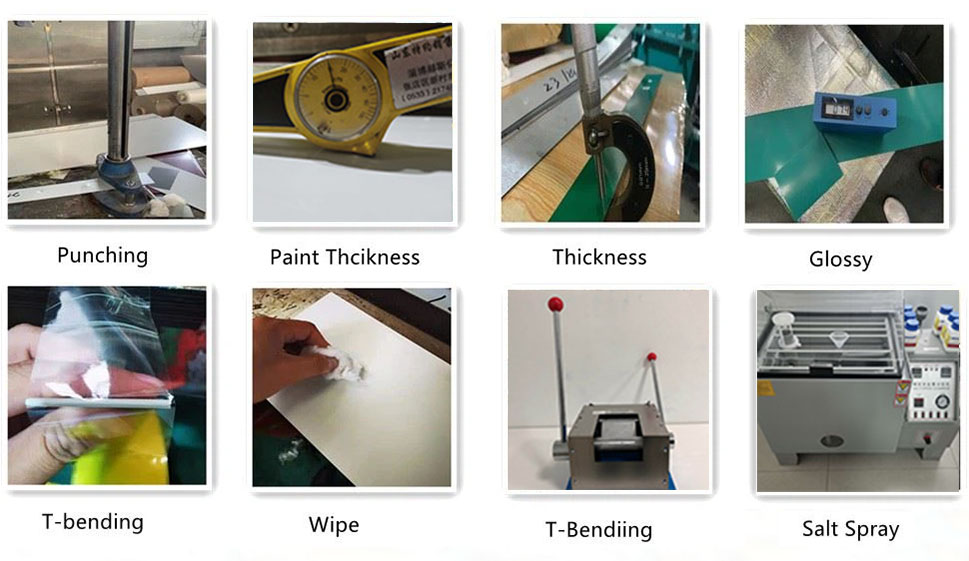

ppgi/ppgl quality inspection

Wanzhi PPGI/PPGL product quality inspection includes: impact resistance test, steel thickness and coating thickness test, gloss test, T-bend test, erasure test, and salt spray test (to test the corrosion resistance of the product).We can also accept third party testing

FAQ about PPGI/PPGL

A: The most obvious difference lies in the base materials: PPGI uses galvanized steel as its base material, while PPGL uses galvanized aluminum-zinc steel.

Another difference is in corrosion resistance: PPGL offers better corrosion resistance than PPGI, but it is also more expensive.

Application Recommendations → PPGI is more suitable for general buildings, interior decoration, and appliance casings, while PPGL is more suitable for coastal/high-humidity regions, high-temperature environments, and high-end buildings.

If the environment is heavily polluted or corrosive, it is recommended to use color-coated steel with ZAM steel as the base material.

A: Whether to choose PPGI or PPGL depends mainly on the budget of your project and the scenario in which the product is used.

If the environment is relatively harsh, such as humid coastal areas, it is recommended to choose PPGL with better corrosion resistance, which can maintain a good service life in humid environments; if the product is used in ordinary environments, or the service life of the product is not required, it is recommended to use PPGI; and if the budget is not very high, it is recommended to use PPGI, because PPGI’s corrosion resistance is also relatively strong.

A: Processing such as bending, stamping, and cutting can be performed to produce corrugated steel sheets, perforated steel sheets, color-coated sandwich panels, etc., which are used in scenarios such as garage doors, gutters, roofs, and wall panels.

A: The HS code of PPGI/PPGL is 7210 6100 00, which refers to wide flat rolled products of iron plated or coated with aluminum-zinc alloy.

The HS code of PPGI is 7210 7010 00, which refers to flat rolled products of iron or non-alloy steel with a thickness of less than 1.5 mm and a width of not less than 600 mm.

A: We provide samples for free, but you need to pay for the postage.

A: Our delivery time depends on the order quantity, typically ranging from 5 to 30 working days.

A: Price terms include FOB (Free On Board), CIF (Cost, Insurance, and Freight), CFR (Cost and Freight), and EXW (Ex Works); currently, only TT (Telegraphic Transfer) is accepted as a payment method.

More Related Products

Product Category

Coated Steel

- GALVANIZED STEEL COIL

- GALVALUME STEEL

- HOT DIP GALVANIZED STEEL

- ELECTRO GALVANIZED STEEL

- GALVANIZED CORRUGATED ROOF SHEET

- ZAM STEEL

Color coated steel

- PPGI STEEL COIL

- CORRUGATED STEEL SHEETS

- PPGL

- PATTERN PPGI

- PREPAINTED STEEL SHEETS

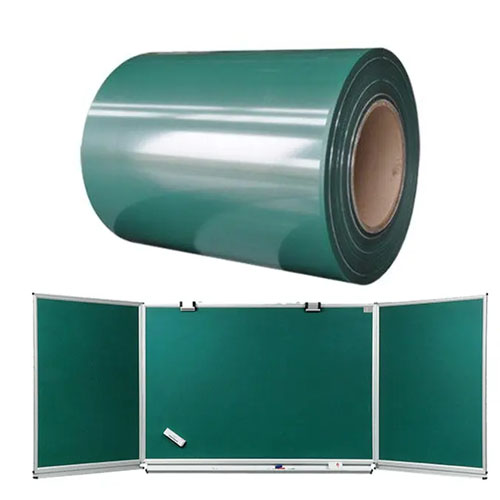

- PPGI FOR WRITING BOARDS

- PPGI FOR FENCE

- PPGI FOR HOME APPLIANCES

- PREPAINTED ALUMINUM COIL

- MATT TEXTURED PPGI

- COLOUR COATED ROOFING SHEET

Roofing Sheet

Stainless Steel

Other Coil & Sheet

- COLD ROLLED COILS

- HOT ROLLED STEEL

- EMBOSSED STEEL

- METAL CARVED PANEL

- COLD ROLLED STEEL SHEET

- PERFORATED SHEET METAL

- Q235 STEEL

Industry knowledge

- Different Stainless Steel Finishes on Home Appliances

- How to Choose PPGI Coating

- Factors Affecting the Price of Color-coated Steel (PPGI/PPGL)

- What is Color Steel Sandwich Panel?

- Pvdf Coating

CONTACT US

- Mobile: +8617637100809

- Whatsapp: +8615138685087

- Email: info02@wanzhisteel.com

- Address: 10F, Building B, Erqi Center, Erqi District, Zhengzhou City, Henan Province, China