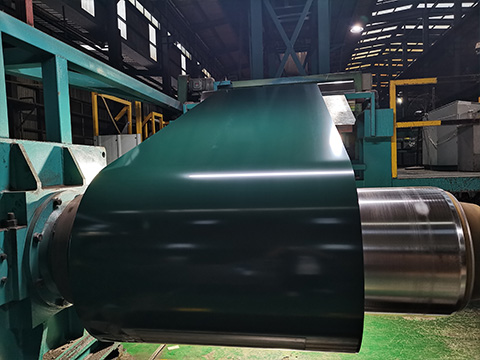

PPGI stands for Pre-Painted Galvanized Steel. Its core performance is based on the substrate (galvanized layer) and the paint coating (organic coating). Choosing the right substrate coating and paint coating for your project can not only save costs but also ensure the service life of the project.

Before making a choice, consider these two questions:

- What environment will the final product be used in? — For example: dry indoor environments, outdoor atmospheric environments, high-humidity industrial areas, coastal environments with high salt spray, etc.

- What functions does the product need to perform? — For example: deep stamping, building roofs/walls, appliance housings, furniture, etc.

Different needs will lead to different requirements for substrate coatings and paint coatings. With these questions in mind, let’s examine the characteristics of substrate coatings and paint coatings and their applicable scenarios.

Substrate Coating

Coating Weight Selection

Coating weight is typically expressed in grams per square meter (g/m²), measured on both sides. The higher the value, the thicker the zinc coating, the longer the corrosion resistance life, and the higher the cost.

Common Coating Types (GI): Common coating types include Z60 (60g/m²), Z90 (90g/m²), Z120 (120g/m²), Z180 (180g/m²), and Z275 (275g/m²).

How to Choose?

- Indoor dry environments: Z60-Z90 is generally sufficient (e.g., office furniture, appliance internals).

- Outdoor normal atmospheric conditions: Z120-Z150 is recommended (e.g., building wall panels).

- High humidity and high salt spray environments: Z180 or higher is recommended, or directly choose AZ coating (e.g., coastal buildings, roof panels).

Substrate Material Selection

Different substrate materials have different mechanical properties (yield strength, tensile strength, and elongation).

| Grade (Standard) | Classification | Features and Applications |

| DX51D (EN) SGCC (JIS) CGCC (JIS) CS Type A/B (ASTM) | General Use | This product offers a perfect balance of excellent formability and cost-effectiveness, meeting most basic processing needs. |

| DX52D (EN) SECC (JIS) | Mechanical Seam/Modified Forming | Higher fatigue resistance and bending performance make it suitable for processes requiring repeated bending or seaming, preventing cracking. |

| DX53D (EN) | Deep Drawing | Excellent deep-drawing properties reduce the risk of cracks and surface defects during complex forming, providing high processing stability. |

| S250GD (EN) S350GD (EN) | High Strength Structure | Excellent deep-drawing properties reduce the risk of cracks and surface defects during complex forming, providing high processing stability. |

| S550GD (EN) | Ultra-High Strength | Extremely high strength and hardness provide excellent resistance to compression and deformation, but with lower formability. |

Paint Coating

The paint coating is the outer layer of PPGI, directly exposed to the external environment and determining the product’s appearance, color, weather resistance, and other aspects.

Paint Types, Characteristics, and Applicable Environments

| Paint type | Key Features | Applicable Environments | Cost |

| PE | Highest value for money, excellent flexibility and processability, and a wide range of colors. However, weather resistance is average. | This coating is currently the most commonly used for indoor applications and building sidewalls in standard outdoor environments. | Low |

| HDP | A modified version of PE, its weather resistance (especially chalking resistance) is significantly superior to standard PE. | It is a popular choice for roofs and walls in outdoor projects where color durability is a priority. | Medium |

| SMP | Improved with silicone resin, it offers improved heat resistance, stain resistance, and durability, but slightly less flexibility. | It is suitable for buildings requiring high stain resistance and heat resistance. | Medium |

| PVDF | Improved with silicone resin, it offers improved heat resistance, stain resistance, and durability, but slightly less flexibility. | It is also suitable for high-end landmark buildings, projects in harsh maritime climates, and projects requiring extremely high color consistency. | High |

Paint Coating Structure

- Top Side: Typically, a two-coat, two-bake structure (primer + topcoat) is used. The primer provides adhesion and substrate protection, while the topcoat provides color and weather resistance.

- Back Side: A single coat of paint (standard epoxy backcoat) provides basic protection; a two-coat paint (thicker backcoat) provides enhanced protection and is suitable for high-humidity environments (such as cold storage equipment and the backsides of buildings).

Paint Coating Thickness

Coating thickness (both front and back) is also an important specification, typically expressed in microns (μm). The higher the thickness, the better the physical barrier protection.

- General Applications: 20-25μm for the front, 5-8μm for the back.

- Severe Environments/High Performance Requirements: 25μm or more for the front, with thicker thickness available for the back.

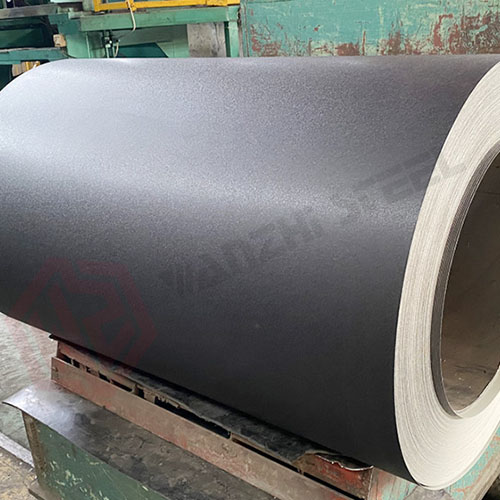

Color and Surface Texture

- Color: Select based on design requirements. Note that dark colors (especially black and dark blue) absorb heat more strongly, placing higher demands on the coating’s heat resistance and durability. They may also cause the substrate to expand and contract more significantly.

- Texture: wrinkled, smooth, matte, wood grain, stone, etc. Texture not only affects the appearance, but also the touch and stain resistance.