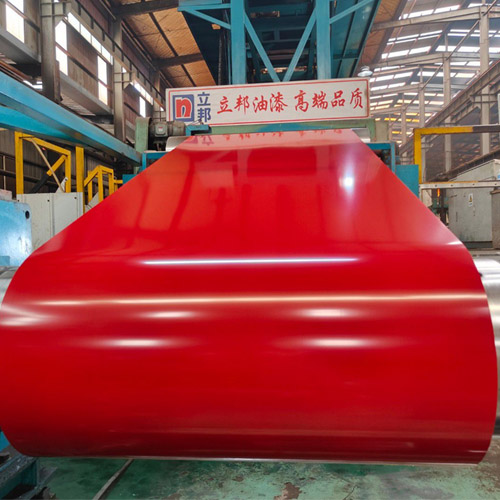

Color coated steel is made of galvanized steel or aluminum-zinc-coated steel as the substrate. After surface pretreatment (degreasing and chemical treatment), a layer of organic coating is applied on the surface of the substrate by roller coating, and then baked and cooled.

Table of Contents

- Determine project requirements

- Understand the performance of color coated steel

- Evaluating Costs

- Selection of reliable suppliers

- Wanzhi Steel Advice

- Wanzhi Steel-China’s most professional manufacturer of color coated steel

Color coated steel has various colors, rich patterns, beautiful appearance, strong corrosion resistance, good processing performance, and is widely used in construction, furniture, home appliances and other industries. How should color-coated steel be selected for specific projects? This article mainly explains how to choose the right color-coated steel for your project?

Determine project requirements

1. Usage Scenario

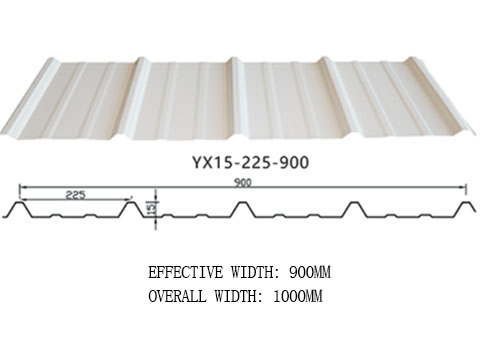

- Determine which part of the building the color-coated steel will be used in (e.g., exterior walls, roofs, etc.) or whether it will be used in appliances, furniture, automobiles, etc.

- Consider the climatic and environmental conditions of the project site, such as temperature, humidity, corrosive substances, etc.

If you consider temperature, for example, light colors keep buildings cool and reflect sunlight. Dark colors warm buildings because they absorb heat.

2. Performance Requirements

After determining the usage scenario, consider what the usage scenario requires in terms of the performance of the color coated steel, such as corrosion resistance, aesthetics, and mechanical properties.

- Corrosion resistance: According to the climatic and environmental conditions of the project location, determine the requirement of corrosion resistance.

- Aesthetics: whether the color, pattern, texture, etc. of the color coated steel surface matches the overall design style of the project.

- Mechanical properties: Consideration of mechanical properties is mainly to ensure that the color coated steel can meet the structural requirements of the project.

Understand the performance of color coated steel

1. Coating performance

Coating types

Understand the characteristics of different coatings (PE, SMP, HDP, PVDF) and applicable scenes.

For example, PE coating is inexpensive and many products, easy to process molding, color and gloss of the choice of a large margin, but ultraviolet resistance and chalking resistance is not ideal.

PVDF coatings have very good corrosion resistance and color retention, ultraviolet resistance and heat resistance is also very outstanding, is the construction of industrial use of color coated steel coatings in the highest level of products.

Coating thickness

The thicker the coating, the better the corrosion resistance, but the price will also increase.

Coating Adhesion

Ensure a strong bond between the coating and the substrate to avoid coating peeling off during use.

2. Substrate properties

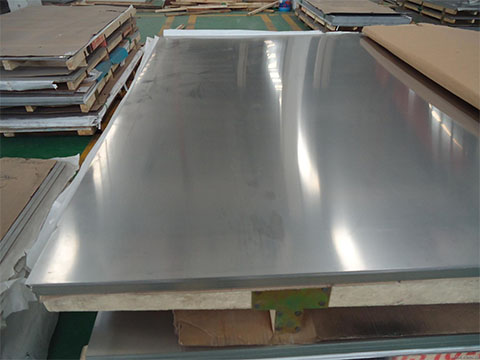

Types of substrates

There are generally two types of substrates for architectural color coated panels, hot-dip galvanized panels and aluminum-zinc coated panels. Pure zinc outperforms aluminum-zinc alloys in alkaline media, and the opposite is true in acidic media. Therefore, aluminium-zinc plated colour coated steel should be used in relatively acidic environments and galvanized colour coated steel should be used in relatively alkaline environments.

Substrate Thickness

Select the appropriate substrate thickness according to the project structure and load bearing requirements.

3. Other properties

Processing performance

Consider whether the processing performance of the color coated steel, such as shearing, bending, drilling, etc., meets the needs of the project.

Fire resistance

Select color coated steel with appropriate fire resistance according to project requirements.

Evaluating Costs

- Material cost: Determine the material cost based on factors such as the type of coating, substrate type and thickness of the color coated steel.

- Processing cost: Consider the processing cost of cutting, punching, welding, etc. of the color coated steel.

- Transportation and installation costs: evaluate transportation and installation costs based on the geographic location and scale of the project.

Selection of reliable suppliers

- Brand reputation: choose manufacturers with strength and reputation to ensure product quality and after-sales service.

- Production capacity: Understand the production scale and technical level of the supplier to ensure that it can meet the needs of the project.

- Product certification: Check whether the products have passed relevant quality certifications, such as ISO9001 quality management system certification.

- Service support: Find out whether the supplier provides commitments in terms of technical support, delivery time and after-sales service.

Wanzhi Steel Advice

Wanzhi Steel’s suggestions for using color-coated steel for projects are as follows:

| Project | Substrate | Coating (g/㎡) | Paint | Paint thickness | Reason |

| National key projects: public buildings such as stadiums, high-speed rail stations, and exhibition halls. | Galvalume steel, Galvanized steel | AZ150,Z275 | PVDF Or HDP | Front coating 25um is enough | Public buildings are highly visible and close to each other, so color-coated steel plates need to be beautiful and durable. |

| Non-ferrous metal smelters, steel mills, power plants, etc. | Galvanized steel | The double-sided zinc layer is recommended to be no less than 120g/㎡ | PVDF Or HDP | The front coating is not less than 25μm | The use environment has particularly high requirements for the corrosion resistance of color-coated steel. |

| Arched roofs (sports stadiums, trading markets, exhibition halls, warehousing and logistics, etc.). | Yield strength is 280-550Mpa | The double-sided zinc layer is recommended to be no less than 120g/㎡ | PVDF,HDP,PE | The front coating is not less than 20μm | The strength requirements for color-coated steel are relatively high. |

| Temporary offices, accommodation, guard booths and other activity rooms at construction sites. | Galvanized steel | Ordinary zinc layer | PE | The thickness of the front coating is 15-20μm | While ensuring safety, more consideration should be given to economic practicality and cost. |

| Ordinary industrial plant. | Galvanized steel | Double-sided zinc layer of substrate 80g/㎡ | PE | The thickness of the front coating is 20μm | The requirements for the corrosion resistance and aging resistance of the color steel plates are not high, and more consideration is given to the practicality and cost-effectiveness of factory construction. |

| Coastal areas with high salt fog. | Galvalume steel, Galvanized steel | AZ150,Z275 | PVDF Or HDP | The front coating is not less than 25μm | The main consideration in the selection of color steel plates is corrosion resistance. |

| Areas with severe sandstorms. | Galvanized steel | The double-sided zinc layer is recommended to be no less than 120g/㎡ | SMP | The front coating is not less than 20μm | Areas with severe sandstorms require the coating to be hard, wear-resistant and non-powdering. |

| Areas with strong ultraviolet radiation. | Galvanized steel | The double-sided zinc layer is recommended to be no less than 120g/㎡ | PVDF Or HDP | The front coating is not less than 20μm | The main consideration is the UV resistance of the coating. |

| Residential | Brick, wood, marble and other printed color-coated steel | When using color steel plates on exterior walls and roofs, we must consider features such as beauty, individuality, and naturalness. | |||

Wanzhi Steel-China’s most professional manufacturer of color coated steel

- The enterprise is ISO 9001:201 certified, with 13 years of export experience, serving more than 120 countries, high customer ratings, and high repurchase rate of products.

- With two color coated steel production lines and two written steel plate production lines, the annual production is 60w tons, which can meet the demand of any scale project, and has enough production capacity for large quantity orders.

- With a professional testing center and more than 20 professional inspectors, we will carry out a comprehensive inspection on the color coated steel before leaving the factory, including performance, appearance, specification and so on. We also support third party testing.

We have rich and professional experience in the field of color coated steel, if you have any questions about color coated steel, please feel free to contact us, we guarantee to answer you within 12 hours.