Stainless steel finds extensive application in the home appliance sector due to its exceptional corrosion resistance, hygienic properties, and ease of cleaning. Additionally, stainless steel offers numerous surface finishes with diverse functionalities and strong decorative appeal. Join Wanzhi Steel as we explore stainless steel finishes used in the home appliance industry.

Functional Finishes

Fingerprint-Resistant Stainless Steel

- Finishing Process: A transparent nano-scale organic coating is applied over base finishes like brushed or sandblasted surfaces.

- Functional Principle: The acrylic composite resin-based coating contains silane-modified nano-fillers. After curing, it forms a 1-10μm thin film, reducing surface energy below 35mN/m to minimize fingerprint oil adhesion.

- Functional Advantages: Reduces fingerprint residue by 80% and lowers cleaning frequency by 50%; coating hardness reaches 3H (750g load), with salt spray resistance ≥1000 hours, ensuring durability.

- Appliance Applications: High-touch areas like refrigerator doors, built-in oven doors, dishwasher panels, range hoods, etc.

Antibacterial Stainless Steel

- Finishing Process: Silver ions are integrated into the coating layer during PVD deposition. These ions disrupt bacterial cell membranes and inhibit respiration, delivering long-lasting antimicrobial effects.

- Functional Principle: Slowly released metal ions form an ultra-smooth oxide layer (Ra ≤ 0.4μm), minimizing bacterial adhesion gaps. The oxide layer itself exhibits antibacterial properties, achieving >99.9% E. coli elimination rate.

- Functional Advantages: Long-lasting antibacterial properties, safe and eco-friendly. Often combined with fingerprint-resistant coatings or PVD color finishes for multifunctional integration.

- Appliance Applications: Direct food contact components such as soy milk maker inner pots, coffee machine brewing chambers, rice cookers, kettles, etc.

Decorative Finishes

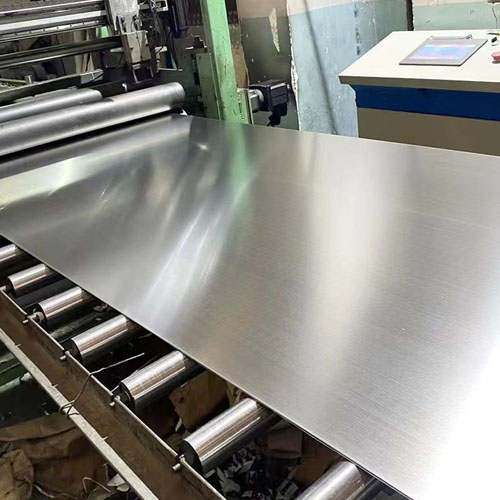

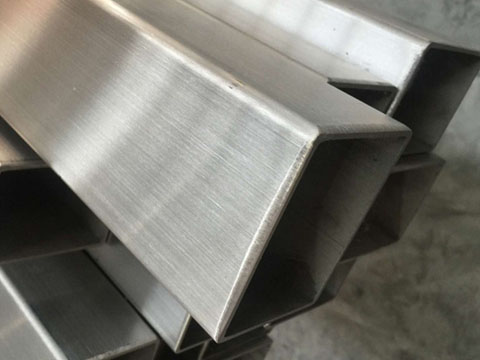

Brushed Finish Stainless Steel

- Process Type: Brushing (HL process), categorized as straight brushed (hairline) or random brushed.

- Decorative Characteristics: Straight brushed features fine, dense vertical lines with a satin luster, conveying simplicity and elegance; random brushed exhibits irregular, interwoven patterns resembling fabric textures with lower gloss levels (≤30 GU).

- Appliance Applications: Refrigerator panels, ovens, washing machine bodies (random brushed).

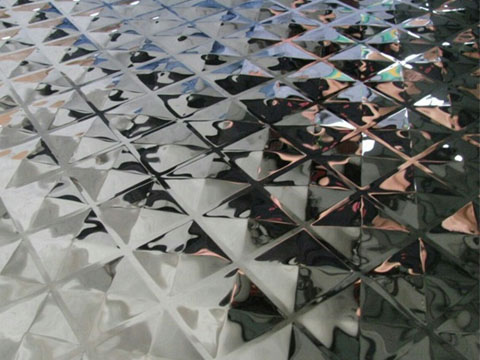

Embossed/Raised Finishes

- Process Type: Molding techniques create three-dimensional patterns like diamonds, water ripples, or geometric shapes.

- Decorative Features: Embossing produces deep, textured reliefs (diamond patterns, leather grain) with strong dimensionality.

- Appliance Applications: Refrigerator doors, washing machine tops/doors, oven doors, etc.

Etched Stainless Steel Finish

- Process Type: Chemical etching creates patterns including diamonds, squares, wavy lines, wood/stone textures, etc.

- Decorative Features: The etching process creates deep, textured patterns (e.g., brand logos, water ripples) with pattern precision down to 0.1mm, enabling gradient effects.

- Appliance Applications: Appliance identification areas, refrigerator door panels, range hood panels, oven doors, etc.

Mirror-Finished Stainless Steel

- Process Type: Mirror polishing (6K, 8K grade)

- Decorative Features: Mirror-like surface clarity with high reflectivity of surroundings and exceptional gloss.

- Appliance Applications: Oven doors, steam oven doors, range hood covers, coffee machine handles, refrigerator door handles, etc.

Sandblasted Stainless Steel

- Process Type: Sandblasting treatment.

- Decorative Features: Uniform bead-blasted matte finish (gloss ≤15GU) with a finely textured tactile feel.

- Appliance Applications: Air fryer control panels, dishwasher door panels, etc.

Colored Stainless Steel

- Process Type: Physical Vapor Deposition (PVD) technology.

- Decorative Features: Achieves metallic hues like champagne gold, rose gold, deep space gray, titanium black, etc. PVD color films resist UV exposure and aging, ensuring long-lasting, fade-resistant color.

- Appliance Applications: Refrigerator/wine cabinet doors, premium rice cookers, high-speed blenders, coffee machines.

The stainless steel finishes for modern high-end appliances represent the perfect integration of “functional coatings + decorative substrates,” such as:

- Brushed/sandblasted + fingerprint-resistant coating.

- PVD Champagne Gold + Antibacterial Coating.

- Embossed Texture + Self-Cleaning Coating.

When selecting stainless steel coils for appliances, we must consider the functional and decorative requirements of different application scenarios to choose the most suitable stainless steel coil for appliance manufacturing.

Why Choose Us?

For appliance manufacturers, we supply any steel material you require. Beyond diverse stainless steel products, we offer film-laminated metal sheets—products featuring various films bonded to steel substrates. These offer lower costs than stainless steel, enhanced functionality, and exceptional durability.

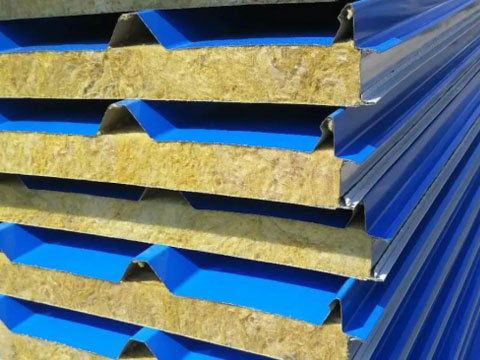

Film Laminated Metal Sheet Products Include:

We provide comprehensive solutions for all your appliance steel needs. For any inquiries regarding appliance steel materials, please contact us anytime.