Customer Background

The client is a UAE-based material supplier specializing in light steel construction and container conversion with 8 years of experience. Their operations span major cities including Dubai, Abu Dhabi, and Sharjah, while also extending to neighboring countries such as Saudi Arabia and Qatar. The company primarily deals in color-coated steel coil, light steel studs, container conversion accessories, and related products.

Communication Process

The customer inquired about our service via email through the product page on our official website, https://wanzhi-steel.com/. After receiving the email, we found that the customer’s order breakdown was quite complex. Based on the customer’s needs, we provided a specific and feasible solution:

1. Slitting Plan and Process Feasibility Verification

Our technical team first calculated the yield rate and verified that the sum of all narrow strip widths precisely matched the parent coil width (1250mm) to prevent customer design errors. Only after confirmation did we provide a technical quotation based on processing the parent coil width into strips.

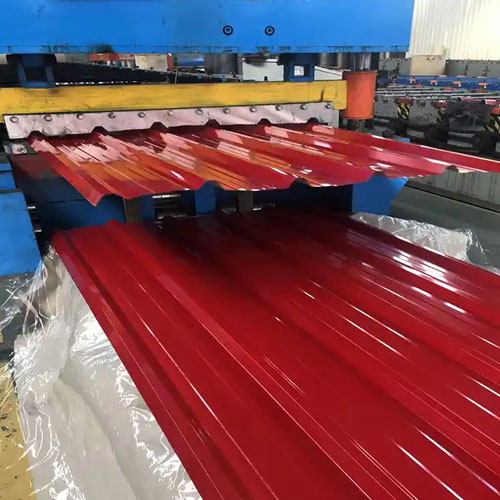

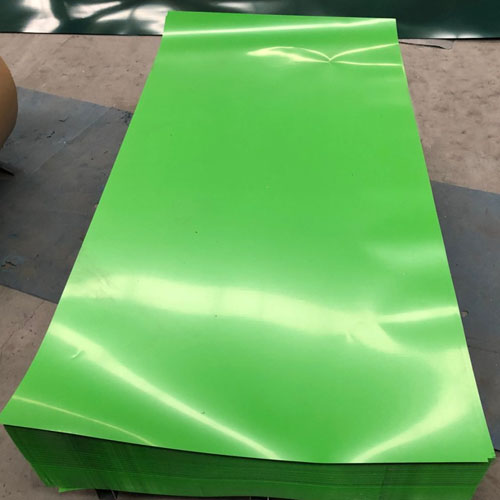

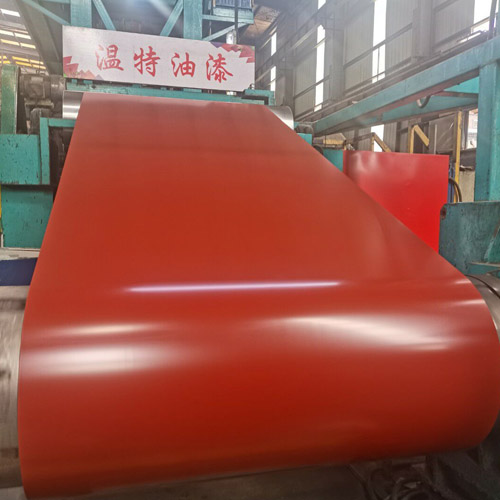

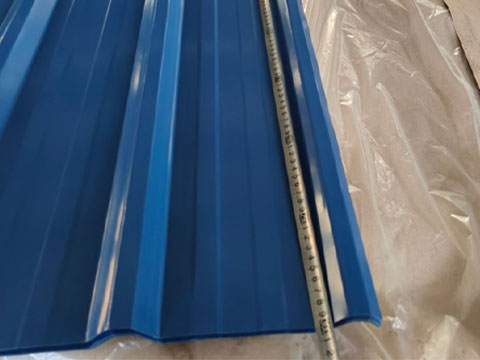

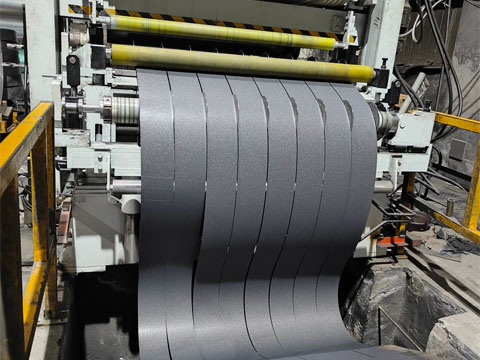

Note: As this customer has just signed a contract with us, production has not yet been completed. The image shows our previously manufactured color-coated steel strip.

2. Optimization Plan

We observed that when slitting multiple narrow strips from 0.25mm thin sheets, the innermost strip (e.g., 70mm) may exhibit “curling” or “sickle bending.” To address this, our production department proposed the following solutions:

- Employing specially designed high-precision, small-diameter circular blades for slitting to minimize stress.

- Incorporate a mild “tension straightening” process post-slitting to ensure flatness of each narrow strip.

3. Establishing a Dedicated “Nesting-Slitting-Packaging” Workflow

We designed a specialized production process for this project:

- Merge orders of identical colors (e.g., two RAL 9005 orders) into a single production run, utilizing the same master coil for continuous nesting and slitting.

- After slitting, narrow strips of different widths are co-wound onto the same core (i.e., multiple narrow strips are wound onto the same mandrel) and packaged strictly by order, with composite labels affixed containing all specification and length details.

- This ensures each package corresponds to a complete “material kit,” enabling highly convenient on-site retrieval.

After reviewing our proposal, the client expressed admiration for our professionalism, noting we were the most meticulous and thorough manufacturer among all their contacts. All communication was detailed and comprehensive. The client plans to purchase 100 tons initially, with potential for larger orders if product quality meets expectations!

Order Details

| Procurement Products | PPGI Strip |

| Substrate | DX51D+Z30 |

| Coating | Matte Polyester Coating, Film Thickness 18µm (Front) / 10µm (Back) |

| Procurement Country | UAE |

| Order 1 | Master Roll: 0.25mm x 1250mm |

| Slitting Scheme: 70mm*6 strips + 90mm*7 strips + 200mm*1 strip | |

| Color: RAL 9005 | |

| Quantity: 25 tons | |

| Order 2 | Master Roll: 0.25mm x 1250mm |

| Slitting Scheme: 70mm*5 strips + 90mm*10 strips | |

| Color: RAL 9005 | |

| Quantity: 25 tons | |

| Order 3 | Master Roll: 0.25mm x 1250mm |

| Slitting Scheme: 70mm*6 strips + 90mm*7 strips + 200mm*1 strip | |

| Color: RAL 9010 | |

| Quantity: 25 tons | |

| Order 4 | Master Roll: 0.25mm x 1250mm |

| Slitting Scheme: 6 rolls of 70mm + 5 rolls of 90mm + 1 roll of 145mm + 1 roll of 220mm | |

| Color: RAL 7016 | |

| Quantity: 25 tons | |

| Total Quantity | 100 tons |

| Key Process Requirements | 1. High-precision combined slitting, width tolerance ±0.2mm. |

| 2. Thin sheet shape control to ensure no curling or waviness in the narrow strips after slitting. | |

| 3. Co-roll packaging: The slitting narrow strips are combined, rolled, and packaged according to the order. | |

| Packaging & Labeling | Standard export packaging, each package has a detailed specification list and color code affixed to the outside. |

| Delivery Time | As agreed in the contract |

| Trade Terms | CIF (Port of Destination: Jebel Ali Port, UAE) |

| Payment Method | 30% prepayment + 70% balance (payable against copy of bill of lading) |

Why Choose Us?

- We integrate all processes—decoiling, color coating, high-precision slitting, and co-roll packaging—eliminating secondary processing time and saving customers valuable time.

- Equipped with advanced production facilities and technical expertise in ultra-thin specifications, we meet stringent customer requirements.

- Beyond color-coated coil production lines, our diverse processing equipment enables efficient handling of large-volume orders.

Wanzhi Steel is a professional manufacturer of color-coated steel coils. Headquartered in Binzhou City, Shandong Province, China, we have over 15 years of experience and export products to more than 120 countries. In addition to PPGI steel strips, we offer the following related products:

If you have any requirements for color-coated steel products, please feel free to contact us.