Stainless steel has a wide variety of finishes. Through different surface treatment processes, its appearance, texture and performance can be changed to enhance decorativeness, corrosion resistance or other functions to meet the various needs of different applications.

Table of Contents

- Stainless Steel Finish Types

- Application of Different Finishes

- What are the Surface Treatment Methods of Stainless Steel?

- Recommendations for Choosing Different Finishes

- Conclusion

Stainless Steel Finish Types

| Finish types | Production process steps | Features | Key parameters/materials |

| Mirror (No.8) | High polishing: coarse grinding → medium grinding → fine grinding → polishing (cloth wheel + chromium oxide paste) | Highly reflective, no obvious scratches | Surface roughness Ra≤0.05μm, reflectivity ≥85% |

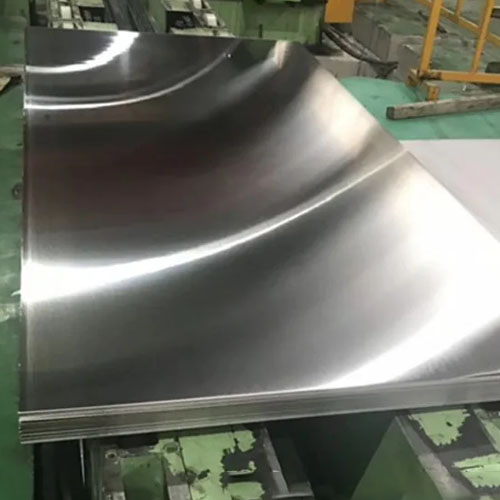

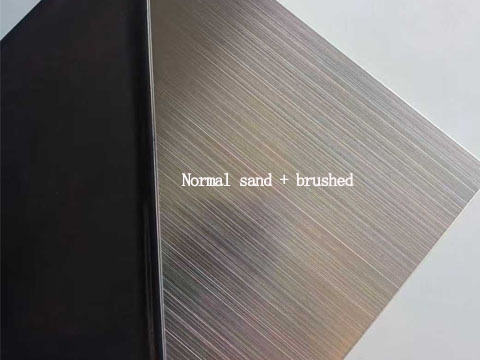

| Brushed (HL) | Mechanical friction (sandpaper/nylon belt directional grinding) | Hair-like texture, low reflectivity | Texture depth 5-15渭m, common straight/random lines |

| Sandblasted (SB) | High-pressure spraying of sand/glass beads | Uniform frosted texture, matte effect | Grit size 80-220 mesh, surface roughness Ra1.5-3μm |

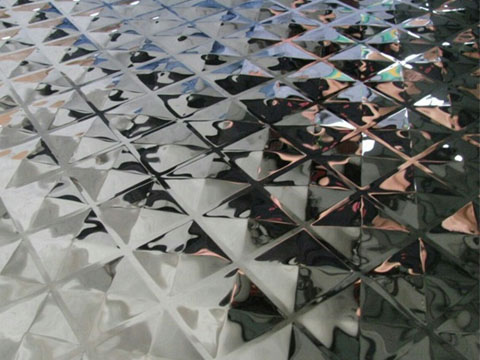

| Embossed finish | Mechanical embossing of three-dimensional patterns (diamonds, squares, etc.) | Three-dimensional texture, unique touch | Mold depth 0.1-0.5mm, customizable anti-slip lines |

| Acid-washed passivation | Sulfuric acid/hydrofluoric acid soaking → water washing → neutralization | Basic corrosion-resistant surface, surface Ra is about 0.8-1.6μm | Acid concentration 10-20%, temperature 60-80℃ |

| Chemical coloring | High-temperature oxidation (blackening) or chemical solution soaking (blueing) | Dark surface, wear-resistant and beautiful | Blackening temperature 550-600℃, blueing solution contains sodium hydroxide |

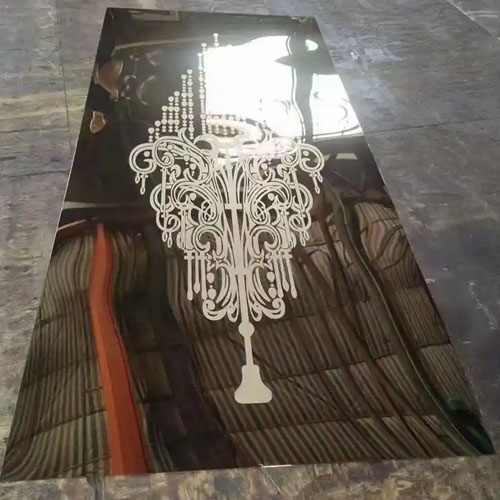

| Etched finish | Electrochemical etching, electrolytic corrosion | Surface has patterns or textures, and patterns can be customized | Electrolyte contains NaCl/HCl, voltage 5-15V |

| PVD coating | Physical vapor deposition of metal film (titanium/zirconium) under vacuum | Color coating, strong decorative effect | Coating thickness 0.3-1渭m, color adjustable (gold/rose gold/black titanium) |

| Anti-fingerprint coating | Nano-fluorocarbon coating | Hydrophobic and oleophobic, reduces fingerprint residue, easy to clean | Coating thickness 5-10μm, contact angle ≥110° |

| Antibacterial coating | Deposition of silver ions or photocatalytic TiO₂ | Inhibit bacterial growth, suitable for medical environments | Silver ion concentration 1-5%, TiO₂ particle size 10-50nm |

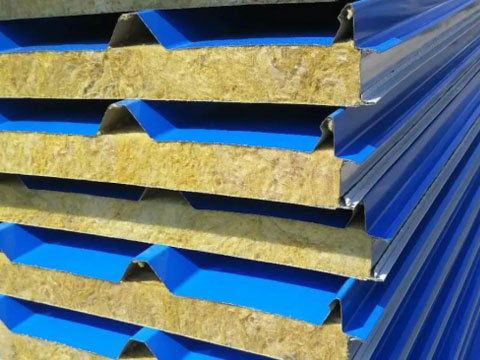

| Powder coating | Electrostatic spraying of resin powder → high-temperature curing | Corrosion-resistant, various colors, suitable for outdoor use | Powder particle size 30-80μm, curing temperature 180-220℃ |

Various Brushed Surfaces

There are many kinds of brushed stainless steel surfaces, and different surfaces have many details. If you have the surface you need, you can send us pictures and we can help you determine it. For more information about stainless steel, you can contact us.

Application of Different Finishes

| Finish type | Typical application scenarios | Performance advantages | Limitations |

| Mirror polishing | High-end building curtain walls, elevator cars, precision instruments | High reflectivity enhances the sense of luxury in space | Easily scratched, requires regular maintenance |

| Brushed finish | Home appliance panels, medical equipment, elevator buttons | Anti-fingerprint, strong wear resistance | Glossiness lower than mirror |

| Sandblasting | Modern furniture, outdoor sculptures, industrial equipment | Hide scratches, reduce reflection | Porous surface requires sealing |

| Embossed finish | Anti-slip pedals, art walls, acoustic panels | Enhance friction/sound absorption effect | High processing cost |

| Chemical coloring | Vintage decorations, solar collectors | Weather-resistant color layer, high heat absorption efficiency | Limited color selection |

| PVD coating | Luxury display cabinets, high-end door handles | Strong metallic texture, excellent corrosion resistance | High cost, film may fall off |

| Anti-fingerprint coating | Public handrails, touch panels | Easy to clean, reduce pollution residue | Coating may wear out |

| Antibacterial coating | Hospital equipment, food processing tables | Continuous antibacterial effect | Antibacterial performance needs to be tested regularly |

What are the Surface Treatment Methods of Stainless Steel?

Mechanical treatment

Polishing

- Finishing type: No.3, No.4, No.6, No.7, No.8 (mirror).

- Features: Smooth surface, high reflectivity, suitable for highly decorative occasions.

- Application scenarios: architectural decoration, home appliances, kitchenware, etc.

Sandblasting

- Finishing type: matte surface.

- Features: The surface is evenly rough and has good anti-slip effect.

- Application scenarios: building exterior walls, industrial equipment, etc.

Brushed

- Finishing type: HL surface.

- Features: The surface has fine lines and is matte.

- Application scenarios: elevator panels, home appliances, architectural decoration, etc.

Chemical treatment

Pickling

- Finish type: No.1, No.2D.

- Features: Rough surface, matte, remove oxide scale and rust.

- Application scenarios: industrial equipment, chemical equipment, etc.

Passivation

- Finish type: No.2B.

- Features: Smooth surface, enhanced corrosion resistance.

- Application scenarios: food processing equipment, medical equipment, etc.

Electrolytic polishing

- Finish type: No.8 (mirror).

- Features: No wear marks on the surface, high reflectivity.

- Application scenarios: high-precision parts, high-end decoration, etc.

Chemical treatment

Electroplating

- Finish type: colored stainless steel surface.

- Features: The surface is plated with other metals and has various colors.

- Application scenarios: decorative buildings, artworks, etc.

Anodizing

- Finish type: colored stainless steel surface.

- Features: An oxide film is formed on the surface with rich colors.

- Application scenarios: architectural decoration, electronic products, etc.

Heat treatment

Annealing

- Finish type: BA surface.

- Features: The surface is smooth, bright, and has high reflectivity.

- Application scenarios: home appliances, kitchen utensils, architectural decoration, etc.

Quenching

- Finish type: industrial surface.

- Features: High surface hardness and good wear resistance.

- Application scenarios: tools, molds, etc.

Coating treatment

Spraying

- Finish type: colored stainless steel surface.

- Features: various surface colors and good corrosion resistance.

- Application scenarios: outdoor equipment, architectural decoration, etc.

PVD/CVD

- Finish type: high gloss, high hardness surface.

- Features: wear-resistant, corrosion-resistant surface, rich colors.

- Application scenarios: high-end decoration, tools, etc.

Other treatments

Laser treatment

- Finish type: customized pattern surface.

- Features: high surface hardness and fine pattern.

- Application scenarios: high-precision parts, decorative products, etc.

Coloring treatment

- Finish type: colored stainless steel surface.

- Features: various surface colors and strong decorativeness.

- Application scenarios: architectural decoration, artwork, etc.

Recommendations for Choosing Different Finishes

1. Functionality first

- Corrosion resistance: pickling passivation, molybdenum-containing stainless steel (such as 316).

- Abrasion resistance: brushing, sandblasting, PVD coating.

- Hygiene: antibacterial coating, mirror (easy to clean).

2. Aesthetic needs

- Modern simplicity: sandblasting, brushing, black titanium PVD.

- Luxury style: mirror, rose gold PVD, etched pattern.

- Vintage style: chemical blackening, etched antique pattern.

3. Cost and maintenance

- Low cost: pickling passivation, sandblasting.

- Low maintenance: anti-fingerprint coating, powder coating.

- High cost: PVD coating, custom etching.

4. Environmental adaptation

- Marine/Chemical: pickling passivation + coating.

- High traffic public areas: anti-fingerprint coating + brushing.

- Medical/Food: antibacterial coating + mirror.

Conclusion

There are various ways to treat the surface of stainless steel in order to enhance its aesthetics, corrosion resistance, wear resistance and other functional properties. By combining different processes (such as mirror + embossing), a balance between decorativeness and functionality can be achieved to meet diverse needs.

Wanzhi Steel-China’s professional stainless steel supplier

Wanzhi Steel, as an ISO 2015:9001 certified company, has over 14 years of export experience, serving over 120 countries and regions. With years of experience and a complete supply chain, we can supply you with stainless steel of various types (coils, plates, wires, tubes, etc.), grades, specifications, and finishes. If you have a project that requires stainless steel, please contact us for details.