Table of Contents

- What Is Pvdf Coating

- PVDF Coating Performance and Characteristics

- Where PVDF Coating are Suitable

- PVDF Coating Colors

- What are the PVDF Finish Types

- PVDF vs HDP/SMP/PE

- Wanzhi Steel PVDF Products

What Is Pvdf Coating

PVDF coating is a semi-crystalline fluorine-containing polymer material, which is made by polymerization of polyvinylidene fluoride monomer (PVDF).

PVDF coatings are formed by mixing PVDF resin with other additives (such as pigments, solvents, additives, etc.), and then coated on the surface of the metal substrate, and then cured to form a thin film with protective and decorative functions.

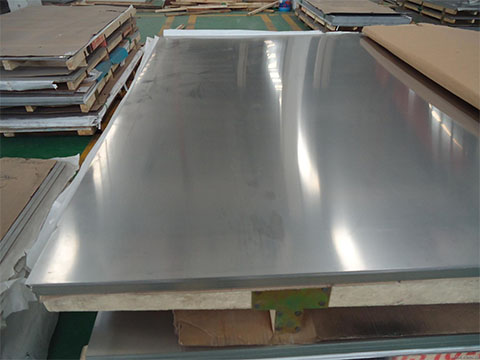

PVDF coatings are commonly applied to galvanized steel, galvalume steel, cold rolled steel, ZAM steel, stainless steel, aluminum/aluminum alloys, and so on.

PVDF Coating Performance and Characteristics

- Best weathering resistance: It is the best weathering resistant coating, which can resist the erosion of natural environment such as ultraviolet rays, high temperature, wind and rain for a long time, and is not easy to fade, chalking or cracking.

- Excellent corrosion resistance: with the chemical stability of fluorocarbon molecules, PVDF coatings are resistant to acid, alkali, salt and other chemical corrosion, applicable to highly corrosive environments.

- Highly decorative: it can be deployed with a variety of colors and textures, as well as matte and high-gloss effects, with good color retention and no fading in long-term use.

- Good performance of high and low temperature resistance: it can be used for a long time in the temperature range from – 40℃ to 150℃ without significant impact on the performance, and it can withstand high temperature of 200℃ for a short period of time.

- Self-cleaning: low surface energy, dust is easily washed away by rain, low maintenance cost.

Where PVDF Coating are Suitable

With superb weather resistance, chemical stability, self-cleaning and mechanical strength, PVDF coatings are widely used in areas with high demands for durability and appearance, mainly including:

- High weathering needs: long outdoor exposure time, strong UV rays (e.g. tropical areas, plateaus).

- Strong corrosive environment: chemical pollution, coastal area construction, marine engineering, salt spray, acid rain areas.

- Long life requirements: more than 20 years maintenance-free (such as landmark buildings, infrastructure).

- High-end decorative scenes: scenes requiring metallic luster, pearlescent effect or special texture.

PVDF Coating Colors

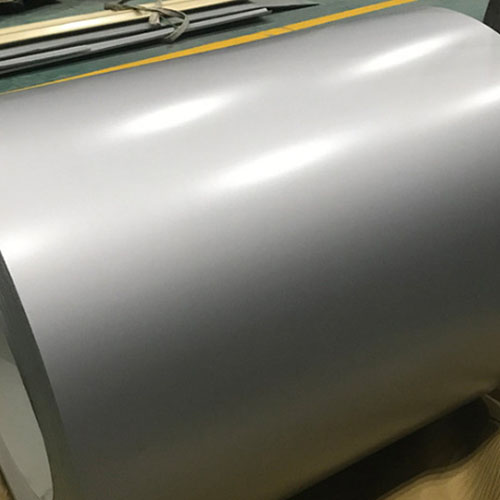

- Classic neutral colors: white (pure white, ivory), black (deep black, matte black, coal black), gray (light gray, medium gray, metallic gray).

- Metallic colors: silver, champagne gold, bronze, titanium gold and so on.

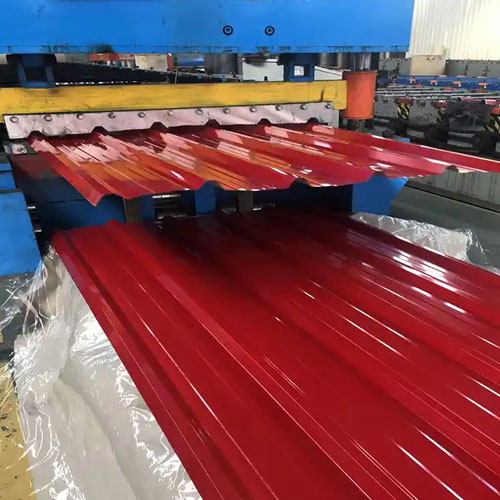

- Color system: red (Chinese red, burgundy, red), blue (dark blue, light blue, sky blue), green (dark green, grass green), yellow (lemon yellow, golden yellow), etc.

- Texture imitation color: imitation wood grain (dark brown, light walnut color), imitation stone grain (marble grain, granite grain).

Our PVDF coating colors are mainly based on RAL color cards, and can also be blended according to the samples provided by customers.

What are the PVDF Finish Types

High gloss, matte, frosted, crinkle, textured (wood, stone, brick) finishes, and some special finishes, such as anti-static finishes, self-cleaning finishes, etc.

PVDF Coating on Steel

Steel suitable for PVDF coating

GI steel, GL steel, cold-rolled steel, ZAM steel, stainless steel, etc.

Advantages of PVDF+steel

Excellent corrosion resistance and weather resistance; high decorativeness; economical, etc.

PVDF Coating on Aluminium

Aluminum suitable for PVDF coating

- Pure aluminum series (1xxx): 1050, 1060, 1100, etc.

- Aluminum-manganese alloy (3xxx): 3003, 3004, 3105, etc.

- Aluminum-magnesium alloy (5xxx): 5005, 5052, 5083, etc.

- Aluminum-magnesium-silicon alloy (6xxx): 6061, 6063, 6082, etc.

Advantages of PVDF+aluminum

Super corrosion resistance and weather resistance; stable color and no fading, strong decorativeness; easy to process and maintain.

PVDF vs HDP/SMP/PE

| Comparison items | PVDF | HDP | SMP | PE |

| Core ingredients | Polyvinylidene fluoride (fluorocarbon resin) | Modified polyester resin | Polyester + silicone modification | Standard polyester resin |

| Fluorine content | High (59% fluorine atoms) | None | None | None |

| Weather resistance | Excellent (25-30 years) | Excellent (15-20 years) | Medium (10-15 years) | General (5-10 years) |

| Chemical resistance | Resistant to strong acids, alkalis, and solvents | Weak acid and alkali resistance | Weak acid and alkali resistance | Poor |

| Temperature range | -40℃~150℃ (long-term use) | -20℃~100℃ | -20℃~100℃ | -20℃~80℃ (easy to deform at high temperature) |

| Mechanical properties | High hardness (2H+), strong wear resistance, excellent impact resistance | Medium hardness (1-2H), good wear resistance | Optimal flexibility | Low hardness (1H), average wear resistance |

| Self-cleaning | Excellent, dust is difficult to adhere to, rainwater self-cleans | Medium self-cleaning, regular maintenance required | Medium self-cleaning, slightly better than HDP | Easy to absorb dust, need frequent cleaning |

| Cost | Highest | High | Medium | lowest |

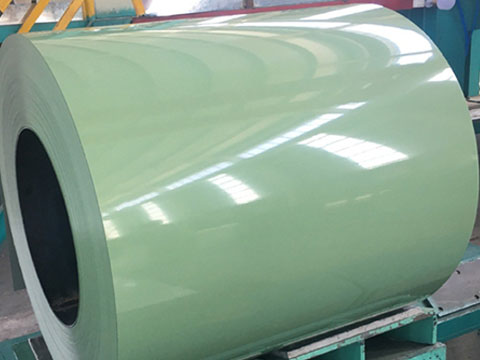

Wanzhi Steel PVDF Products

Wanzhi Steel has multiple color-coated metal coil production lines. All products are strictly tested. With rich experience in production and export, we can provide perfect solutions for your project. If your project requires color-coated metal coils, please contact us.