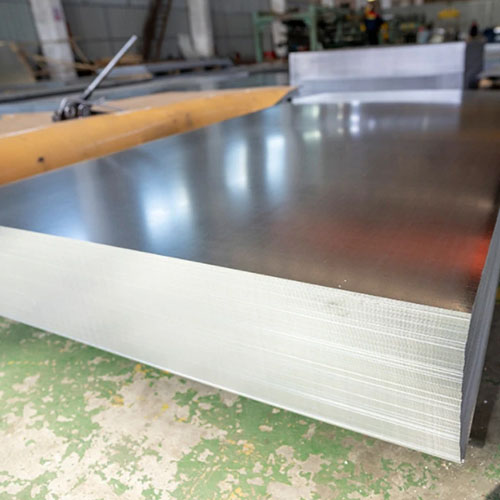

Zero Spangle Gi Sheet

Zero Spangle Gi Sheet has a smooth appearance, uniform zinc coating, and excellent corrosion resistance, and is widely used in various industries. We produce Zero Spangle Gi Sheet in various specifications and with a zinc coating amount of 30-275g/㎡.

Thickness: 0.12-4.0mm

Width: 30-1500mm or as your request

Length: According to your requirements

Material: DX51D, DX52D, DX53D, Q235, Q345, SGCC, etc.

tag: Galvanized steel

Ensure product quality and transportation

Wanzhi Steel is a professional manufacturer of galvanized steel in China, with ISO 9001:2015 certification. The factory is located in Shandong Province, with 2 hot-dip galvanizing production lines and a monthly production capacity of more than 10,000 tons, which can meet the production of bulk orders.

We also provide processing services, including slitting, cut-to-length, steel plate profiling, punching, etc. Among them, multiple roll forming machines can produce various types of galvanized corrugated sheets.Products are exported to 120 countries and regions, welcome to contact us for details.

Zero Spangle Gi Sheet Meaning

The spangle on galvanized steel is the crystal grains produced on the steel surface during the hot-dip galvanizing process. These crystal grains appear in the shape of snowflakes or hexagonal stars, which are spangles.Zero spangle means that there are no obvious spangles on the surface of galvanized steel.

Zero Spangle Gi Sheet Specifications

| Product Name | Zero Spangle Gi Sheet |

| Thickness(mm) | 0.12-5.0mm |

| Width(mm) | 30-1500mm or as your request |

| Length(mm) | According to your requirements |

| Material | DX51D, DX52D, DX53D, Q235, Q345, SGCC, etc. |

| Standard | GB, JIS, EN, etc. |

| MOQ | 10 Tons |

| Place of Origin | Boxing, Shandong |

| Quotation Method | EXW, FOB, CIF, etc. |

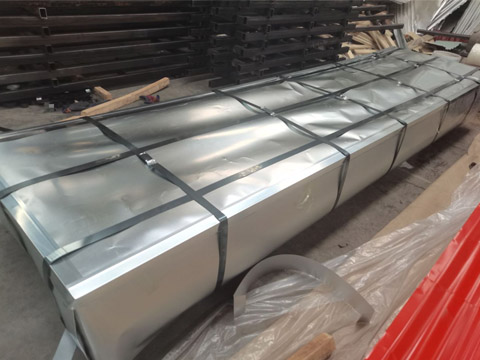

| Packaging | Standard export package or as per your requirements |

| Delivery Time | 15-25 working days after payment |

| Detection | Routine detection or Support third party inspection |

Zero Spangle Galvanized Steel Strips Production Video

Application of Zero Spangle Galvanized Sheet

The smooth surface of zero spangle galvanized sheet is conducive to painting and coating adhesion, which can ensure the surface quality and performance of the product. It is often used in the following scenarios:

- Automobile manufacturing industry: automobile outer covering and interior parts.

- High-end home appliance industry: such as the shell of high-end refrigerators, air conditioners, etc.

- Electronics industry: the shell and internal structural parts of electronic products.

- Medical device industry: strict requirements on the surface quality and hygiene of products, zero spangle galvanized sheet can meet its clean and smooth needs.

Zero Spangle vs Regular Spangle

Appearance Difference

- The surface of the galvanized sheet with zero spangle is relatively smooth and uniform, with a more simple beauty.

- The surface of the galvanized sheet with regular spangle presents a unique crystal pattern, just like snowflakes in nature, scattered and orderly, giving people a unique visual experience.

Performance Difference

- The galvanized sheet with zero spangle has high flatness, which is more conducive to subsequent processing and zinc layer adhesion, the zinc layer is more uniform, and the corrosion resistance is better.

- The galvanized sheet with regular spangle may affect the adhesion and uniformity of the coating in some cases due to its crystal pattern on the surface.

Application Difference

- Zero spangle galvanized sheet is particularly suitable for scenes with strict requirements on surface quality and appearance, such as automobile manufacturing, high-end home appliance industry, medical device industry, etc., because of its smooth and uniform appearance, uniform zinc layer and excellent anti-corrosion performance.

- Regular spangle galvanized sheet is suitable for scenes with low requirements for appearance decoration and more emphasis on cost and basic corrosion resistance.Ordinary mechanical parts, shelves, storage equipment, etc. manufactured by general industry, and some other large non-appearance building structures, such as supporting structures of factories and warehouses.

Price difference

- The production process of zero-brightness galvanized sheet often requires stricter process control, and the price will be slightly higher.

- The production process of conventional bright-piece galvanized sheet is relatively simple and the price is relatively low.

Gi Sheet Packaging

Case

Final Words

Wanzhi Steel is a famous galvanized steel manufacturer in China, with three galvanizing production lines, including 2 hot-dip galvanizing and 1 electro-galvanizing production line, we provide galvanized steel products with large spangle, regular spangle, small spangle and zero spangle.

Our Cases

Our galvanized products include:

- Galvanized Steel Coil

- Galvanized Steel Sheet

- Electro-galvanized Steel

- Galvanized Roof Sheet

- Pre-painted Galvanized Steel Coil

No matter what kind of spangle is on the surface of galvanized steel, it is widely used in various industries. If you are looking for a reliable Chinese galvanized steel manufacturer, Wanzhi Steel is your best choice. We strictly control product quality and provide the most competitive prices. You are always welcome to contact us.