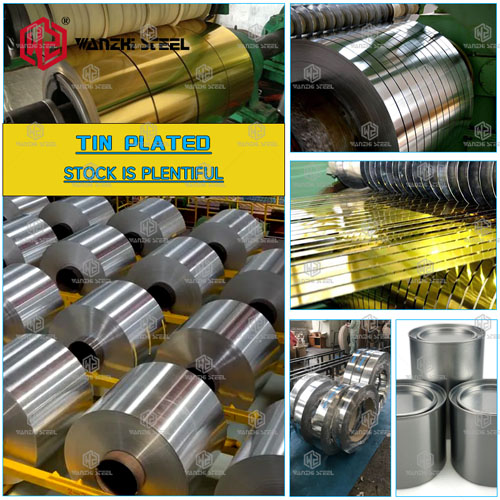

Tin Plated Steel

Wanzhi Steel is a high-quality tin plated steel supplier, providing you with high-quality tin plated steel products, the price is the factory wholesale price, and the price is more favorable for large-volume orders.

Thickness: 0.13-0.7mm

Width: 300-1500mm or as your request

Tin Coating: 1.0-5.6g/m2

Finish: Stone, Bright, Silver, Matt, gold lacquered

Ensure product quality and transportation

Tin-plated steel is a type of steel that has been tinned on the surface. The tin layer has anti-corrosion and sealing effects. The tinning process includes electroplating and hot-dip tinning.

Tin-plated steel has the characteristics of low cost, easy processing, corrosion resistance, non-toxicity, odorlessness, and beautiful appearance. It is widely used in food packaging, chemical, electrical, manufacturing and other fields.

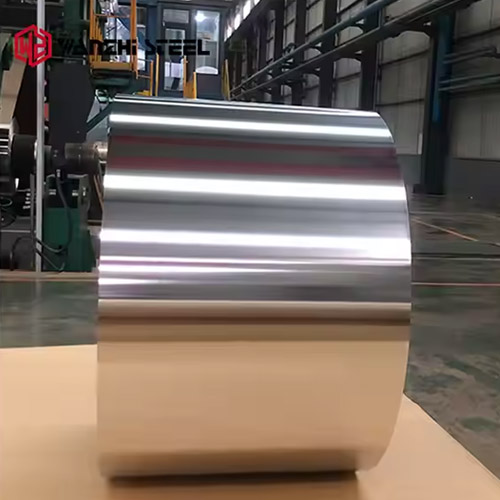

Tin Plated Steel Specifications

| Product Name | Tin plated Steel |

| Thickness(mm) | 0.13-0.7mm |

| Width(mm) | 300-1500mm or as your request |

| Material | SPCC, MR, Q195L, SPHC, etc. |

| Tin Coating | 1.0-5.6g/㎡ |

| Hardness | T1, T2, T3, T4, T5, DR8, DR9 |

| Coil Id | 508mm/610mm |

| Coil Weight | 1-5tons Or as your request |

| Finish | Stone, Bright, Silver, Matt, gold lacquered |

| MOQ | 25 Tons |

| Packaging | Standard export package or as per your requirements |

The thickness of tinplate used for cans is generally between 0.15 and 0.3 mm, and the most commonly used thicknesses are 0.2 mm, 0.23 mm, 0.25 mm, and 0.28 mm. The selection is based on the size of the can and the nature of the contents.

Advantages of tin plated steel

1. Strong anti-corrosion: The tin layer on the surface of tin-plated steel can effectively prevent the corrosive medium from contacting the steel plate, forming a protective barrier, thereby preventing the steel plate from rusting and corroding.

2. Easy to process: Tin-plated steel has good formability and processability, and is easy to process into various shapes and structures through stamping, stretching and other processes.

3. Good mechanical properties: Tin-plated steel has high strength, good rigidity, and is not easy to break, which can meet the requirements of mechanical properties of materials in different fields.

4. High temperature stability: Tin-plated steel has excellent heat resistance, performs well at high temperatures, and is not easy to rust and corrode.

5. Good weldability: Tin-plated steel is easy to weld and can be processed into products of various shapes and sizes.

6. Good appearance: The tin layer on the surface of tin-plated steel is flat, bright, and beautiful in appearance.

7. Environmental protection: Tin-plated steel can be recycled in most cases, which helps to reduce resource waste and environmental pollution.

Tin Plated Steel Applications

Food Field

- Canned food: canned fish, canned meat, canned vegetables, etc.

- Beverage containers: carbonated beverage cans, juice cans and beer cans, etc.

- Food molds: pie pan, baking pan, cookie cutters, egg tart molds, etc.

- Other food containers: biscuit boxes, candy cans, tea cans, milk powder cans, etc.

Chemical Field

- Chemical Containers: chemical tanks, aerosol cans, etc.

- Chemical Equipment: storage tanks, reactors, etc.

Electrical Field

Electronic Components, Cable Manufacturing, Electric Wire Connectors, etc.

Other Applications

Gift boxes, pencil cases, bottle caps, auto parts, building components, home appliance housings and internal components, raw materials for small hardware products, etc.

Passivation treatment of tin plated steel

Three chromium-free passivation methods

- Inorganic passivation: molybdate/phosphate passivation, tungstate passivation, rare earth metal salt passivation, silicate passivation, rock solution passivation containing zirconium and cobalt.

- Organic passivation: diaminotriazine and its derivatives passivation, acrylic resin passivation, tannic acid passivation, epoxy resin passivation.

- Compound passivation: phytic acid-phosphoric acid passivation, organic-molybdate passivation.

The role of passivation

- Because there are many gaps in the tin-plated layer, by passivating the tin-plated steel, a dense and non-corroded oxide layer can be formed on the metal surface, thereby improving the metal’s corrosion resistance, oxidation resistance, paint film adhesion and other properties.

- In addition, it can also improve the appearance, because tin plating passivation can make the metal surface smooth and uniform.

Packaging

Wanzhi Steel Group adopts standard export transportation packaging according to the packaging process requirements. According to our export experience, a 20-foot container can hold about 25 tons of steel coils. If it is a larger order, we generally recommend bulk carrier transportation because the transportation price is cheaper.

If you have packaging requirements, we will install your customized packaging.

Conclusion

Wanzhi Steel Group is a steel company with 13 years of export experience, serving more than 120 countries and regions. We have tin plated steel with competitive prices and premium quality, providing a variety of specifications, coating weights, and multiple surface treatments to meet all your needs.

Why choose us

- Strict quality inspection system to ensure the quality and specifications of tin plated steel products.

- We have a multilingual team to provide you with service 24 hours a day.

- Perfect service process: inquiry → quotation → contract signing → deposit payment → workshop production → balance payment → delivery