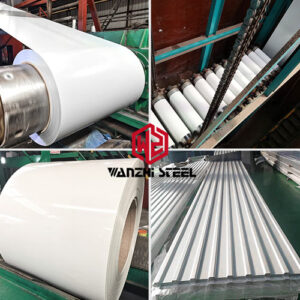

PVDF Coated Metal Coil

Wanzhi Steel can supply PVDF coated metal coil in a wide range of materials with complete specifications and excellent performance, especially for highly corrosive environments. Please feel free to contact us with any questions you may have.

Thickness: 0.11 – 2.0mm

Width: 20 – 1500mm

Substrate: Galvanized steel, Galvalume steel, Aluminium, etc

Ensure product quality and transportation

PVDF-coated metal coil is a high-performance pre-painted material featuring a polyvinylidene fluoride (PVDF) fluorocarbon resin coating cured onto the metal substrate surface via a high-temperature baking process. This coating system is recognized as the premier choice in architectural coatings, renowned for its exceptional durability and protective properties. It is widely used in applications demanding stringent requirements for material longevity and appearance retention

Specifications

| Product name | PVDF Coated Metal Coil |

| Thickness | 0.11 – 2.0mm |

| Width | 20 – 1500mm |

| Substrate | Galvanized steel, Galvalume steel, Aluminium, etc |

| Coating | Galvanized: Z30-Z275g/m², aluminum-zinc: AZ30-AZ150g/m² |

| Roll Weight | 3 – 5 tons |

| Roll Inner Diameter | 508/610mm |

| Conventional Color | Grass green, sea blue, white gray, wall gray, ivory white, etc. or customized according to needs |

| Material | SPCC, SPGC, SGCC, DX51D, DX52D,DX53D, S250GD,S350GD,S550GD,A653, etc. |

| Standard | ASTM,JIS,EN,GB |

| Processing Service | Flattening, slitting, rolling, profiling, punching, etc. |

| MOQ | 10 tons |

| Packaging | Standard export package or as per your requirements |

Our PVDF Coating Technology

- Thoroughly clean the metal substrate prior to coating; the substrate must be clean and free of contamination, with the chemical pretreatment film intact and undamaged;

- Maintain a highly clean coating environment, strictly controlling the cleanliness of the coating chamber to prevent impurities from affecting coating flatness;

- Ensure stable coating viscosity throughout the process to guarantee uniform coating thickness;

- Primers are selected from polyurethane or epoxy types to guarantee coating adhesion to the substrate;

- Filtration systems undergo regular inspection during coating, with clogged or damaged filters replaced promptly to prevent impurity contamination;

- During baking, precisely control panel temperature (PMT) to 249°C with a curing time set to 23 seconds;

- After baking, select either air cooling or water cooling based on production requirements to ensure stable coating formation.

Features of PVDF Coated Metal Coil

- Exceptional Stability: The fluorocarbon bond structure provides the coating with outstanding chemical stability, maintaining consistent performance over extended periods in acidic, alkaline, and polluted environments.

- Exceptional Durability: Withstands over 20 years of outdoor exposure while maintaining color integrity and gloss, featuring outstanding UV resistance.

- Superior Processability: Flexible and impact-resistant coating supports post-forming operations including embossing, bending, and cutting.

- Lightweight, High-Strength, and Eco-Friendly: Combines lightweight construction, high strength, and corrosion resistance without releasing harmful substances, aligning with green building standards.

- Fire-Resistant, Moisture-Proof & Composite Applications: Commonly used in systems like polyurethane-edged composite panels as surface or edging materials, enhancing overall fire resistance, thermal insulation, and structural strength.

- Easy & Efficient Installation: Lightweight material with excellent workability simplifies installation processes, shortening construction timelines while delivering both practicality and aesthetics.

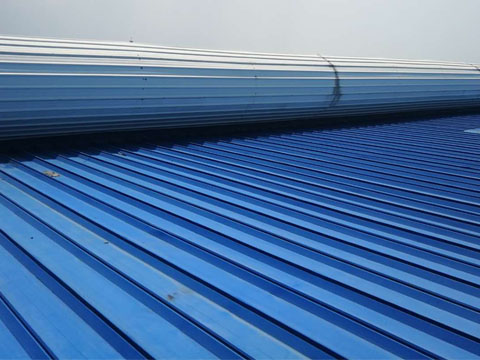

PVDF Coated Metal Coil Application

With outstanding corrosion resistance, UV resistance, lightweight aesthetics, and easy processing, PVDF-coated metal coil finds extensive applications:

- Buildings exposed to harsh environments long-term, such as stadiums, high-speed rail stations, power plants, coastal areas, and high-altitude regions;

- Exterior wall and roofing systems for public buildings and industrial facilities requiring high aesthetics and durability;

- Providing a new eco-friendly raw material that is weather-resistant, lightweight, and ready for direct processing for industries including shipbuilding, vehicle manufacturing, furniture, and electrical equipment.

Wanzhi PVDF Coated Steel Products

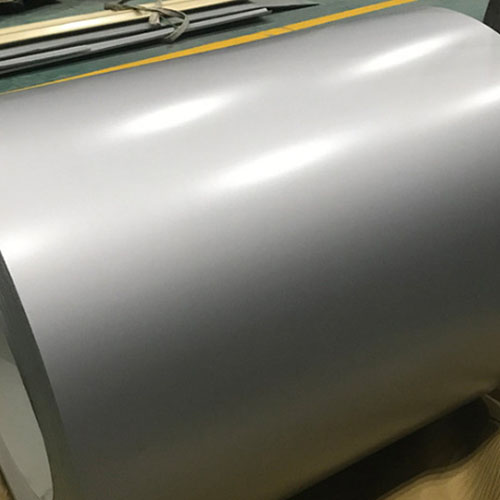

PVDF coated on galvanized steel coil(PPGI Coil)

It has dual anti-rust functions of galvanized layer and pvdf coating, and has excellent processability and high cost performance.

PVDF coated on galvalume steel coil (PPGL Coil)

It has stronger corrosion resistance, very long service life, and is resistant to high temperature and humidity.

PVDF coated on aluminum coil (PPAL Coil)

It is very light, very corrosion-resistant, and has good ductility.

Comparison and recommendations of three products

| Item | PVDF galvanized steel coil | PVDF Galvalume Steel Coil | PVDF Aluminum Coil |

| Corrosion Resistance | Medium (depends on the galvanized layer) | Excellent (self-healing of galvalume) | Excellent (aluminum base + coating) |

| Weight | Heavy (steel substrate) | Heavy (steel substrate) | Light (aluminum base) |

| Cost | Relatively low | High | High |

| Typical Applications | Chemical equipment, ordinary curtain wall | Extreme environment, high-end curtain wall | Extreme environment, super high-rise, artistic decoration |

Note: For coastal projects with limited budget, PVDF-coated galvanized steel + Z275 galvanized layer is also suitable for coastal high-corrosion environments.

Our Packaging

Why Choose Us

- Honest company: We are a factory with more than 14 years of export experience, ISO 9001:2015, CE certified, and have successfully exported to more than 120 countries and regions.

- Quality assurance: Products undergo strict quality inspections, including appearance, specifications, performance, etc., and support third-party inspections.

- Sufficient inventory: We have multiple large warehouses with a storage area of more than 56,000 square meters, a large amount of inventory in stock, and a full range of specifications and grades.

Wanzhi Steel has 3 color-coated steel production lines, hundreds of profiling equipment, 2 longitudinal shears, and 4 cutting equipment. We can provide you with a variety of materials and types of color-coated coil products. If you have any needs for color-coated metal products, please feel free to contact us.