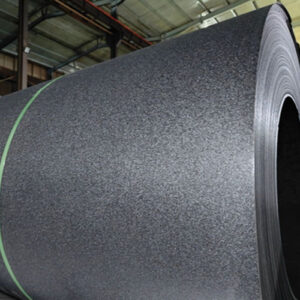

Prepainted aluminum coil

The pre-painted aluminum coils produced by Wanzhi Steel use PE and PVDF as the main surface coatings. The appearance patterns can be customized. Common patterns include wood grain, brick grain, stone grain, etc. The colors are based on the RAL color card and can be customized.

Width: 600mm-1500mm

Thickness: 0.2mm-4.00mm

Coating: PE,PVDF,wood grain, printing, etc.

Material: AL1100, AL3003, AL3004, AL3105, AL5005, AL5052, etc.

Place of Origin: Shandong, China

Ensure product quality and transportation

Pre-painted aluminum coils are corrosion-resistant, lightweight, and beautiful in appearance, and are widely used in the field of building decoration. The pre-painted aluminum coils produced by Wanzhi Steel are of guaranteed quality and reasonable price. The surface coating color can be guaranteed not to fade for at least 30 years, and the appearance can be customized.

Prepainted Aluminum Coil Specifications

| Product name | Prepainted aluminum coil |

| Width | 600mm-1500mm |

| Thickness | 0.2mm-4.00mm |

| Length | As per your requirement |

| Coating thickness | Top:15-30um,Back:5-10um |

| Material | AL1100, AL3003, AL3004, AL3105, AL5005, AL5052, etc. |

| Coating | PE,PVDF,wood grain, printing, etc. |

| Impact resistance | 50kg/cm |

| Glossiness | 10-90% |

| Coating hardness | >2H |

| Package | Export Standard Seaworthy Packing |

| Transportation | Container、Bulk Ship、Train Or as your request |

Wanzhi pre-painted aluminum coil production

Features of pre-painted aluminum coils

1. Light weight

Compared with steel, aluminum has a lower density, which is about 7.85 g/cm³, while aluminum has a density of 2.7g/cm³. Under the same parameters such as length, width, and thickness, the weight of aluminum coils will be much lighter, which will facilitate transportation and subsequent installation.

2. Corrosion resistance

Aluminum coils themselves are corrosion-resistant and are not easy to rust after long-term use in humid and acidic environments. The surface of color-coated aluminum coils has another layer of paint coating, which makes pre-painted aluminum coils more corrosion-resistant.

3. Strong decorativeness

Wanzhi pre-painted aluminum coils have a variety of color options and can be customized according to your needs; in addition to the color selection, the appearance can also choose the pattern, such as wood grain, brick grain, stone grain, etc. The pattern can be customized, natural and beautiful, and has strong decorativeness.

4. Strong weather resistance

Wanzhi Steel uses high-quality raw materials for the production of pre-painted steel coils, and adopts advanced composite technology to manufacture. The products produced have good technicality and high folding resistance.

In different wind pressure, temperature, humidity and other environments, it can be used for a long time without bending, deformation and expansion.

5. Color stability

The surface paint of pre-painted aluminum coil is baked at high temperature, with high color gloss and long-lasting color. Generally, the color can be maintained for more than 20 years.

6. Environmental protection

The recycling value of aluminum coil is high and it can reduce resource waste. Color-coated aluminum coil does not contain harmful substances and will not release toxic gases in a corrosive environment, which meets environmental protection requirements.

Application of pre-painted aluminum coil

Pre-painted aluminum coil is corrosion-resistant, high-gloss, rich in color, and can meet personalized design. Whether it is residential or large-scale buildings, color-coated aluminum coils are widely used.

1. Construction field

Pre-painted aluminum coils are often used in roof corrugated panels, ceilings, blinds, curtain wall panels, rolling doors, garage doors, billboards, gutters, downspouts, etc. in the construction field.

2. Home appliance field

In the home appliance field, PPAL is used in computer cases, refrigerator/air conditioner/washing machine panels, air conditioner ducts, solar reflectors, lamps, etc.

3. Automotive field

Pre-painted aluminum coils are used in automotive parts and structures, carriages and other parts.

FAQ about pre-painted aluminum coils

1. Which is better, pre-painted aluminum coils or pre-painted galvanized coils?

The service life of pre-painted aluminum coils is 25-40 years, which is longer than PPGI steel, because it is lighter and easier to install. However, the price of pre-painted aluminum coils is higher. Both have their advantages and disadvantages, mainly depending on your budget and application environment.

2. How to identify the quality of pre-painted aluminum coils?

The most direct way to judge the quality of pre-painted aluminum coils is to judge by appearance. There is no or no obvious indentation, imprint, bumps, etc. on the surface, no missing coating, no damage to the coating, no ripples, bulges, scratches, abrasions, etc.

3. Can pre-painted aluminum coils be used for food packaging?

Yes, pre-painted aluminum coils can be used for food packaging, because aluminum coils can resist foods with high pH and salinity. In addition, aluminum coils have sealing and heat insulation properties, which can ensure the quality of food. 8000 series aluminum coils are often used for food packaging.

4. Which coating to choose between PE and PVDF?

Choosing which paint should consider your application environment. PE can resist UV rays. If it is used indoors or on billboards, PE paint can be used. PVDF has strong weather resistance and is more suitable for outdoor applications.

You may be interested: PPGL | Prepainted Steel Sheets | ppgi coil