Perforated Sheet Metal

The materials of perforated metal sheets include stainless steel, galvanized steel, color-coated galvanized steel, aluminum, etc. Wanzhi Group provides you with perforated metal sheets of different materials, various sizes, hole types and surface treatments.

Thickness: 0.2-10.00MM

Width: 600-2000mm

Length: 1200-6000mm Or as your request

Hole Diamete: 0.5-20mm Or as your request

Place of Origin: Shandong, China

Ensure product quality and transportation

Perforated metal sheets are formed by mechanical or stamping holes. They can absorb sound, reduce noise, provide ventilation and air permeability, and have decorative effects. They are widely used in daily life. Wanzhi perforated metal sheets can meet your needs for ventilation and appearance design, and ensure the accuracy and durability of the products during production. Wanzhi is a reliable choice for your commercial projects.

Perforated Metal Sheet Specifications

| Product Name | Perforated Sheet Metal |

| Material | Galvanized steel,Aluminum,Stainless steel,Color coated steel,Cold/hot rolled steel, etc. |

| Thickness | 0.2-10.00MM |

| Width | 600-2000mm |

| Length | 1200-6000mm Or as your request |

| Hole Diameter | 0.5-20mm Or as your request |

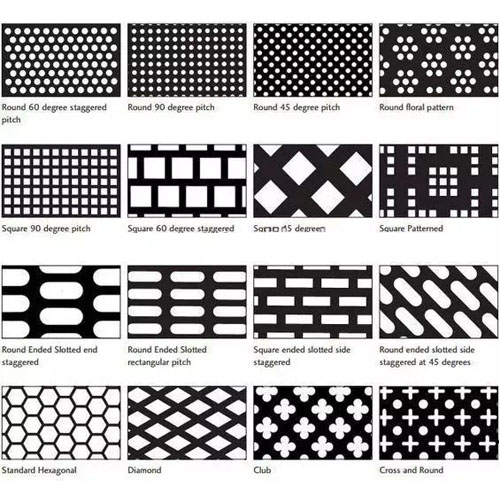

| Hole type | Round holes, square holes, rectangular holes,cross hole,elliptical holes, hexagonal holes, special pattern holes. |

| MOQ | 10 tons |

| Packing | Standard export package |

Types of Metal Perforated Plate

- Circular Hole Perforated Plate: The most commonly used hole pattern, with a variety of arrangements, suitable for a variety of screening, filtration, and decorative applications.

- Square Hole Perforated Plate: Features a large aperture ratio and high screening efficiency, commonly used in grain screening and ore screening.

- Special Shaped Hole Perforated Plate: Customizable hole patterns such as hexagonal, diamond, and oblong can be created to meet specific needs.

Perforated metal sheet performance

- Sound absorption and noise reduction: Sound absorption and noise reduction is one of the main properties of perforated metal sheets. Perforated metal sheets can absorb and reflect sound and reduce noise from the outside.

- Strong air permeability and ventilation: The holes in perforated metal sheets can increase air circulation and make the room well ventilated.

- Beautiful and practical: The perforated steel sheets have various hole types and can present different patterns. The surface can also be sprayed or painted to meet the requirements of different buildings for appearance, making the building more innovative and beautiful.

- Filtration: Perforated metal sheets have a filtering effect. They can filter dust and impurities in the air and keep the indoor air fresh while ensuring ventilation.

- Other properties: Perforated steel sheets also have high strength and durability. Galvanized steel, stainless steel, and aluminum perforated metal sheets are also highly resistant to corrosion.

Perforated metal sheet application

- Architectural Decoration: Used in building exterior walls, ceilings, partitions, railings, and other applications, combining aesthetics with functionality.

- Industrial Filtration: Perforated metal sheet is used in filtration, screening, and separation processes in the petroleum, chemical, and food industries.

- Sound Absorption and Sound Insulation: Used in venues requiring acoustic control, such as concert halls, theaters, and conference rooms.

- Mechanical Equipment: Used in various mechanical equipment as protective covers, ventilation panels, platforms, and walkways.

- Other Applications: Perforated metal sheet offers decorative and durable properties and can be used in office and bedroom furniture, as well as in decorative objects of various shapes.

FAQ abot Perforated metal sheet

What factors affect the aperture size of perforated metal plates?

1. Affected by the thickness of the perforated steel plate, the thicker the perforated steel plate, the larger the aperture.

2. Affected by different materials, the aperture range of perforated steel plates of different materials is also different. The aperture range of stainless steel is between 0.8mm-10mm, and the aperture range of steel perforated steel plates is relatively wide, between 0.5mm-100mm.

3. The aperture size of perforated steel plates is also affected by the shape of the hole pattern and the arrangement of the hole pattern.

How to choose perforated metal plates

When choosing perforated steel plates, four factors should be considered: application scenario, aperture, thickness of metal plate, and cost.

If the application scenario requires the metal plate to be corrosion-resistant, you can choose stainless steel perforated plates, galvanized perforated plates, color-coated galvanized perforated steel plates, etc.

There are many types and sizes of apertures of perforated metal plates. Choose according to your own purpose of use. Wanzhi Steel can also customize according to needs.

The thickness of perforated metal plates is different and the application scenarios are also different.When choosing a perforated steel plate, you should communicate the thickness of the perforated steel plate.

In terms of cost, the price will be different depending on the material of the perforated steel plate you choose. Aluminum and stainless steel are more expensive, color-coated galvanized and galvanized steel are moderately priced, and hot-rolled steel is the cheapest.

Does the hole size affect the performance of perforated metal plates?

The hole size will have a certain impact on the performance of perforated steel plates, mainly affecting the performance of perforated steel plates including load-bearing capacity, anti-slip performance, drainage performance and sound absorption capacity.

Does the hole size affect the price of perforated metal plates?

The hole size does have a certain impact on the price of perforated steel plates. When other parameters are the same, the price of perforated steel plates with small hole diameters will be more expensive, because the production of perforated steel plates with small hole diameters requires higher precision requirements and complex molds, and the production cost will increase, so perforated steel plates with small hole diameters will be more expensive.

Why Choose Wanzhi Steel?

- We utilize advanced production processes and a strict quality control system to ensure product performance.

- We have a complete production line and specialized processing equipment, ensuring accurate and uniform apertures.

- We are ISO 9001, ISO 14001, and other certifications, and export to over 100 countries.

Wanzhi Steel offers perforated metal sheeting including:

- Galvanized steel perforated sheeting

- PPGI perforated sheeting

- PPGL perforated sheeting

If you are interested in perforated metal sheeting, please feel free to contact us.

You may be interested: Galvanized Steel Coil | PPGI Coil | Woodgrain Metal Panels