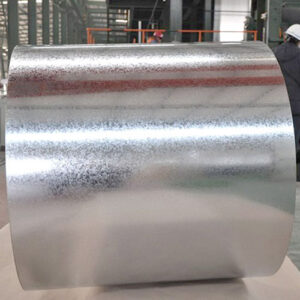

DX51D Galvanized Corrugated Steel Sheet

DX51D galvanized corrugated sheet boasts strong corrosion resistance, high strength, and relatively low cost, making it a preferred choice for customers across multiple sectors including construction, agriculture, and industry.

- Thickness: 0.3mm, 0.4mm, 0.45mm, 0.5mm, 0.6mm, 0.8mm, 1.0mm

- Effective Width: 750mm – 1200mm

- Sheet Length: ≤12m

Ensure product quality and transportation

DX51D galvanized corrugated sheet is manufactured using DX51D low-carbon steel as the base material. After undergoing hot-dip galvanization, it is processed into a corrugated metal sheet through a roll forming process.

Available Specifications

| Product Name | DX51D Galvanized Corrugated Steel Sheet |

| Thickness | 0.3mm, 0.4mm, 0.45mm, 0.5mm, 0.6mm, 0.8mm, 1.0mm |

| Effective Width | 750mm – 1200mm |

| Sheet Length | ≤12m |

| Coating | Z30 – Z275g/㎡ |

| Material Grade | DX51D |

| Yield Strength | 140 MPa – 300 MPa |

| Tensile Strength | 270 MPa – 500 MPa |

| Elongation After Fracture (A80) | ≥ 22% |

| Chemical Composition | C≤0.18%, Si≤0.50%, Mn≤1.20% |

| Standards | EN 10346, GB/T 2518, ASTM A653 / A653M |

| MOQ | 10 tons |

| Packaging | Standard export packaging (plastic film, moisture-proof paper, and galvanized iron sheet) |

Production Video

Why DX51D is Ideal as the Base Material for Galvanized Corrugated Sheets

- DX51D maintains excellent ductility while retaining strength, making it suitable for deep processing like roll forming.

- The “ferritic” phase of DX51D prevents cracking during roll forming.

- While DX51D’s strength is not the highest, it sufficiently withstands wind/snow loads and offers cost advantages.

Typical Applications

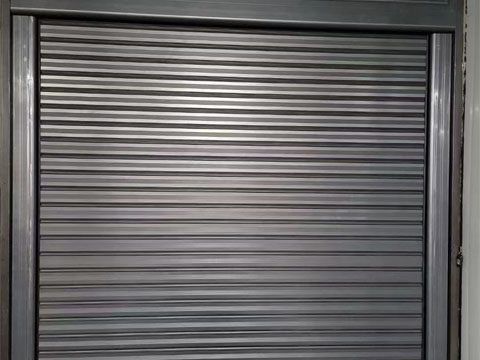

- Widely used as roofing tiles, exterior wall cladding, and partition panels in industrial plants, warehouses, rural self-built homes, and temporary structures.

- Serves as roofing and sidewall material for greenhouse structures, and can also be employed in constructing grain silos, livestock enclosures, and poultry farm fencing.

- Serves as garage doors, equipment enclosures, workshop partitions, and shelving baffles for material storage.

- Also suitable for interior partitions or decorative walls; or as roofing and exterior wall materials for bus shelters and guard booths.

Why Choose Us?

Our Advantages

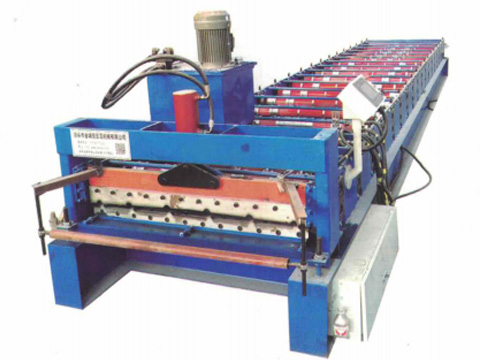

- We operate production lines for galvanized steel coil raw materials and possess specialized roll forming equipment, enabling rapid production of high-quality galvanized corrugated steel sheets.

- Our fleet of over 100 forming machines enables production of diverse corrugated steel profiles.

- Our in-house testing center rigorously inspects both raw materials and finished products to ensure quality.

- With over 14 years of manufacturing and export experience, we have successfully exported to over 100 countries and gained numerous loyal customers.

Our Factory & Equipment

Our diverse range of roll forming equipment enables production of various corrugated steel products. Should you require roll forming machinery for roof panels, we can supply directly from the source manufacturer at competitive prices.

We Supply DX51D Products

- DX51D Galvanized Steel

- DX51D Galvalume Steel

- DX51D PPGI Coil

- DX51D PPGL Coil

- DX51D Printed Steel Coil

Our Certifications

As a specialized manufacturer of galvanized steel products, we hold ISO 9001, ISO 14001, and CE certifications.

If you are interested in our DX51D galvanized corrugated steel sheets or wish to place an order, please contact us anytime. We guarantee high-quality products and exceptional pre-sales and after-sales service to ensure a worry-free purchasing experience.