DC03 Cold Rolled Steel

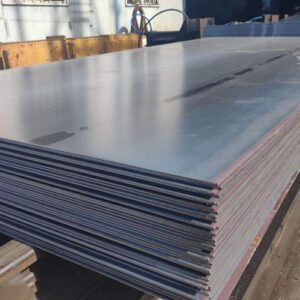

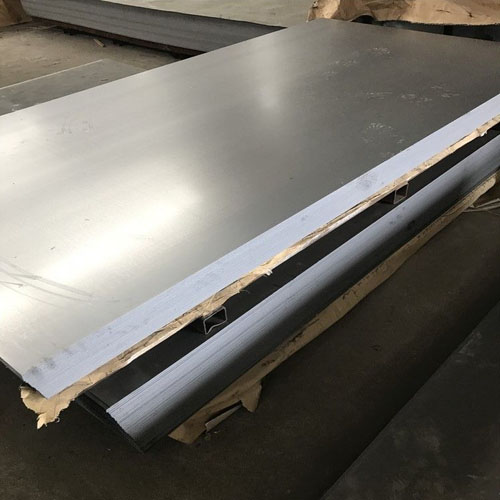

DC03 cold-rolled steel has excellent stamping performance and is widely used in the automotive, electrical appliance, and electronics industries. We supply DC03 cold-rolled steel products including coils, plates, and strip coils.

Ensure product quality and transportation

DC03 steel is a commercial-grade low-carbon steel defined in the European standard EN 10130. The “DC” in its designation stands for “deep drawing,” explicitly indicating its core characteristic of being primarily used for deep drawing applications.

Specifications

| Product Name | DC03 Cold Rolled Steel |

| Thickness | 0.15mm – 3.0mm |

| Width | 600mm – 1500mm or produced according to customer requirements |

| Length | 2000mm, 2500mm or multiples thereof |

| Type | Coil, Sheet, Strip |

| Standard | EN10130 |

| Processing Services | Slitting, length cutting, stamping, embossing, etc. |

| Surface Treatment | Pre-painted, hot-dip galvanized, electro-galvanized, powder coated, etc. |

| Inner Diameter of Steel Coil | 508mm or 610mm |

| Weight of Single Coil | 3 – 10 tons |

| Delivery | Production time varies, typically 7-30 working days, depending on quantity. |

| MOQ | 25 tons |

| Packaging | Standard export packaging (plastic film, moisture-proof paper, and galvanized iron sheet) |

DC03 Steel Chemical Composition

| Ingredients | C | P | S | Mn | Al |

| Content (%) | ≤0.1 | ≤0.035 | ≤0.035 | ≤0.45 | ≥ 0.020% |

Mechanical Properties

| Mechanical Properties | Yield Strength | Tensile Strength | Elongation after Fracture (A80) | Hardness (HRB) |

| Numerical values | 140 MPa – 240 MPa | 270 MPa – 370 MPa | ≥34% | 65-85 |

DC03 Cold-Rolled Steel Coil Advantages

- Superior Deep-Drawing Performance: Low carbon content + uniform grain structure enables withstanding severe tensile and deep-drawing deformation without cracking or distortion.

- High Surface Quality: Cold-rolling process yields a smooth, scale-free surface, facilitating subsequent operations like electrogalvanizing, hot-dip galvanizing, and pre-painting.

- Good ductility and toughness: High elongation allows significant plastic deformation before fracture, enabling complex bending, flanging, and forming operations.

Applications of DC03 Cold-Rolled Steel

- Automotive Industry: Body panels (doors, hoods), fuel tanks, mufflers, clutch plates, seat frames, and other internal structural components.

- Home Appliances: Outer casings and internal components for refrigerators, washing machines, air conditioners; microwave oven panels; water heater liners.

- Construction and Home Furnishings: Metal furniture, filing cabinets, lamp housings, decorative components, ceiling panels, etc.

- General Hardware and Stamped Parts: Complex containers requiring deep drawing and stretching (e.g., filter housings, food containers, metal cans), server cabinets, computer cases, hardware stampings, bent parts.

What Products Can Be Processed from DC03 Cold Rolled Steel

1. HOT-DIP GALVANIZED STEEL COIL

- Process: After cleaning and annealing DC03 cold-rolled steel coils, they are immersed in molten zinc for galvanization, followed by cooling and solidification.

- Features: Exhibits various zinc flower structures on the surface, offering strong corrosion resistance and excellent workability.

2.ROGALVANIZED STEEL COILS

- Process: Produced using DC03 cold-rolled steel coils as the substrate, applying pure zinc uniformly to the surface via electrolysis.

- Features: Uniform, fine coating with a smooth surface and moderate corrosion resistance.

3. GALVALUME STEEL COIL

- Process: The coating on DC03 cold-rolled steel coil contains 55% aluminum, 43.5% zinc, and 1.5% silicon.

- Features: Superior corrosion resistance compared to hot-dip galvanized steel, excellent high-temperature performance, and outstanding heat reflectivity.

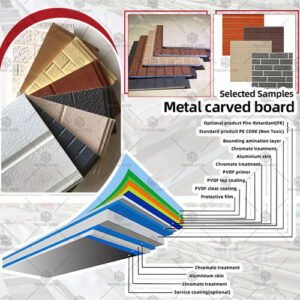

4. COLOR-COATED STEEL COIL

- Process: Using DC03 cold-rolled coil, DC03 GI coil/GL coil as substrate, undergoes surface pretreatment followed by continuous application of multiple layers of organic coating on both sides, then baked for curing.

- Features: Exceptional corrosion resistance combined with outstanding decorative properties.

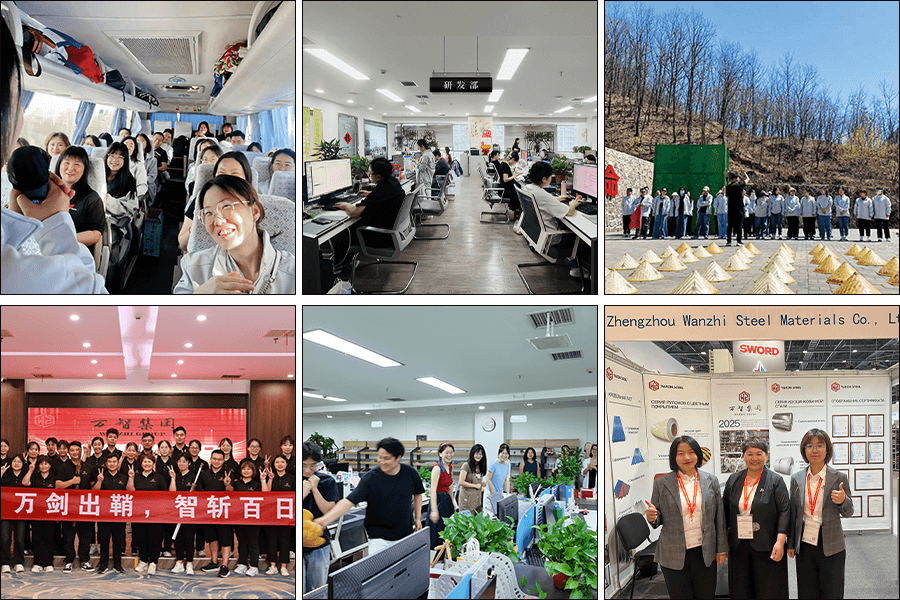

We supply all the above products processed from DC03 cold-rolled steel coils, which are our key offerings. Our factory is located in Shandong Province, China. We welcome you to visit our facility.

Why Choose Us?

Wanzhi Steel is China’s leading supplier of cold-rolled steel coils, offering various grades. The company holds multiple certifications including ISO 9001 and ISO 14001, and is recognized as a trustworthy supplier in China. We have successfully exported to over 100 countries. For any cold-rolled steel requirements, please contact us anytime.

Our Team

Our Clients