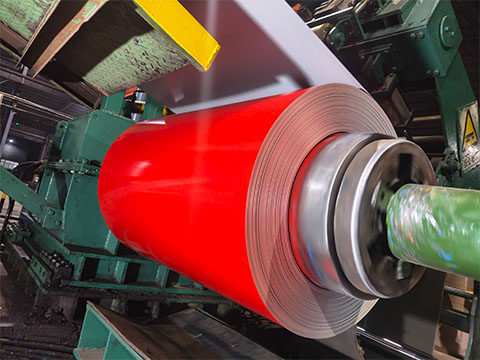

Cold Rolled Coils

WANZHI STEEL is a manufacturer of cold rolled steel in different specifications and grades, with an annual production capacity of about 200,000 tons and a stock of commonly used cold rolled steel.

Factory address: Shandong, China

Grade: Q195-Q235, SPCC, SPCD, SPCE, ST12-15; DC01-06, etc.

Thickness: 0.5- 3.0mm or as required

Width: 600 – 1500mm or as required

Transportation:By sea or Land transportation

Ensure product quality and transportation

Cold Rolled Steel Coil (CRC) is a steel produced by cold rolling on the basis of hot rolled steel, first rolled at room temperature and then rolled again at a temperature below its crystallization temperature, the cold rolled steel coils produced under this process are accurate in dimensions, beautiful in appearance and have good mechanical properties.

Wanzhi Steel has a wide range of Cold Rolled Steel Coil grades, to know more about Cold Rolled Steel Coil grades, please contact us.

Cold rolled coils parameters

| Item | Cold Rolled Steel Coil |

| Thickness | 0.5 -3mm |

| Width | 600 -1500mm |

| Grade | Q195, Q235, SPCC, SPCD, SPCE, DC01, DC03, DC04, DC05, DC06, ASTM A1008 CS Type B, C |

| Standards | GB, JIS, EN, ASTM |

| Coil Inner Diameter | 508mm (20”) or 610mm (24”) |

| Coil Weight | 5-13.5 tons or as required |

| Hardness | Softy, Halfhard, Hardquality |

| Mechanical Properties | Yield strength 235-355MPa; Tensile strength: 370-590MPa; Elongation ≥18% |

| Surface | Coating, spraying, embossing, electroplating, etc. |

| Delivery Condition | Annealed and Non-annealed |

| Delivery Time | 7-30 days (mainly depending on the order quantity) |

| Processing Service | Bending, Cutting, Slitting, Punching, etc. |

| MOQ | 25 TONS |

| Package | Standard Export Package |

Wanzhi CRC production video

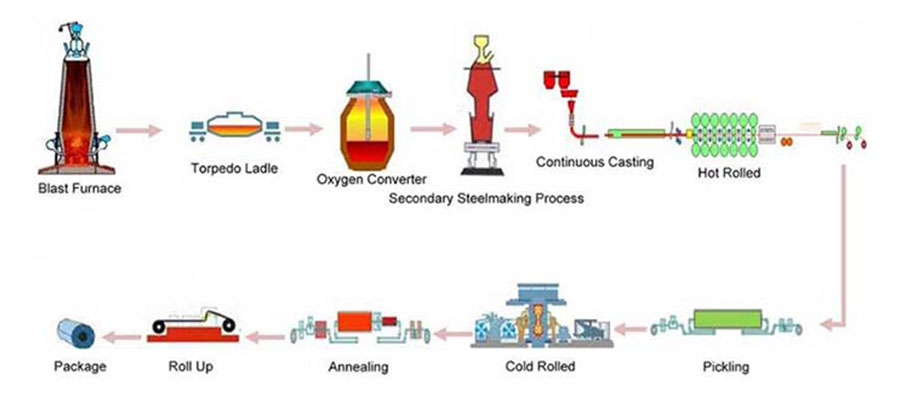

Cold rolled steel production process

Raw material (hot rolled steel) → raw material pickling → cold rolling → degreasing → annealing → coiling → packaging, the following cold rolled steel production process is described in detail:

- Pickling: hot rolled coils through the pickling line, the use of hydrochloric acid solution to remove the surface oxide skin. Through the pickling process, less surface defects are left behind.

- Cold Rolling: pickled coils are rolled to the specified thickness in a cold rolling mill.

- Annealing: through electrolytic cleaning to remove lubricants and contaminants, the coil will be continuous annealing process. The purpose is to manufacture steel with high tensile strength.

- Coiling and Packaging: annealed cold rolled coils are transported to the coiling equipment for coiling, followed by inspection and packaging.

Cold rolled steel coil characteristics

- high strength: cold rolled steel as far as physical properties are concerned, cold rolled steel is stronger, the strength is 20% higher than hot rolled steel.

- smooth surface: due to the cold rolled steel surface is not easy to oxidize, cold rolled steel surface shows a very good finish, and easier to paint.

- More accurate dimensions: Cold rolled steel has higher accuracy in longitudinal and transverse dimensions due to the characteristics of the production process.

Cold rolled steel coil applications

In the automotive industry, cold-rolled steel coil, due to its high dimensional accuracy, excellent wear resistance, and strong impact resistance, is commonly used in the following automotive components:

- Automotive body panels and doors;

- Car seats and mailboxes;

- Chassis components and brackets.

Due to its exceptionally smooth, aesthetically pleasing surface and high strength, cold-rolled steel coil is ideal for products requiring a high level of aesthetic appeal, such as:

- Home appliance panels like refrigerators and washing machines;

- Computer cases and office filing cabinets;

- Metal furniture panels and supports.

Cold-rolled steel coils, characterized by their high surface finish and strong coating adhesion, are commonly used as raw materials for metal-coated steel coils, such as:

- Hot-dip galvanized steel coil: Cold-rolled coils undergo cleaning and annealing before being immersed in a zinc bath to produce hot-dip galvanized steel coils.

- Electrogalvanized steel coil: Cold-rolled coils undergo electrogalvanization, commonly used in applications requiring high surface quality.

- Pre-painted steel coils: Cold-rolled coils serve as the standard raw material for producing color-coated steel coils (PPGI/PPGL).

Cold-rolled steel weight calculation

Cold rolled steel sheet weight calculation formula

Weight = thickness (mm) × length (m) × width (m) × 7.85 (g/cm³)

- Thickness: The thickness of the cold-rolled steel sheet, in millimeters (mm).

- Length: The length of the cold-rolled steel sheet, in meters (m).

- Width: The width of the cold-rolled steel sheet, in meters (m).

- 7.85: The density of the cold-rolled steel sheet (g/cm³).

theoretical weight table

| Thickness/mm | Theoretical weight /(kg/m²) | Thickness/mm | Theoretical weight /(kg/m²) | Thickness/mm | Theoretical weight /(kg/m²) |

| 0.2 | 1.57 | 0.9 | 7.065 | 2.5 | 19.625 |

| 0.25 | 1.936 | 1 | 7.85 | 2.8 | 21.98 |

| 0.3 | 2.355 | 1.1 | 8.635 | 3 | 23. 550 |

| 0.35 | 2.748 | 1.2 | 9.42 | 3.2 | 25.12 |

| 0. 40 | 3.14 | 1.3 | 10.205 | 3.5 | 27. 475 |

| 0.45 | 3.533 | 1.4 | 10.99 | 3.8 | 29.83 |

| 0.55 | 4.318 | 1.5 | 11.775 | 3.9 | 30.615 |

| 0.6 | 4.71 | 1.6 | 12.56 | 4 | 31. 400 |

| 0.65 | 5.103 | 1.7 | 13.345 | 4.2 | 32.97 |

| 0.7 | 5.495 | 1.8 | 14.13 | 4.5 | 35. 325 |

| 0.75 | 5.888 | 2 | 15.7 | 4.8 | 37.68 |

| 0.8 | 6.28 | 2.2 | 17.27 | 5 | 39.25 |

Our CRC Recent case

Iranian customers purchased 500 tons of cold-rolled steel coils

FAQ about CRC

Q1: What are the differences between SPCC, DC01, and DC04? Which one should I choose?

A: The main difference lies in their processing grades: SPCC/DC01 (commercial grade) is suitable for general bending and shallow stamping, offering cost-effectiveness; DC03 (stamping grade) is suitable for conventional stamping forming; DC04/SPCE (deep-drawing grade) is suitable for complex deep-drawn parts (e.g., fuel tanks).

Q2: Are cold-rolled steel coils prone to rusting?

A: Cold-rolled steel coils are susceptible to rusting in humid, outdoor environments. Storage requires dry, ventilated indoor warehouses. For outdoor applications, galvanized steel coils can extend service life.

Q3: Do you support exporting products? What shipping methods are available?

A: Our products are exported globally. Shipping methods include ocean freight and land transport. Land transport is typically used for countries close to China, such as Mongolia and Kazakhstan.

Q5: How can product quality be verified?

A: We provide free samples for testing (shipping costs apply). Additionally, our products come with detailed specifications including dimensions, hardness, tensile strength, and other metrics. We also welcome clients to visit our factory for on-site inspections.

Our packaging

Why Choose Wanzhi Steel

- Capacity Assurance: Sufficient production capacity (200,000 tons) with ISO 9001, ISO 14001, and CE certifications.

- High-Quality Products: Comprehensive quality control system with rigorous testing for every batch, supporting third-party inspections.

- Comprehensive Product Range: Processed via slitting and shearing equipment, we also supply cold-rolled steel plates and cold-rolled steel strips. Our diverse product types eliminate the need for secondary processing.

- Reputation-Backed: Over 14 years of production and export experience, successfully serving over 120 countries worldwide. We are a certified “Contract-Honoring and Creditworthy” enterprise.

With numerous cold-rolled coil suppliers available, selecting a manufacturer with robust capabilities and a solid reputation is essential. Wanzhi Steel is a specialized cold-rolled coil supplier in China, headquartered in Boxing County, Shandong Province. Our facility boasts a professional technical team and a rigorous quality management system, producing cold-rolled coils with high dimensional accuracy, attractive surface finishes, and superior performance. For cold-rolled coil orders, please contact Wanzhi Steel anytime.