Metal roof sheet has become the most popular roof material in the market due to its corrosion resistance, long service life, convenient installation and strong decorativeness. It is widely used in factories, commercial buildings, residential areas and other fields. In addition, there are many types of metal roof sheets. Understanding the types and characteristics of metal roof sheets is important for choosing which metal roof sheet to use. This article mainly explains the types and characteristics of metal roof sheets.

Types of metal roof sheets

The types of metal roofs can be classified in two ways, one is by material, and the other is by installation methods.

1. Classification by material

Steel Metal Roof Sheets

The most commonly used steel metal roof sheets on the market are galvanized roof sheets and galvanized roofs. The surface can be painted, which is not only beautiful but also can increase the service life.

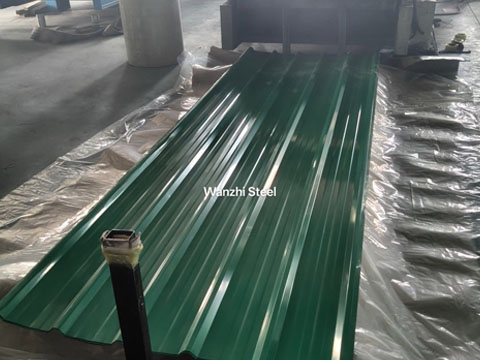

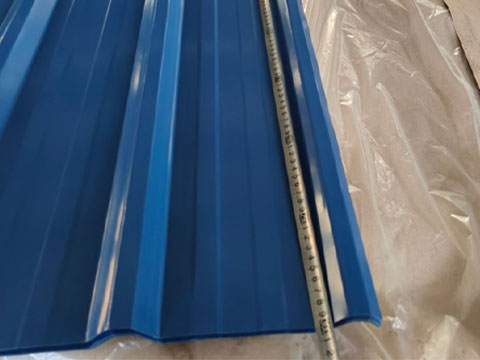

Pre-painted galvanized roof sheets: full size, multiple colors, customizable.

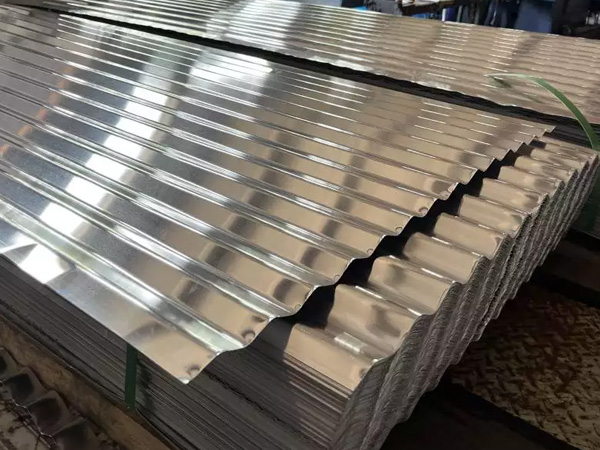

- Galvanized steel roof sheets: Galvanized steel roof sheets are the most commonly used steel metal roof sheets on the market. Galvanized steel roof sheets protect the steel sheets from corrosion by galvanizing the surface of the steel sheets.

- Galvalume roof sheet: Galvalume roof sheet is also common in the market, and it is not only galvanized, but also aluminum. Galvalume roof sheet has stronger corrosion resistance because it contains aluminum.

Wanzhi can provide galvanized and galvanized roof panels in various sizes and colors. Wanzhi has multiple tile pressing equipment that can produce different types of steel roof panels.

Aluminum metal roofing sheet

Aluminum roofing sheet is lightweight, corrosion-resistant, and durable in humid coastal areas.

Copper metal roofing sheet

Copper roofing sheet is a very durable roofing sheet and the most expensive metal roofing sheet.

Tin metal roofing sheet

Tin roofing sheet is not commonly used now. Most of the roofing sheets containing tin are steel combined with tin elements. Tin has similar properties to aluminum. In many cases, tin roofing sheet manufacturers produce less.

If you need an article to learn more about galvanized corrugated roof sheets:

WHAT IS CORRUGATED STEEL SHEETS?

Metal roofing sheets can be divided into the above 4 categories according to the material. These 4 types of metal roofing sheets have their own advantages and disadvantages. The following is a summary of their respective advantages and disadvantages.

| Metal roofing panels are classified by material | Advantages | Disadvantages |

| Steel roofing sheets | 1. Corrosion and rust resistance. 2. Lightweight and easy to install. 3. Lowest price among all metal roof panels. 4. Steel can be made into roof panels of various colors and shapes. 5. Durable and recyclable. | To avoid damage to your roof, you need to regularly clean it from leaves, branches, debris, and animal waste. |

| Aluminum roofing sheets | 1. Stronger corrosion resistance than steel roofs and rust-proof. 2. Lightweight and easy to install. 3. Strong plasticity. 4. Good thermal insulation performance, aluminum roofs can retain heat. 5. Aluminum roofs have a long service life and can be recycled. | 1. Aluminum is a soft material, so aluminum roofs are prone to dents. 2. Cost is more expensive than steel roofs. 3. Aluminum roof panels require more maintenance than steel roof panels. 4. They are prone to fading. |

| Copper roofing sheets | 1. Corrosion resistance. The rust produced by copper oxidation can protect the plate from corrosion. 2. Lightweight and easy to install. 3. Long service life. If the copper roof panel is properly installed and maintained, the service life can reach more than 80 years. | 1. The surface is prone to oxidation and discoloration. 2. Copper roof panels may cause stains on the exterior walls. This is due to rust caused by oxidation of the copper roof, which may be washed onto the wall by rain. 3. Copper roof panels are relatively expensive. |

| Tin roofing sheets | 1. Lightweight and easy to install. 2. Corrosion-resistant, with a service life similar to that of steel roof panels. | Tin roof panels are rarely used, there are basically no manufacturers to produce them, and they are difficult to buy. |

It is not difficult to see from the above table that steel roofing sheet is the most economical and practical, with good corrosion resistance and not very expensive.

Metal roofing sheet installation video

2. Classification by fixing method

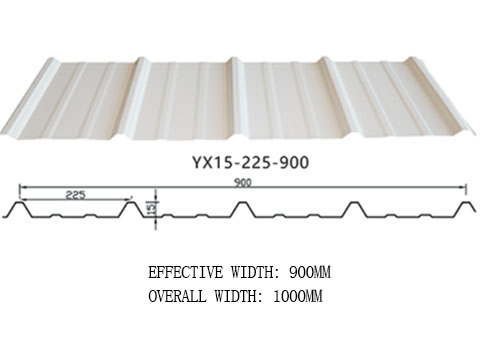

According to the different fixing methods of metal roofing sheets, they are divided into nail-through metal roofing system, concealed metal roofing system, upright bite edge metal roofing system, upright lock edge metal roofing system, and flat lock buckle plate metal roofing system. Below we introduce the materials used, common types/thicknesses, specifications, shapes, and applications of these five types of roofs.

| Roof panels Type | Materials | Common plate type or plate thickness | Specification | Roof panel shape | Application |

| Nailed metal roofing system | Corrugated color steel sheet, sandwich color steel sheet | Model: 820, 850, thickness standard: 0.5-1.2 mm, commonly used in the market: 0.4-0.6 mm | Usually width:600-1270mm | Straight | It is often used in buildings with short roofs and short service life. For example: canopies and temporary buildings. |

| Hidden-button metal roofing system | Galvanized and galvanized steel sheet, the parent material strength must reach G550. | Model: 406,760, thickness standard: O.6-1.2 mm, commonly used in the market: 0.5-0.6mm | Usually width:600-1100mm | Straight | It is widely used and is often used for large-span roofs with a single shape and not very high requirements. For example: single-slope or double-slope exhibition halls, workshops, factories, etc. |

| Standing seam metal roofing system | Galvanized, galvanized steel sheet, titanium zinc sheet, aluminum alloy sheet, copper sheet | Aluminum alloy plate 0.9mm, other materials 0.7mm, 0.8mm, mostly 0.7mm | Standard plate:430mm、530mm,Special-shaped plate:100-600mm | Straight, Fan, Arc, Fan-Arc | It is widely used and is generally used directly as a decorative surface. It can adapt to various roof forms. For example: ordinary roofs, complex urban sketches, factories, large stadiums, etc. |

| Standing seam metal roofing system | Galvanized, aluminum-zinc steel plate, titanium-zinc plate, aluminum-magnesium-manganese alloy plate (sprayed, natural color, hammer pattern) | Mostly use 0.9mm, 1.0mm | Standard plate:400mm,Special-shaped plate:100-500mm | Straight, Fan, Arc, Fan-Arc | It has a wide range of applications. It can be used directly as a decorative surface or as an extended double-layer roof. It can be mounted with various surface materials such as metal plates and stones. It is suitable for large-span metal roofs. For example: large stadiums, exhibition halls, museums, theaters, etc. |

| Flat-locking plate metal roofing system | Titanium zinc plate, copper plate, stainless steel plate | Thickness: 0.7mm, 0.8mm | Usually width:100-525mm | Mostly rectangular, diamond-shaped | It is widely used as a decorative surface. It is mostly used for small roof decoration layers. For example: villa roofs, residential building roofs, small exhibition halls, art galleries, etc. |

Performance comparison of different types of roof sheets

| Types of metal roof panels | Rainproof performance | Wind resistance | Ability to control thermal expansion and contraction | Is it easy to install |

| Nailed metal roofing system | The nail holes are prone to rain leakage | Strong | No, hot rolling and cold shrinkage may cause nails to shake | Very convenient |

| Hidden button metal roofing system | Strong | Good | Perfect thermal expansion and contraction compensation function | Convenient |

| Standing seam metal roofing system | Strong | Very strong | Good, suitable for moving distance of about 50mm | Relatively convenient |

| Standing seam metal roofing system | Strong | Strong | Perfect thermal expansion and contraction compensation function | Relatively convenient |

| Flat lock plate metal roofing system | It is open and requires an independent waterproof layer. | Fair | Has certain thermal expansion and contraction compensation function | Relatively complicated |

Features of metal roof sheets

1. Durability

Metal roof panels are corrosion-resistant, not easily affected by the environment, can resist wind pressure, rain and snow, ultraviolet rays, moisture-proof, lightning-proof, etc., and are relatively easy to maintain. The service life of metal roof panels can generally reach more than 50 years.

2. Strong functionality

On the premise of meeting the requirements of the building, metal roof panels can achieve the functions of load-bearing, anti-seepage, control of thermal expansion and contraction, insulation, and fire prevention.

3. Sound absorption and sound insulation

Metal roof panels can not only reduce the reflection of sound and achieve the sound absorption function. It can also prevent the indoor and outdoor transmission of sound and play a sound insulation role. Sound absorption and sound insulation are mainly achieved through the insulation cotton at the bottom of the metal roof.

4. Strong decorativeness

Metal roof panels have various shapes and colors, and can be customized according to different buildings. Wanzhi metal roof panels not only have various colors and shapes, but also can be customized with patterns, such as wood grain, stone grain, tile grain, etc. The appearance has a good visual effect.

5. Environmental protection and energy saving

Metal roof panels can be recycled, do not contain materials that release carbon dioxide, and will not pollute the environment. In addition, metal roof panels can reflect solar radiation heat, achieve heat insulation effect, and reduce indoor cooling costs.

6. Convenient installation and short construction period

Metal roof panels are light in weight, require fewer accessories, and are more convenient to install. In addition, the installation of metal roof panels is less affected by seasons and weather, which greatly shortens the construction period. It should be reminded that fixed facilities should be set on the metal roof during installation to ensure the safety of construction workers.

Conclusion

After understanding the types and characteristics of metal roof panels, you must have a general understanding of which metal roof panels to install. In general, when choosing metal roof panels, you need to consider your installation environment and budget. In view of the environment and budget, Wanzhi Steel recommends galvanized steel roof panels and aluminum-zinc roof panels for you. If you have other questions about metal roof panels, please contact Wanzhi Steel to answer them for you.