Definition of cold-rolled steel

Cold-rolled steel refers to various steels made by cold rolling process. Compared with hot rolling process, steel made by cold rolling process has brighter appearance, more precise size and higher strength.

Table of Contents

- Overview of cold-rolled steel specifications

- What are the categories of cold-rolled steel?

- Cold-rolled steel coil production process

- Properties of cold-rolled steel

- Applications of cold-rolled steel

- Conclusion

Overview of cold-rolled steel specifications

Size range of cold-rolled steel

- Thickness (mm): 0.30-4.00

- Width (mm): 600-2050 or as required

- Length (mm): 1000-6000 or as required

Allowable deviation of cold-rolled steel thickness (minimum yield strength less than 280MPa)

| Thickness(mm) | Thickness tolerance | ||||||||

| Normal precision PT. A | Higher precision PT.B | ||||||||

| Width(mm) | Width(mm) | ||||||||

| ≤1200 | >1200~1500 | >1500 | ≤1200 | >1200~1500 | >1500 | ||||

| ≤0.40 | ±0.04 | ±0.05 | ±0.06 | ±0.025 | ±0.035 | ±0.045 | |||

| >0. 40~0.60 | ±0.05 | ±0.06 | ±0.07 | ±0.035 | ±0.045 | ±0.050 | |||

| >0.60~1,80 | ±0.06 | ±0.07 | ±0.08 | ±0.040 | ±0.050 | ±0.050 | |||

| >0.80~1.00 | ±0.07 | ±0.08 | ±0.09 | ±0.045 | ±0.060 | ±0.060 | |||

| >1.00~1.20 | ±0.08 | ±0.09 | ±0.10 | ±0.055 | ±0.070 | ±0.070 | |||

| >1.20~1.60 | ±0.10 | ±0.11 | ±0.11 | ±0.070 | ±0.080 | ±0.080 | |||

| >1.60~2.00 | ±0.12 | ±0.13 | ±0.13 | ±0.080 | ±0.090 | ±0.090 | |||

| >2.00~2.50 | ±0.14 | ±0.15 | ±0.15 | ±0.100 | ±0.110 | ±0.110 | |||

| >2.50~3.00 | ±0.16 | ±0.17 | ±0.17 | ±0.110 | ±0.120 | ±0.120 | |||

| >3.00~4.00 | ±0.17 | ±0.19 | ±0.19 | ±0.140 | ±0.150 | ±0.150 | |||

Common cold-rolled steel plate grades include

Q195, Q215, Q235, SPCC, SPCD, SPCE, STCEN, ST12, ST13, ST14, ST15, ST16, DC01, DC03, DC04, DC05, DC06, etc.

What are the categories of cold-rolled steel?

Cold-rolled steel can be classified into ordinary carbon structural steel, high-quality carbon structural steel, low-alloy structural steel, cold-rolled stainless steel, low-carbon cold-rolled steel for enamel, etc.

Low-carbon cold-rolled steel

Classification

| Classification by use | Grade | Use |

| DC01 | General use | |

| DC03 | Stamping | |

| DC04 | For deep drawing | |

| DC05 | For extra deep drawing | |

| DC06 | For super deep drawing | |

| DC07 | For extra super deep drawing |

Grade and chemical composition

| Grade | C | Mn | P | S | Alt | Ti |

| DC01 | ≤0.12 | ≤0.60 | ≤0.045 | ≤0.045 | ≥0.020 | |

| DC03 | ≤0.10 | ≤0.45 | ≤0.035 | ≤0.035 | ≥0.020 | |

| DC04 | ≤0.08 | ≤0140 | ≤0.030 | ≤0.030 | ≥0.020 | |

| DC05 | ≤0.06 | ≤0.35 | ≤0.025 | ≤0.025 | ≥0.015 | |

| DC06 | ≤0.02 | ≤0.30 | ≤0.020 | ≤0.020 | ≥0.015 | ≤0.30 |

| DC07 | ≤0.01 | ≤0.25 | ≤0.020 | ≤0.020 | ≥0.015 | ≤0.20 |

Mechanical properties

| Grade | Yield strength/MPa | Tensile strength/MPa | Elongation after fracture | r90 | n90 |

| DC01 | 280 | 270-410 | 28 | ||

| DC03 | 240 | 270-370 | 34 | 1.3 | |

| DC04 | 210 | 270-350 | 38 | 1.6 | 0.18 |

| DC05 | 180 | 270-330 | 40 | 1.9 | 0.2 |

| DC06 | 170 | 270-330 | 41 | 2.1 | 0.22 |

| DC07 | 150 | 250-310 | 44 | 2.5 | 0.23 |

Equivalent standards

| GB/T 5213-2008 | GB/T 5213-2001 GB/T 13237-1991 | EN 10130-2006 | JIS G 3141-2005 | ISO 3574:1999 | ASTM A 1008M-07 |

| DC01 | 08AI | DCO1 | SPCC | CR1 | CS Type C |

| DC03 | DC03 | SPCD | CR2 | CS Type A,B | |

| DC04 | SC1 | DC04 | SPCE | CR3 | DS Type A,B |

| DC05 | SC2 | DCO5 | SPCF | CR4 | DDS |

| DC06 | SC3 | DC06 | SPCG | CR5 | EDDS |

| DC07 | DC07 |

Cold-rolled stainless steel(CRS)

Size range

| Shape | Thickness(mm) | Width(mm) |

| Wide steel strip, coiled steel plate | ≥0.10~<8.00 | ≥600~<2100 |

| Slitting wide steel strip, coiled steel strip | ≥0.10~≤8.00 | <600 |

| Narrow steel strip, coiled steel strip | ≥0.01~≤3.00 | <600 |

Thickness tolerance

| Thickness(mm) | Thickness tolerance | |||||

| Width(mm)≤1000 | 1000<Width(mm)≤1300 | 1300<Width(mm)≤210 | ||||

| Normal precision | Higher precision | Normal precision | Higher precision | Normal precision | Higher precision | |

| ≥0.10~<0.20 | ±0.025 | ±0.015 | ||||

| ≥0.20~<0.30 | ±0.030 | ±0.020 | ||||

| ≥0.30~<0.50 | ±0.04 | ±0.025 | ±0.045 | ±0.030 | ||

| ≥0.50~<0.60 | ±0.045 | ±0.030 | ±0.05 | ±0.035 | ||

| ≥0.60~<0.80 | ±0.05 | ±0.035 | ±0.055 | ±0.040 | ||

| ≥0.80~<1.00 | ±0.055 | ±0.040 | ±0.06 | ±0.045 | ±0.065 | ±0.50 |

| >1.00~<1.20 | ±0.06 | ±0.045 | ±0.07 | ±0.050 | ±0.075 | ±0.55 |

| ≥1.20~<1.50 | ±0.07 | ±0.050 | ±0.08 | ±0.055 | ±0.09 | ±0.60 |

| ≥1.50~<2.00 | ±0.08 | ±0.055 | ±0.09 | ±0.060 | ±0.10 | ±0.70 |

| ≥2.00~<2.50 | ±0.09 | ±0.10 | ±0.11 | |||

| ≥2.50~<3.00 | ±0.11 | ±0.12 | ±0.12 | |||

| ≥3.00~<4.00 | ±0.13 | ±0.14 | ±0.14 | |||

| ≥4.00~<5.00 | ±0.14 | ±0.15 | 士0.15 | |||

| ≥5.00~<6.50 | ±0.15 | ±0.16 | ±0.16 | |||

| ≥6.50~<8.00 | ±0.16 | ±0.17 | ±0.17 | |||

| Thickness(mm) | Thickness tolerance | |||||

| Width(mm)<125 | 125≤Width(mm)<250 | 250≤Width(mm)<600 | ||||

| Normal precision | Higher precision | Normal precision | Higher precision | Normal precision | Higher precision | |

| ≥0.05~<0.10 | ±0.10t | ±0.06t | ±0.12t | ±0.10t | ±0.15t | ±0.10t |

| ≥0.10~<0.20 | ±0.010 | ±0.008 | ±0.015 | ±0.012 | ±0.020 | ±0.015 |

| ≥0.20~<0.30 | ±0.015 | ±0.012 | ±0.020 | ±0.015 | ±0.025 | ±0.020 |

| ≥0.30~<0.40 | ±0.020 | ±0.015 | ±0.025 | ±0.020 | ±0.030 | ±0.025 |

| ≥0.40~<0.60 | ±0.025 | ±0.020 | ±0.030 | ±0.025 | ±0.035 | ±0.030 |

| ≥0.60~<1.00 | ±0.030 | ±0.025 | ±0.035 | ±0.030 | ±0.040 | ±0.035 |

| ≥1.00~<1.50 | ±0.035 | ±0.030 | ±0.040 | ±0.035 | ±0.045 | ±0.040 |

| ≥1.50~<2.00 | ±0.040 | ±0.035 | ±0.050 | ±0.040 | ±0.060 | ±0.050 |

| ≥2.00~<2.50 | ±0.050 | ±0.040 | ±0.060 | ±0.050 | ±0.070 | ±0.060 |

| ≥2.50~≤3.00 | ±0.060 | ±0.050 | ±0.070 | ±0.060 | ±0.080 | ±0.070 |

Ordinary carbon structural cold-rolled thin steel plate

Grade and chemical composition

| Grade | Chemical composition (mass fraction)/%≤ | ||||

| C | Si | Mn | P | S | |

| Q195 | 0.12 | 0.3 | 0.5 | 0.035 | 0.035 |

| Q215 | 0.15 | 0.35 | 1.2 | 0.035 | 0.035 |

| Q235 | 0. 22 | 0. 35 | 1.4 | 0.035 | 0.035 |

| Q275 | 0.24 | 0.35 | 1.5 | 0.035 | 0.035 |

Mechanical properties

| Grade | Yield strength/MPa | Tensile strength/MPa | Elongation after fracture/% | |

| Q195 | ≥195 | 315~430 | ≥26 | ≥24 |

| Q215 | ≥215 | 335~450 | ≥24 | ≥22 |

| Q235 | ≥235 | 370~500 | ≥22 | ≥20 |

| Q275 | ≥275 | 410~540 | ≥20 | ≥18 |

Cold-rolled steel coil production process

The production process of cold-rolled steel coil mainly includes: pickling → cold rolling → degreasing → annealing → leveling → shearing (cross-cutting, longitudinal cutting)

Properties of cold-rolled steel

- High hardness and strength: Cold-rolled steel is rolled at room temperature, and has higher hardness and strength than hot-rolled steel.

- Excellent processing performance: Cold-rolled steel has good plasticity and formability, and can be processed by stamping, cold cutting, bending, etc.

- Good surface quality: Cold-rolled steel has been rolled and stretched many times, making the surface glossy, without defects such as scale, pitting, rust, etc.

- Accurate size: The thickness and dimensional accuracy of cold-rolled steel are usually higher than those of hot-rolled steel, and the thickness difference is generally no more than 0.01-0.03mm or less, which can fully meet the requirements of high-precision tolerances.

- Toughness and weldability: The toughness and weldability of cold-rolled steel are relatively poor. It should be noted that cracks should be avoided during processing.

Applications of cold-rolled steel

Due to the good surface quality and precise size of cold-rolled steel, it is widely used in projects requiring high gloss and high precision. Typical applications include:

- Automobile manufacturing: automobile body, door, roof, wheel, chassis and other parts.

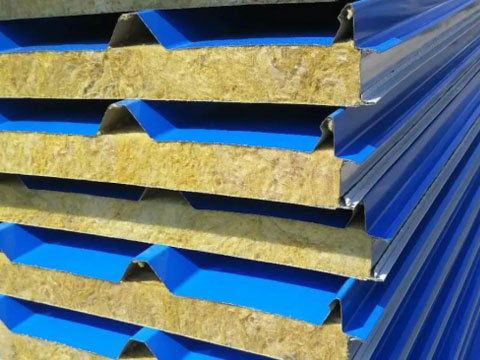

- Construction: building structures, industrial plants, warehouses, wall panels, roof panels, bridges, pipes, stairs, guardrails, etc.

- Home appliances: refrigerators, washing machines, air conditioners, microwave ovens and other home appliance shells and internal components.

- Packaging: food packaging, beverage packaging, cosmetics packaging, etc.

- Aerospace structures: aircraft parts and structural parts, aircraft engine parts and spacecraft shells, etc.

- Machinery manufacturing: commonly used in the manufacture of mechanical equipment, parts, tools, etc. in the machinery manufacturing field.

Conclusion

The cold-rolled steel supplied by Wanzhi Steel includes cold-rolled steel rolled on the basis of hot-rolled steel, and cold-rolled products processed by coil coating equipment, with metal materials or organic coatings on the surface of cold-rolled products.

- Coated cold-rolled products include galvanized steel, aluminum-zinc-coated steel, electro-galvanized steel, hot-dip galvanized steel, and electro-tinned (tinplate);

- Color-coated cold-rolled products include ppgi and ppgl.

If you have procurement needs for the above cold-rolled steel, please contact Wanzhi Steel.

This is our website: https://wanzhi-steel.com/

WhatsApp: +8615138685087

Email: info02@wanzhisteel.com