Coated steel, also known as plated steel. As an important metal material in modern industry, it plays a pivotal role in many industries with its unique anti-corrosion, aesthetic and processing properties. This is highly in line with WanZhi’s philosophy, which is pursuing excellence in product quality and meeting customer needs. It not only provides a strong and beautiful support for the construction industry, but also injects new vitality into the manufacturing industry such as home appliances and automobiles.

Simply put, coated steel is a product in which the surface of steel is coated with metals, alloys, organic coatings and plastics. It must be selected with good deep-drawing performance of low carbon plate, because the carbon content directly determines the yield strength of steel plate.

How Long Does Coated Steel Last?

Typically, coated steel has a service life of 10 years or more. It is determined by the material of the coating, the thickness of the coating, and the scenario of use. Typically lasts 20-30 years in industry. Provided that the plating is not damaged.

Factors affecting the service life of coated steel?

There are five specific factors that influence this:

1. Surface Treatment Of Steel

The quality of surface preparation has a significant impact on coating adhesion. If there are defects such as oil and rust on the steel surface, it will reduce the adhesion of the coating, thus affecting the service life of the coated steel.

2. Environment Of Use

In harsh environments such as high temperature, high humidity, and high salt, corrosion and aging of the coating becomes accelerated, and the life of the coated steel is shortened.

3. Construction And Maintenance:

The quality of the coating’s construction and subsequent maintenance also affect the service life. Improper construction can lead to coating defects such as bubbles and cracks. And the lack of maintenance will make the coating can not be repaired in time after the damage, thus affecting its anti-corrosion performance.

4. Coating Quality And Type

High-quality coatings provide better isolation of the steel from the external environment, resulting in a longer service life. Different types of coatings, such as organic and inorganic coatings, have different corrosion resistance properties. Suitable for different usage environments and scenarios

5. Coating Protection Technology

Such as the strength of the bond between the coating and the steel, the film thickness, and the type of paint and metal composite coating. Also affects the service life of the coated steel. These technical factors dictate whether the coating isolates the steel from the harsh environment. Thereby extending its service life.

In summary, the using life of coated steel is affected by a number of factors, including the quality and type of coating, the surface treatment of the steel, the environment in which it is used, construction and maintenance, and the coating protection technology. Therefore, these factors need to be taken into account when selecting and using coated steel. To ensure long service life and good performance of the coated steel.

Where Is Coated Steel Used?

Coated steel is used in several industries, thanks to its plating, which resists corrosion and also serves an aesthetic purpose. Inherently good machinability, robustness, and durability are highly favored by the manufacturing industry. The following are some of the main areas of application for coated steels

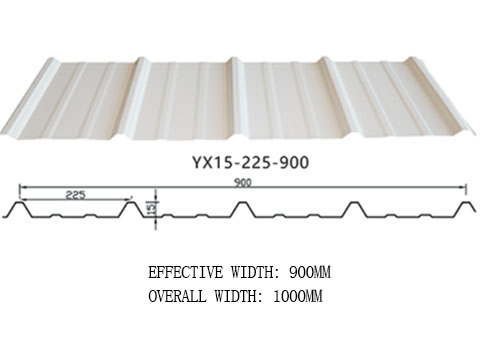

1. Construction

It is used to make roofing, wall panels, parapets and other building materials, and its corrosion resistance and good weather resistance can extend the service life of building materials.

2. Automotive industry

Often used for body panels, doors, hoods, and other parts, its corrosion resistance can effectively prevent corrosion of automobiles in harsh environments.

3. Appliances

Manufacture of refrigerators, washing machines, air conditioners and other electrical appliances shell, not only the appearance of bright, but also good corrosion resistance

4. Metal Processing

Manufacture of metal products such as furniture, hardware fittings, etc.

5. Transportation

Electricity pylons, communication pylons, railway, road protection, street light poles.

In addition to the above industries, coated steels are used in a variety of other applications, such as marine components, structural steel components for buildings, substation accessories, and light industry.

Can Coated Steel Rust?

Theoretically, it won’t rust if the plating is thick enough. Because the special coating on the surface prevents steel from contact with the environment, to achieve rust prevention. However, whether or not coated steel will rust also depends on a variety of factors. Here are 3 main factors:

1. Environmental Factors

In the presence of oxygen and humidity, the surface of steel tends to oxidise and form oxides of steel, which leads to rusting. Especially in high temperature and high humidity environments, the surface coating of steel is susceptible to corrosion, resulting in the formation of rust spots.

2. Quality Of Coated Steel

If the coating has poor quality, or if the coating has been damaged during construction. Both may cause the coating to lose its protective effect, exposing the steel to the elements and rusting. WanZhi’s raw materials for coated steel are of reliable quality and stable performance. If you are looking for materials, then Wanzhi is your first choice!

3. Conditions Of Storage And Transport

If suitable protective measures are not taken during storage and transport. The surface of coated steel can be mechanically damaged, which makes the steel susceptible to oxygen and water attack. Then rust spots formed.

How Is Coated Steel Plated?

The production process may vary for different types of coated steel. The specific process should be adjusted according to actual demand and product characteristics. General steps that are commonly used are as follows:

1.Surface Treatment:

This is the pre-treatment stage, which is needed to make the surface of the steel clean and smooth.This step directly affects the adhesion and corrosion resistance of the coating. Commonly used surface treatments are mechanical and chemical. Mechanical treatment mainly removes dirt from the steel surface by sandblasting or grinding. Chemical treatment is the use of acid, alkali solutions or other solutions to produce a chemical reaction on the surface. To change the physical and chemical properties of the steel surface.

2. Coating Preparation

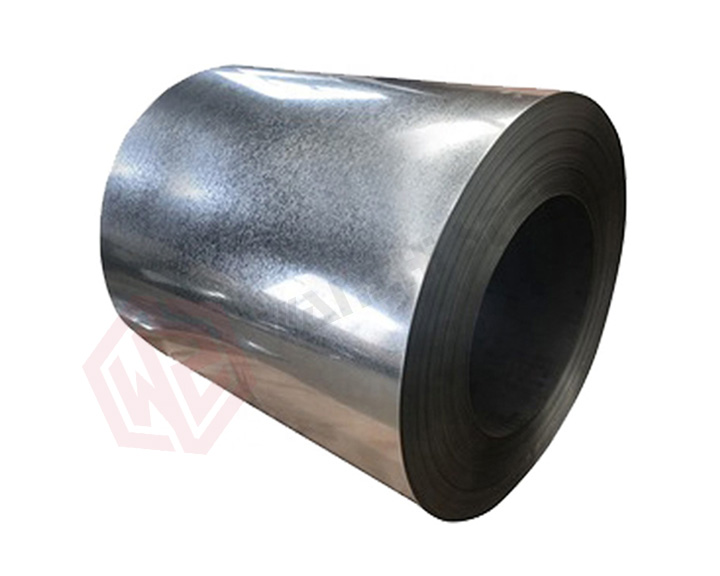

This is the core part. Coatings are divided into two main categories of organic and inorganic coatings. Organic coating means resin coating. Such as epoxy and polyethylene powders. They improve the corrosion resistance and aesthetics of the steel. Inorganic coatings are metallic coatings. For instance, a galvanized coating gives the steel higher corrosion resistance and longer service life.

3. Coating

The prepared coating material is uniformly applied to the steel surface. There are various methods of coating, including spraying, brushing, and dipping. During the coating process, it is necessary to control the thickness and uniformity of the coating. Ensure that the coating covers the steel surface completely and avoids leakage, dripping, and blistering.

4. Baking And Curing

Drying and curing after the coating is applied. Drying mainly removes solvents or other volatiles from the coating, which can be done by natural drying or heat drying. Curing is the reaction of chemicals in coating material to form a hard, non-peeling coating. The curing temperature and time are determined by the nature and thickness of the coating.

It is important to note that, during the production process, it is also necessary to strictly control the quality of each link. To ensure that the quality and performance of the coated steel meets the requirements.

Conclusion

After the above, I believe you are no longer unfamiliar with coated steel. As a high-performance, multi-functional material, it has become the first choice of many companies in pursuit of innovation and quality, thanks to its robustness, elegance, corrosion resistance, and high workability. Light steel keel, corrugated board, refrigerator, washing machine shell, and car frame are taken from plated steel.

It can be made into GI(Galvanized Steel) /GL(Gavalume Steel) /PPGI(Color-Coated Steel)…are available for sale at WanZhi.