In recent years, products using hot-dip galvanizing technology have become increasingly popular. Many building materials are made of hot-dip galvanized products, such as highway guardrails, street light poles, roof panels, fences, etc. Why are hot-dip galvanized products so popular? What is the process of hot-dip galvanizing? What are the advantages of hot-dip galvanizing? This article explains it in detail.

What is hot dip galvanizing

To understand what hot-dip galvanizing is, you can first understand the meaning of hot-dip galvanizing. Hot-dip galvanizing is the abbreviation of hot-dip galvanizing, which is a method of immersing metal materials in other liquid metals or alloys with lower melting points for coating. Plating technologies include tank plating, barrel plating, automatic plating, continuous plating, etc. After understanding the meaning of hot-dip galvanizing, the following will introduce the base materials and coating materials of hot-dip galvanizing.

1. Hot-dip base material

There are many base materials for hot-dip, and the most commonly used is steel. In China, there is information that class B steel in Q235 steel is most suitable for hot-dip galvanizing.

2. Hot-dip coating materials

Commonly used coating materials for hot-dip include zinc, aluminum, tin, lead, etc. Among these coating metals, zinc is a cheap and easy-to-plate metal.

Because zinc is a cheap and easy-to-plate metal, hot-dip galvanizing is more popular. Let’s take a closer look at the hot-dip galvanizing process.

3. Hot-dip galvanizing process

Hot-dip galvanizing is to immerse the pretreated steel in molten zinc liquid, so that the steel and zinc liquid react chemically to form an iron-zinc alloy anti-corrosion layer, which can well protect the substrate and avoid it from the threat of corrosion.

The hot-dip galvanizing process generally includes the pretreatment of steel, immersion of steel in zinc liquid at 440-450℃, cooling, passivation, inspection and other steps.

The pretreatment of steel is mainly to remove impurities on the surface of steel and ensure that the steel and zinc layer are tightly combined. Steel pretreatment includes: degreasing, pickling, water washing, plating aid, and drying.

Degreasing treatment is mainly to deal with grease on the surface of steel.

Hydrochloric acid pickling is to deal with rust on the surface of steel. Water washing is an important part of the hot-dip galvanizing process. The purpose is to remove iron salts on the surface of steel and reduce the excessive production of zinc ash and zinc slag in subsequent processes.

Plating aid is to make up for the deficiencies in the previous process. On the one hand, it removes any residual oxides on the surface of steel. On the other hand, it forms a protective layer on the surface of steel to prevent oxidation of steel before galvanizing and improve the quality of galvanizing.

Drying is to remove the steel from the plating aid, remove excess moisture on the surface, and avoid zinc explosion and leakage during galvanizing.

Advantages of hot-dip galvanizing

1. Strong corrosion resistance

Zinc has good corrosion resistance. Hot-dip galvanizing can form a tight iron-zinc alloy layer with steel, which can isolate steel from reacting with corrosive media and prevent steel from being corroded.

2. Relatively low cost

As mentioned earlier, zinc is the cheapest compared to other coating materials, and hot-dip galvanizing can meet your anti-corrosion needs. Galvanizing has relatively low initial cost and later maintenance cost.

Recommended products for you: hot-dip galvanized steel

3. Long life

Hot-dip galvanized products are durable, and the galvanized coating can be used for more than 50 years. Steel produced by hot-dip galvanizing generally does not need to be repaired within 20 years.

4. Strong coating

The coating produced by hot-dip galvanizing is usually thicker, strong, hard, and wear-resistant, and can resist external wear very well.

5. Low maintenance cost

Products produced by hot-dip tinning require less maintenance because the coating is thicker and all surfaces of the steel can be covered, and generally do not need to be repaired within 20 years.

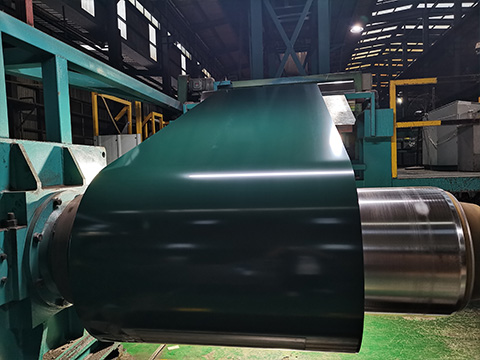

6. Beautiful appearance

The hot-dip galvanized coating has a good glossiness, the coating is continuous and uniform, and the galvanized steel has a good decorative effect.

7. Can shorten the construction period

The hot-dip galvanizing process is simple, the production cycle is short, and it is faster than other coating methods. The steel products that have completed hot-dip galvanizing can be put into use directly, which greatly shortens the construction period.

What are the hot-dip galvanized products?

Hot-dip galvanized products can be classified according to different coatings and steel types.

Common hot-dip galvanized coatings include hot-dip pure zinc, hot-dip galvanized iron alloy, hot-dip galvanized aluminum, hot-dip aluminum-zinc, hot-dip aluminum-silicon, and hot-dip zinc-aluminum-magnesium.

According to different coatings, hot-dip galvanized products include hot-dip galvanized steel, hot-dip galvanized aluminum steel, hot-dip aluminum-zinc steel, hot-dip aluminum-silicon steel, hot-dip galvanized aluminum-magnesium steel (zam steel), etc.

| Hot dip galvanized products | Ingredients |

| Hot-dip galvanized steel | The zinc content should be no less than 99% |

| Hot-dip galvanized aluminum steel | About 5% aluminum (Al) and a small amount of rare earth elements, the rest is zinc. |

| Hot-dip aluminum-zinc steel | About 55% aluminum (Al) and about 1.6% silicon, the rest is zinc. |

| Hot-dip aluminum-silicon steel | About 8% to 11% silicon (Si), the rest is aluminum. |

| Hot dip galvanized aluminum magnesium steel | The sum of aluminum and magnesium is usually 1.5~8%, the rest is zinc. |

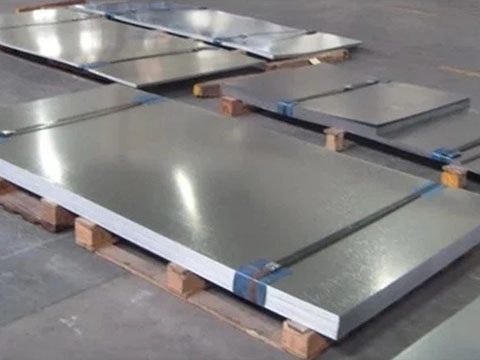

According to the different types of galvanized steel, common hot-dip galvanized products include galvanized steel sheets and strips, galvanized steel wires, steel wire mesh, galvanized steel pipes, and galvanized pipe fittings.

Hot dip galvanized product application

Hot-dip galvanized products are widely used in the fields of automobiles, construction, electricity, transportation, etc.

1. Automobile field

In the automobile field, hot-dip galvanized products are widely used in the manufacture of parts exposed to the external environment for a long time due to their excellent corrosion resistance and tensile strength, which can improve the corrosion resistance of automobile parts and extend the service life of the car.

2. Construction field

In the construction field, many metal fasteners are exposed to the outdoor environment for a long time. In order to prevent these fasteners from corrosion, merchants will use hot-dip galvanized fasteners to protect the building structure from corrosion. For example, steel bars, steel plates, scaffolding, bridge structures, fences, etc. in the construction field are all made of hot-dip galvanizing process.

3. Electric power field

In the electric power field, hot-dip galvanizing process is used in power transmission towers, substation facilities, wire casings, high-voltage transmission lines, line hardware, microwave towers, communication towers and other power equipment by utilizing the anti-corrosion ability of hot-dip galvanizing.

4. Transportation industry

In the transportation industry, hot-dip galvanized products are widely used. Highway guardrails, highway sign poles, street lamp poles, highway and high-speed rail sound wave barriers and other products are all made of hot-dip galvanizing process.

In addition to the above applications of hot-dip galvanized products, hot-dip galvanizing is also widely used in the fields of petrochemicals and aerospace. For example, hot-dip galvanized products are used in pipes, valves, pumps, etc. in the petrochemical field. Hot-dip galvanized products are used in aviation equipment in aerospace.

Which is better, hot-dip galvanizing or cold-dip galvanizing?

Hot-dip galvanizing and cold-dip galvanizing each have their own advantages and disadvantages. Which galvanized product to choose depends on your usage scenario and budget.

| Name | Hot-dip galvanizing | Cold-dip galvanizing |

| Zinc layer thickness | 30-60μm | 3-15μm |

| Process characteristics | The treated steel is immersed in zinc liquid with a certain temperature to form a compact, uniform and highly adhesive zinc layer. | The process is relatively simple. Electro-galvanizing uses electric current to galvanize the surface of steel. |

| Corrosion resistance | Hot-dip galvanizing has stronger corrosion resistance due to the formation of a zinc-iron alloy layer. | Cold-dip galvanizing has weaker corrosion resistance than hot-dip galvanizing. |

| Cost | The process is relatively complicated and the cost is relatively high. | The process is simple and the cost is low. |

| Surface finish | The outer surface of hot-dip galvanizing is rough, darker in color, and generally silvery white. | The surface of cold-dip galvanizing is also smoother and brighter. |

| Application range | Suitable for highly corrosive environments. | Suitable for indoor environments, generally used for pipes, thin plates, small fasteners, indoor steel plates, etc. |

了解热镀锌与冷镀锌的区别:热镀锌钢板和电镀锌钢板的区别

In general, hot-dip galvanized products have good corrosion resistance, poor decorative effect, and relatively high prices. Cold-dip galvanized products have relatively low prices and poor repetitive performance. They are more suitable for places with low requirements for corrosion resistance and durability. To choose which galvanizing method, we need to consider the environment, climate and cost factors of the application site.

Conclusion

Hot-dip galvanized steel is widely used in various industries due to its excellent corrosion resistance, wear resistance, toughness and other characteristics. As a Chinese hot-dip galvanized steel manufacturer, Wanzhi Steel has two hot-dip galvanizing production lines and sells them at factory prices with high product quality. If you need hot-dip galvanized steel, please contact us for a quote.