PPGI and PPGL are both color-coated steel, and they have many similarities. However, there are differences in performance and application between PPGI and PPGL. These differences are very important for us to decide whether to choose PPGI or PPGL when applying. This article mainly introduces the main differences between PPGI and PPGL.

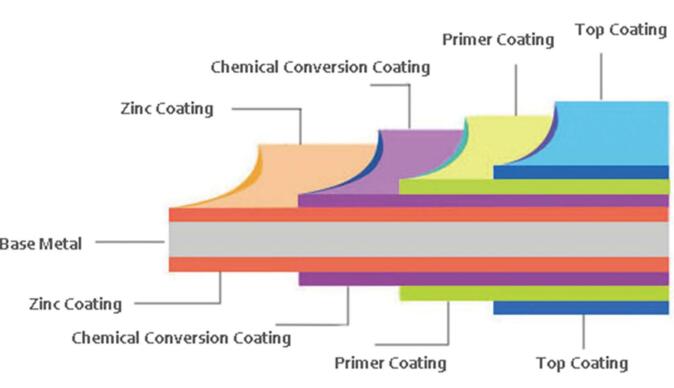

The substrates of ppgi and ppgl are different

As can be seen from the names of the two, PPGI is Pre-Painted Galvanized, PPGL is Pre-Painted galvanlume, the substrate used by ppgi is galvanized sheet, and the substrate used by ppgl is galvanized sheet. The basic difference directly determines the performance difference between the two. Galvanized steel contains 43.3% zinc, 55% aluminum, and 1.6% silicon. These ingredients make galvanized steel more corrosion-resistant than galvanized steel.

The applications of ppgi and ppgl are different

- PPGI is often used for various roof and wall coverings.while PPGL has good weather resistance and corrosion resistance and is more suitable for harsh outdoor environments.

- PPGI is often used in building wall panels, roofs, warehouses, shopping malls and other fields.

- PPGL is often used in the manufacture of home appliance housings, automobile housings and other fields. PPGL also has excellent heat resistance and is often used in chimney pipes and ovens.

The prices of ppgi and ppgl are different

Because PPGL has stronger performance than PPGI, longer service life, and fewer manufacturers, the price of ppgl is usually higher than ppgi.

Wanzhi is a manufacturer specializing in the production of ppgi and ppgl. Welcome to contact us for product consultation.

When deciding to choose ppgi and ppgl, not only the initial cost should be considered, but also the total cost of ownership during the service life. Ppgl is more suitable for long-term applications or large-volume customers, while ppgl is more suitable for customers with limited budgets or low application time requirements.

The lifespan of PPGI and PPGL is different

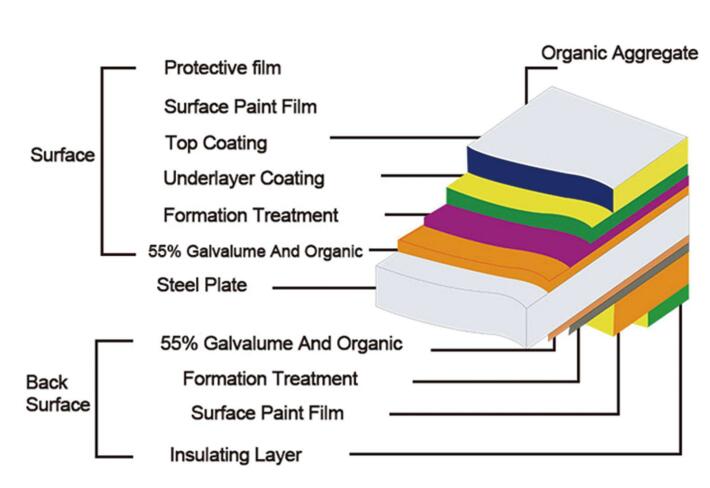

- The surfaces of PPGI and PPGL are coated to protect them from rust.

- PPGI is a galvanized coating, and PPGL is aluminum zinc coating.

- For zinc coating, if the zinc layer is completely corroded, the metal inside will be destroyed, so the lifespan of PPGI is generally 10-15 years.

- For Aluminum zinc coating, PPGL contains aluminum, which makes it more corrosion-resistant and can maintain good appearance and performance in harsh environments. The service life of PPGL is generally 3 times that of PPGL.

In oIn order to ensure the life of steel, the coating weight recommended for use in different corrosion environments is as follows:

| Substrate type | Nominal coating weight (g/m²) | ||

| Corrosive environment | |||

| Low | Medium | High | |

| Hot dip galvanized substrate (Z) | 90/90 | 125/125 | 140/140 |

| Hot-dip galvanized iron alloy substrate (ZF) | 60/60 | 75/75 | 90/90 |

| Hot-dip aluminum-zinc alloy substrate (AZ) | 50/50 | 60/60 | 75/75 |

| Hot-dip galvanized aluminum alloy substrate (ZA) | 65/65 | 90/90 | 110/110 |

| Electrogalvanized substrate (ZE) | 40/40 | 60/60 | – |

Source: https://wanzhi-steel.com/ppgi-ppgl/ppgi-ppgl-specifications/

The weight of PPGI and PPGL is different

Because the specific gravity of aluminum is less than that of zinc, under the same thickness of coating, the galvanized coating is lighter than the galvanized coating. It can be recommended that the galvanized coating should cover 3% more space than the galvanized coating under the same weight.

Formula for calculating the weight of color-coated steel sheets: Thickness (mm) * Width (m) * Length (m) * Density = Weight (kg/pcs)

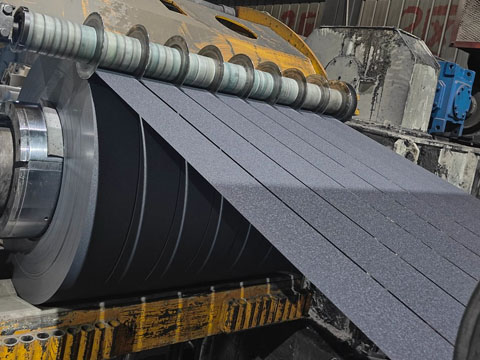

The appearance of PPGI and PPGL is different

The difference between the appearance of PPGI and PPGL is that PPGI is more shiny and smoother than PPGL. In addition, PPGI is more customizable than PPGL, and can create more appearance effects, such as metal effects and textured finishes. The finishes that PPGL can use include smooth, embossed or matte surfaces.

The performance of PPGI and PPGL is different

The performance difference between PPGI and PPGL can be explained from the following points:

- Heat resistance: Because of the different zinc layer, PPGL has higher heat resistance than PPGI, and PPGL can withstand high temperatures of 315℃.

- Flexibility: PPGL is more flexible than PPGI and is easier to bend.

- Corrosion resistance: Since PPGL is an aluminum-zinc alloy coating, the dense layer formed by aluminum can prevent further corrosion of the base metal, so PPGL has better corrosion resistance than PPGI.

The production process of ppgi and ppgl is different

The production process of ppgi and ppgl is also different. The production process of ppgi is not complicated and the production cycle is shorter, while the production process of ppgl is complicated, the process is cumbersome, and the production cycle is long.

Conclusion

The difference between ppgi and ppgl is as above. Both have advantages and disadvantages. When making a choice, you should consider the application environment of your project and the required service life. If the customer is sensitive to price and has high requirements for appearance, it is recommended to choose ppgi; if the customer needs to use it in a harsh environment and has requirements for service life, it is recommended to choose ppgl.

At Wanzhi, we produce high-quality color-coated steel products, including ppgi and ppgl. We provide you with ppgi and ppgl in a variety of colors and sizes. We only purchase high-quality raw materials to ensure the durability of our products.