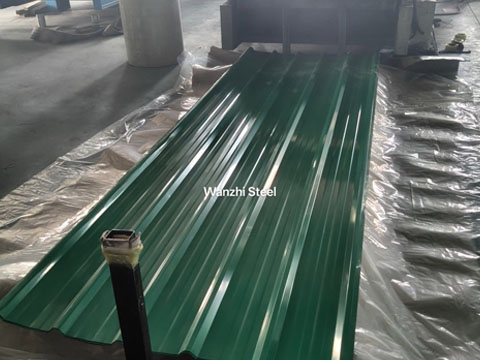

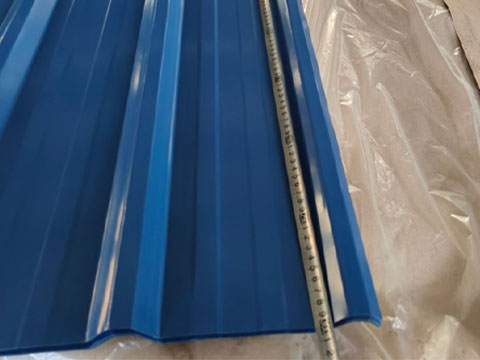

The client is a general contractor for warehouse facility construction in Uruguay. The 150 tons of color-coated coils procured will be used for roofing and wall construction in a large-scale modern grain drying and storage integrated workshop they are undertaking.

Client Requirements

- The client procures 150 tons of 0.4mm RAL7024 color-coated steel coils. Uniform specifications and color facilitate large-scale procurement, transportation, and installation.

- Each coil must not exceed 3.5 tons in weight, as the client’s crane has a maximum lifting capacity of 3.5 tons.

- All goods must be produced by early March 2026, as the client’s project commencement date is scheduled for late March. Materials must arrive at the Uruguayan port by late March to align with the construction schedule.

Developing the Solution

Addressing Weight Requirements

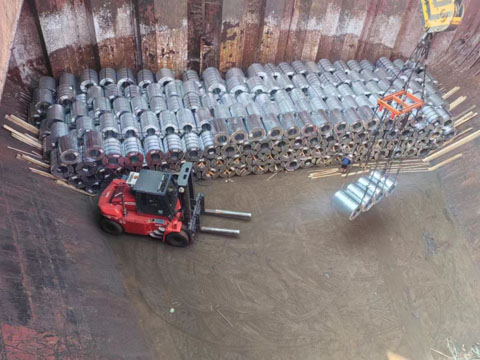

Upon receiving the inquiry, we immediately focused our communication on “weight control.” We explained that standard coil weights range from 3 to 8 tons. To consistently achieve 3.0 tons per coil, we would adjust the rolling program and activate a precision online weighing system. We committed to weighing each coil twice during production (post-coiling and pre-packaging) and listing actual weights on the final packing list to absolutely meet their crane safety requirements.

Addressing Delivery Requirements

To meet the customer’s urgent need to “catch the earliest post-holiday shipment,” we immediately launched the “Pre-Spring Festival Material Preparation, Post-Holiday First Shipment” special plan:

- Pre-holiday (by February 1, 2026): Complete procurement and production scheduling for all DX51D base sheets, commence production planning. The customer requires a single specification, enabling batch production.

- Post-holiday (late February 2026, after factory resumption): Immediately execute final coil splitting, precise weighing, packaging, and port consolidation operations, targeting shipment by late February.

After receiving our solution proposal, we conducted a live demonstration showcasing our production lines, samples, testing center, and certifications. This addressed the customer’s concerns, leading to their decision to partner with us.

Order Details

| Project Name | Supply of Color-Coated Roofing/Walling Materials for Modern Grain Storage Facilities in Uruguay |

| Procurement Country | Uruguay |

| Core Products | RAL 7024 Color-Coated Steel Coil |

| Product Specifications | Thickness: 0.40mm, Width: 1220mm |

| Color | RAL 7024 |

| Procurement Quantity | 150 Tons |

| Substrate and Coating | DX51D+Z30 |

| Core Requirements per Roll | <3.5 Tons |

| Packaging Method | Standard export rust-proof packaging, each coil clearly marked with a unique serial number and actual weight. |

| Trade Terms | CIF (Port of Destination: Montevideo, Uruguay) |

| Payment Method | 30% Wire Transfer Prepayment + 70% Balance |

Reasons for Client Selection

- Ability to rapidly develop tailored solutions while ensuring thorough, comprehensive communication.

- Three color-coated coil production lines enabling swift processing of large-volume orders with expedited delivery.

- Certified enterprise compliant with ISO 9001, ISO 14001, CE, and other standards, recognized as a trustworthy metal materials supplier.

Wanzhi Steel boasts over 15 years of experience. Our color-coated steel coil colors are based on the RAL color chart, offering a wide range of options. For any color-coated steel coil requirements, please feel free to contact us.