Galvanizing is the process of coating steel with zinc to prevent it from rusting, because the zinc layer can form a physical and chemical barrier around the steel, which can prevent the steel from rusting, thereby increasing its service life.

When it comes to galvanized products, the common ones include hot-dip galvanized steel and electro-galvanized steel. Both are galvanized steel, but there are differences. This article mainly introduces the difference between hot-dip galvanized steel and electro-galvanized steel.

Differences in production processes

Hot-dip galvanizing process: The production process of hot-dip galvanizing is complicated. The steel must go through processes such as degreasing, pickling, dipping, and drying, and then immersed in a zinc pool. The temperature in the zinc pool is about 500 degrees. This temperature can well combine the zinc layer with the steel, and the thickness of the zinc layer is also very thick, and the anti-corrosion ability is very strong.

If you need an article that goes more in depth into hot-dip galvanized steel:

WHAT IS HOT-DIP GALVANIZED STEEL

Electro-galvanizing process: The production process of electro-galvanized steel is simple. Electro galvanized steel is galvanized on the surface of the steel by electric current, so the zinc layer formed will be relatively thin.

Difference in zinc layer thickness

The zinc layer thickness of hot-dip galvanized steel is relatively thick, generally 30-60μm, and can reach more than 200μm. The minimum galvanizing amount of hot-dip galvanized steel is 50-60g/㎡, and the maximum can reach 600g/㎡.

The thickness of the electro-galvanized zinc layer is relatively thin, usually only 3-15μm. The minimum galvanizing amount of electro-galvanized steel is 15g/㎡, and the maximum is 100g/㎡.

In addition, there is a compound layer between the zinc layer of hot-dip galvanized steel and the steel plate. When the zinc layer crystallizes, zinc flowers will form, and the zinc layer is uniform. The zinc atoms of galvanized steel are attached to the steel surface by physical action, which will produce many gaps and are easily corroded, so hot-dip galvanized steel is more corrosion-resistant than electro-galvanized steel

Difference in service life

The zinc layer of hot-dip galvanized steel is thick and uniform, and its corrosion resistance is stronger than that of electro-galvanized steel. In terms of service life, hot-dip galvanized steel is far higher than electro-galvanized steel.

The service life of hot-dip galvanizing can reach 15-20 years in harsh industrial and coastal environments, and can reach more than 30 years in general environments. The service life of electro-galvanized steel is generally about 10 years.

Price difference

Generally speaking, the thicker the coating, the more expensive it is. Hot-dip galvanizing is 8-10 times more expensive than electro-galvanizing. Although hot-dip galvanizing is more expensive, it is durable, which will reduce the subsequent maintenance costs and has a long service life. In harsh environments, hot-dip galvanized steel plates are still selected for long-term considerations.

Electro-galvanized steel is cheap. If your use environment is not very harsh and you do not consider the long-term use effect, you can consider electro-galvanizing steel.

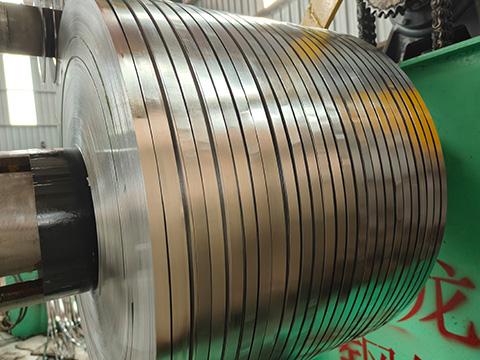

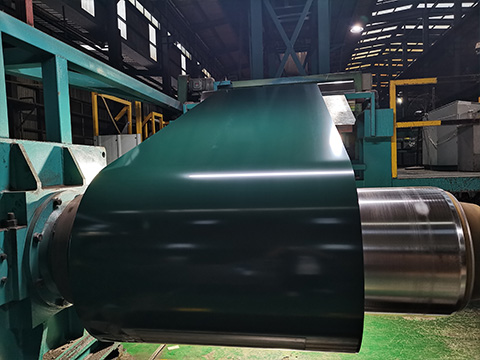

Different appearance

Because the hot-dip galvanizing zinc layer is thick and the zinc layer is thick, the surface will be rough, there will be some process water marks, and some will show zinc flowers, which will not reflect light. The overall color of hot-dip galvanizing is silver-white.

The appearance of electro-galvanizing is relatively smooth and bright, and the colors are mainly yellow-green and bluish-white.

Different scope of application

The zinc layer of hot-dip galvanizing is thicker, and the anti-corrosion ability of the zinc layer is higher, which is suitable for outdoor environments.

- Construction field: such as bridges, buildings and building materials, etc. Steel structure and steel connection accessories.

- Automotive field: car doors, frames, bodies, chassis, roofs, engine hoods and other automotive parts.

- Petrochemical field: Petrochemical applications are commonly used in the manufacture of petrochemical equipment, oil pipelines, oil storage tanks, oil and gas recovery pipelines, etc.

- Transportation field: highway fences, highway signs, street lamp poles, etc.

The electro-galvanized zinc layer is thinner and has relatively poor corrosion resistance. It is suitable for indoor environments and is generally used for pipes, thin plates, small-size fasteners, indoor steel panels, etc.

Conclusion

Both hot-dip galvanized steel and electro-galvanized steel are galvanized steel. In comparison, each has its own advantages. When choosing which galvanized steel to use, you should consider the environment in which you use it and the acceptable cost. Wanzhi Steel has 3 galvanizing production lines. If you need to purchase galvanized steel, please contact Wanzhi for details.