ZAM Steel

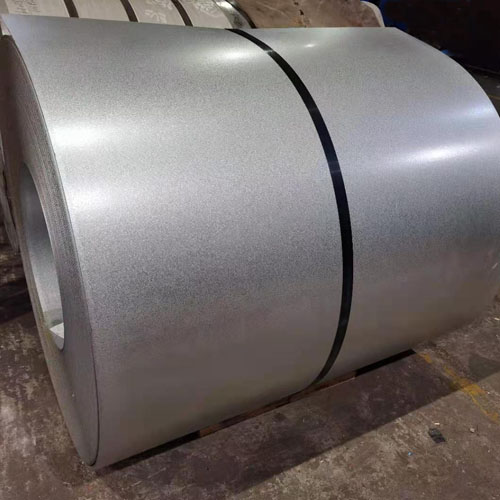

Wanzhi Steel has a zam steel production line that can produce zinc-aluminum-magnesium coated steel in various sizes with a monthly production capacity of 10,000 tons. Samples can be provided free of charge. If necessary, please feel free to contact us.

Thicknesses: 0.3mm-4mm

Width: 600mm-1,500mm

Coating thickness: 60-180g/㎡

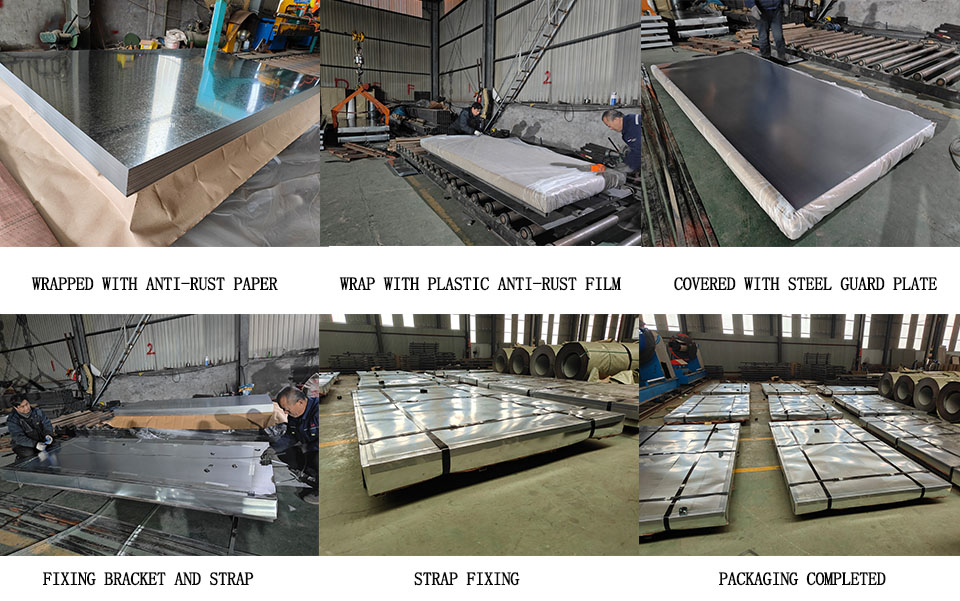

Packaging :Standard export packaging (waterproof paper inside and steel strap outside)

Loading Port:Tianjing Qingdao Shanghai or as required

Ensure product quality and transportation

ZAM steel is also called zinc-aluminum-magnesium coated steel. The biggest feature of zinc-aluminum-magnesium coated steel is its self-repairing ability and strong corrosion resistance.

Aluminum-magnesium-zinc steel is a new type of steel with corrosion resistance 10-20 times that of galvanized steel coil. Its rust resistance can reach the standard of stainless steel, but its price is lower than that of stainless steel. Wanzhi Steel has a galvanized aluminum-magnesium production line with an annual output of 200,000 tons, which can deliver quickly.

Wanzhi zam steel specifications

| Product Name | ZAM steel |

| Base Metal | Cold rolled steel |

| Thicknesses | 0.3 – 4mm |

| Width | 600-1500mm |

| Coating thickness | 60-180g/㎡ |

| Surface treatment | Passivation, Fingerprint resistance, Oil coating |

| Grade | SPHC, SPHD, SPHE, DX51D, DX52D, DX53D, SPCC, SPCD, A1006, A1008, etc |

| Value-added services | Cutting, slitting, shearing |

| MOQ25 | 25 tons |

| Packing | Standard export packaging (waterproof paper inside and steel strap outside) |

ZAM Steel Chemical Composition and Its Corresponding Effects

Chemical Composition

| Chemical composition of substrate (taking DX51D as an example) | C | Mn | P | S | Fe |

| ≤0.12% | ≤0.50% | ≤0.045% | ≤0.045% | Remainder | |

| Coating chemical composition | Zn | Al | Mg | Si | Fe |

| 55% – 65% | 20% – 30% | 1.5% – 3.5% | 0.1% – 0.5% | ≤0.3% |

Effects of Composition

- Zinc (Zn): Provides basic cathodic protection (sacrificial anode) function.

- Aluminum (Al): Forms a dense aluminum oxide barrier, preventing the intrusion of corrosive media.

- Magnesium (Mg): Aluminum and zinc create a synergistic effect, promoting the formation of dense, stable corrosion products that coat cuts and scratches, achieving a “self-healing” effect and significantly improving corrosion resistance in harsh environments.

Production video

Application of zam steel

- Architecture: perforated plates, metal facades, roofs, keel ceilings, cable trays, building panels, etc.

- Agriculture and livestock: greenhouse steel structures, steel structure accessories, greenhouses, feeding equipment, chicken houses, pig pens, arched buildings, granaries, silos, etc.

- Transportation and power industry: industrial HVAC, cooling towers, solar brackets, school bus decks, road sign posts, guardrail facades, coastal environments, cable trays, power transmission and distribution high and low voltage switch cabinets, box-type substation exteriors, etc.

Features of zam steel

- Superb corrosion resistance: 5-10 times more corrosion-resistant than ordinary galvanized steel, with self-repairing protection for cutting edges ((because of magnesium).

- Long service life: due to the super corrosion resistance of zam steel, its service life is more sustainable.

- Excellent machinability: zam steel is wear-resistant and scratch-resistant, and can adapt to various processing.

- Reduce costs: zam steel’s anti-rust ability can reach the standard of stainless steel, but the price is 40% cheaper than stainless steel.

- Self-repair ability: zam steel has unique characteristics and self-repair ability. When the coating is scratched or cut, the magnesium in zam steel can form an oxide film on the cross section, separating the coating from the external environment to prevent corrosion.

The role of each element in the zam steel coating

First, let’s introduce the main components of the coating in the zinc-aluminum-magnesium steel. The content of zinc 80%-90%, aluminum 5%-11%, magnesium 1%-3% and a small amount of silicon.

- The main function of zinc is to prevent steel from rusting.

- The role of magnesium is to improve corrosion resistance, because adding magnesium to the coating can reduce the surface tension of the coating and reduce the occurrence of leakage plating.

- The role of aluminum can enhance the corrosion resistance and heat resistance of steel.

- The small amount of silicon in zam steel is mainly to inhibit the reaction between aluminum and iron.

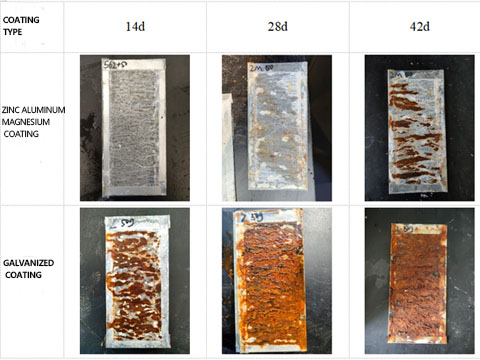

The performance of galvanized steel and zam steel in salt spray corrosion experiments is shown in the figure below:

ZAM Steel vs GI Steel vs GL Steel

| Comparison items | ZAM steel | GI steel | GL steel |

| Coating composition | Zn (80%-90%), aluminum (5%-11%), magnesium (1%-3%), forming Zn-Al-Zn₂Mg ternary eutectic structure | Pure zinc coating, Zn≥99% | 55% aluminum (Al), 43.4% zinc (Zn), 1.6% silicon (Si) |

| Corrosion resistance | Extremely strong, stronger than gl, with self-repair function, adaptable to high salt and high humidity environment | Medium, relies on zinc layer sacrificial anode protection, easy to corrode in harsh environment. | Good, 2-6 times that of GI steel, resistant to high temperature corrosion (stable below 315°C) |

| Processing performance | Excellent (180° bending without cracks) | Excellent (good ductility) | Good (aluminum layer is prone to cracking) |

| Classic applications | Strong corrosion environment such as coastal buildings, chemical plants, high humidity areas, photovoltaic brackets, marine engineering, etc. | General environment such as ordinary buildings (roofs, walls), furniture, pipes, etc. | Chemical equipment, high temperature furnaces, chimneys, oven parts, etc., where corrosion resistance and high temperature resistance are required |

| Price | Highest, due to complex process and superior performance | Minimum, mature production process, high cost performance | Medium, between ZAM steel and GI steel |

Our packing

Conclusion

Zinc aluminum-magnesium steel can be produced in a variety of forms, including steel coils, corrugated steel plates, perforated plates, steel pipes, etc., and has a wide range of applications. Different configurations have different uses. In the procurement process, it is necessary to communicate the use scenarios to ensure that the most suitable zam steel products are used.

Wanzhi Steel is a professional ZAM steel supplier in China, having passed multiple certifications including ISO 9001, CE, and Integrity Supplier. Our zinc-aluminum-magnesium production line has an annual output of 20w tons and can guarantee delivery time. Welcome to contact Wanzhi Steel for details about zam steel.