Stainless Steel Water Storage Tank

Our stainless steel water storage tanks are precision-manufactured from food-grade SUS304 or SUS316L stainless steel. They can be designed in various structural forms, including vertical, horizontal, square, and round, to meet different usage requirements.

- Plate thickness: 0.8mm – 3mm

- Capacity:300L – 100,000L+

- Material: SUS304 / SUS316L

Ensure product quality and transportation

Stainless steel water storage tanks are primarily used for storing various media such as clean water, hot water, neutral chemical liquids, and sterile water. Thanks to the corrosion resistance and structural stability of stainless steel, they are widely applicable to liquid storage needs in various scenarios, including civil, industrial, fire-fighting, and agricultural applications.

For more stainless steel tank products, please visit our official website for mechanical products: https://wz-mach.com/

Stainless Steel Water Storage Tank Specifications

| Product Name | Stainless Steel Water Storage Tank |

| Material | SUS304 / SUS316L |

| Sheet Thickness | 0.8mm – 3.0mm |

| Capacity | 300L – 100,000L+ |

| Type | Round, square, spherical |

| Installation Method | Vertical, horizontal |

| Interface Specifications | DN25 – DN200 |

| Pressure Bearing Capacity | Atmospheric pressure/pressure bearing type |

| Surface Treatment | 2B, mirror finish, matte finish |

Structure of Our SS Water Storage Tank

- Tank Body: Constructed from SUS304 or SUS316L stainless steel. All internal filtration sections feature smooth curved transitions. Interior surfaces undergo mirror polishing to meet sanitary standards.

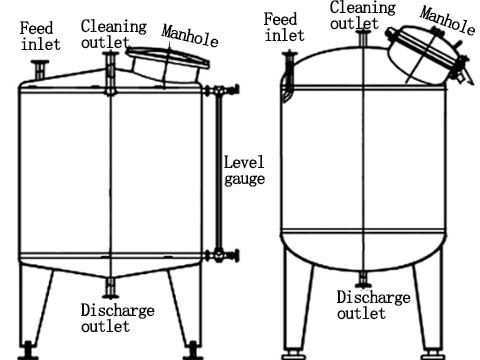

- Interface System: Includes inlet, outlet, overflow port, drain port, manhole, and level gauge connection.

- Standard Configuration: Includes sanitary manhole, CIP cleaning ball/spray ball, and level gauge.

- Customization Options: Tanks can be designed as single-walled, double-walled, or jacketed according to customer requirements. Available in vertical or horizontal configurations with shapes including cylindrical, square, spherical, and more.

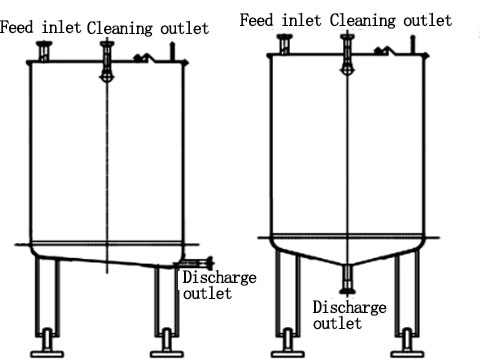

Stainless Steel Water Storage Tanks We Supply

- Top-opening with sloped bottom: The inclined base directs liquids and sediments to naturally flow toward the lowest drain outlet.

- Top-opening lid with conical bottom: The conical base provides optimal hydrodynamic discharge performance and high drainage efficiency.

- Top and bottom conical heads: This structure offers superior pressure resistance compared to flat lids, while the conical design facilitates fluid flow and complete drainage.

- Top and bottom elliptical heads: Elliptical heads distribute stress evenly, enabling them to withstand higher internal and external pressures. They represent a standardized pressure vessel construction method.

Product Advantages

- Hygienic Safety: Food-grade materials (SUS304/SUS316L) feature a dense, smooth stainless steel surface with no pores, inhibiting algae and bacterial growth for reliable safety.

- Customizable and Flexible: Dimensions, capacity, and interface specifications can be tailored to installation sites and liquid storage requirements, supporting vertical, horizontal, square, and circular configurations.

- Exceptional Durability: Easy to clean and maintain, with outstanding resistance to corrosion, oxidation, seismic activity, and wind. Offers lower overall long-term operating costs.

Stainless Steel Water Storage Tank Application

- Residential and Commercial: Drinking water, fire protection water reserves, and emergency backup tanks for homes/hotels/schools/hospitals; insulation storage tanks for solar/air-source hot water systems.

- Food and Beverage Industry: Production water reserves, raw liquid storage (syrups, juices), purified water storage, etc.

- Pharmaceutical and Biotech: Storage and distribution of pharmaceutical purified water, water for injection, and buffer solutions for bioreactor media.

- Agriculture and Environmental Protection: Rainwater harvesting and reuse systems; irrigation/aquaculture water reserves for farms; intermediate and clear water tanks in water treatment projects.

Tips for Selecting Stainless Steel Water Storage Tanks

1. Material and Manufacturing Process Selection

- Stainless Steel Material: For storing domestic water, food-grade 304 stainless steel is essential. Verify the product’s material quality certificate to prevent manufacturers from substituting it with 201 stainless steel.

- Welding Details: All internal welds must be TIG welded and mechanically or electrolytically polished to a mirror finish. This prevents microbial growth on rough weld scars.

- Sealing Structure: The lid-to-tank connection should feature embedded silicone gaskets to ensure airtightness, effectively blocking dust, insects, and contamination.

- Insulation Configuration: For applications requiring constant-temperature water storage, prioritize double-walled stainless steel tanks with polyurethane foam-filled jackets. These provide insulation lasting over 72 hours.

2. Structural Form and Pressure Rating

- Vertical vs. Horizontal Selection: Vertical tanks save floor space, ideal for compact areas; horizontal tanks offer low center of gravity and superior stability, facilitating low-level integration with horizontal piping systems.

- Pressure Rating: Atmospheric tanks feature vent holes at the top and are designed solely for static storage. For pressurized water storage, select appropriate pressure vessels based on specific requirements.

Why Choose Us

- The stainless steel water tanks we supply are made of food-grade SUS stainless steel plates, which are corrosion-resistant and not easy to breed antibacterial and algae.

- Precise cutting equipment, advanced stamping equipment, high strength of finished products, high pressure-bearing strength.

- Can store a variety of different solvents, such as some neutral chemical solvents.

We consistently prioritize three core principles: durability, compliance, and sustainability. We professionally develop, manufacture, and supply various stainless steel storage tanks. With stable quality and exceptional adaptability, we fully meet diverse liquid storage needs across multiple scenarios. Additionally, we offer highly flexible customization services, precisely producing tanks based on customer-provided specifications. For any requirements, please contact us.