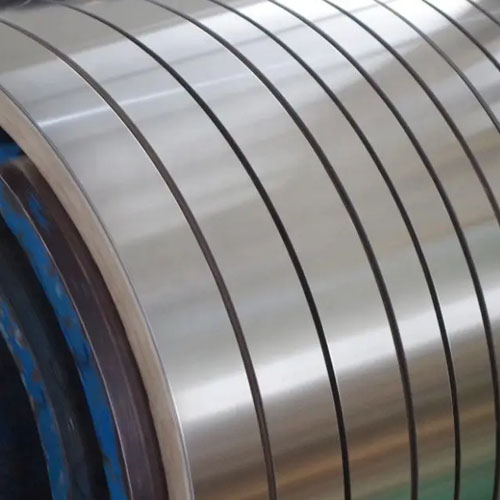

Stainless steel strips

Our stainless steel strips are made from high-quality raw materials with perfect strength and precision. Our stainless steel strip range includes a variety of sizes and surfaces, and is well-made to meet your various applications.

Thickness: 2-13mm

Width: <600mm

Surface treatment: 2B, 2D, BA, No.1, No.4, No.3, SB, HL, mirror, sandblasting, etc.

tag: Steel Strip

Ensure product quality and transportation

Wanzhi Steel can provide stainless steel strips of different sizes and various surface treatments. The spot inventory products include 304 stainless steel strip, 201 stainless steel coil, 316L stainless steel strip, 301 stainless steel coil and other precision strip steel strips.

Stainless steel strip specifications

| Product Name | Stainless steel strip |

| Thickness(mm) | 2mm – 13mm |

| Width(mm) | <600mm |

| Grade | 201, 202, 301, 304, 316, 310, 304L, 316L, 409L, 410S, 420, 430, 439, 441, etc. |

| Surface treatment | 2B, 2D, BA, No.1, No.4, No.3, SB, HL, mirror, sandblasting, etc. |

| Technology | Hot Rolled/Cold Rolled |

| Density | 7.93 g/cm³ |

| Packing | Standard Seaworthy Package or as required |

| Payment Terms | EXW,FOB,CIF,CFR etc. |

Stainless steel strip thickness allowable deviation (mm)

| Nominal thickness | Allowable deviation | Nominal thickness | Allowable deviation |

| >2~≤4 | ±0.17 | >6~≤8 | ±0.21 |

| >4~≤5 | ±0.18 | >8~≤10 | ±0.23 |

| >5~≤6 | ±0.2 | >10~≤13 | ±0.25 |

Allowable deviation of stainless steel strip width (mm)

| Nominal width | Allowable deviation | ||||

| thickness≤3 | 3<thickness≤5 | 5<thickness≤7 | 7<thickness≤8 | 8<thickness≤13 | |

| <250 | +0.5, 0 | +0.7, 0 | +0.8, 0 | +1.2, 0 | +1.8, 0 |

| ≥250~<600 | +0.6, 0 | +0.8, 0 | +1.0, 0 | +1.4, 0 | +2.0, 0 |

Stainless steel strip production video

Application of stainless steel strip

- Auto parts: windshield wipers, mufflers, spare parts, etc.

- Household items: tableware, water heaters, boilers, etc.

- Medical equipment: scalpels, injection needles, dental instruments, catheters and stents, etc.

- Food industry: cans, bottle caps, blenders, conveyor belts and storage tanks, etc.

- Watches: watch straps, watch cases, springs, etc.

- Glass manufacturing: used for glass annealing furnace mesh belts, baking furnace mesh belts, bottle conveyor mesh belts, mosaic mesh belts, etc.

- Machinery manufacturing: used for the manufacture of production equipment for chemicals, dyes, papermaking, oxalic acid, fertilizers, etc.

In addition to the above applications, stainless steel strips are also used to manufacture various types of metal hoses, heat treatment protective layers, various types of precision springs, etc.

Our ss strip Case

Purchase ss strip specification

- Thickness: 1.2mm, 1.5mm

- Width: 600mm

- Material: 304 Stainless Steel

- Surface: 2B

- Quantity: 1.2mm 25 tons, 1.5mm 25 tons

- Delivery Port: CIF Port of Klaipeda

Cold rolled ss strip VS hot rolled ss strip

Process

- Cold-rolled stainless steel uses hot-rolled stainless steel as a blank and is rolled through a cold rolling mill at room temperature. Deformation occurs by mechanical force below the recrystallization temperature of the metallic material.

- Hot-rolled stainless steel uses slabs as raw materials and is heated by rough rolling units and finishing rolling units. It is usually heated to above 1000℃ and rolled above the recrystallization temperature of the metal material.

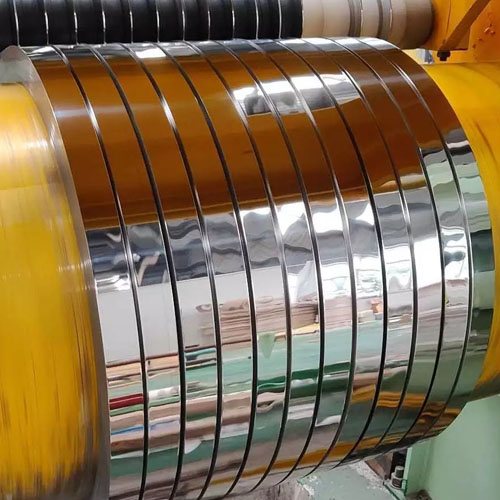

Appearance

- The surface of cold-rolled stainless steel strip is bright. Cold-rolled stainless steel is rolled multiple times, which significantly improves the surface quality.

- The hot-rolled stainless steel strip has a rough surface, oxide scale, and low smoothness.

Application

- Cold-rolled stainless steel strip has high strength, high hardness, high surface finish and high dimensional accuracy. Suitable for manufacturing precision parts and assemblies.

- Hot-rolled stainless steel strip has good plasticity and ductility and is suitable for manufacturing large parts and structural parts.

conclusion

We have very strict production requirements for stainless steel strips. They must absolutely comply with the allowable errors in manufacturing and rolling, and have complete sizes and high product precision. The stainless steel strips produced can perfectly meet customer requirements.

Our stainless steel products include stainless steel coils, stainless steel plates, stainless steel strips, 304 stainless steel, 316 stainless steel, 200 series stainless steel, etc. If you need to purchase stainless steel products, please feel free to contact us.