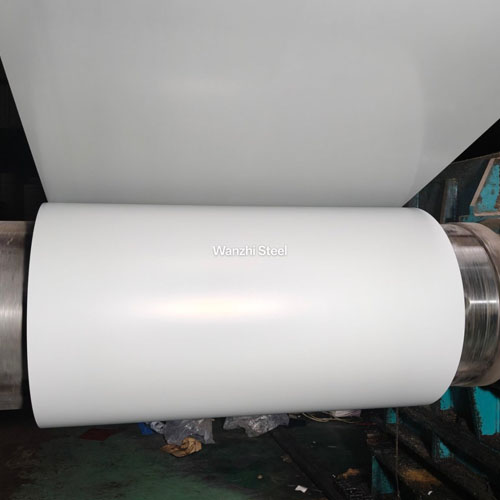

RAL 9002/9010 Prepainted Steel Coils

Wanzhi Steel’s RAL 9002/9010 pre-painted steel coils offer minimal color variation, strong corrosion resistance, and easy processing. RAL 9002/9010 is a commonly used color for white steel coils and is highly popular in the market.

Thickness: 0.2mm – 2mm

Width: 600mm – 1250mm

Roll Inner Diameter: 508mm (20 inches), 610mm (24 inches)

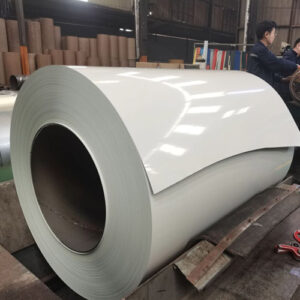

Ensure product quality and transportation

RAL 9002/9010 pre-painted steel coils combine excellent corrosion and weathering resistance, beautiful decorative properties, and excellent processing properties, making them an ideal material for extending service life and enhancing aesthetics.

Specification

| Product Name | RAL 9002/9010 Prepainted White Steel Coils |

| Thickness | 0.2mm – 2mm |

| Width | 600mm – 1250mm |

| Roll Inner Diameter | 508mm (20 inches), 610mm (24 inches) |

| Roll Weight | 3 tons – 8 tons |

| Color | RAL 9002, RAL 9010 |

| Substrate Types | DX51D, DX52D, DX53D, SPCC, SGCC, CGCC, Q195, Q235 |

| Standards | GB, JIS, EN, ASTM |

| Surface Treatment | Lamination, embossing, printing, etc. |

| Processing Services | Profiling, punching, cutting, slitting, etc. |

| MOQ | 5 tons |

| Packaging | Standard export package or as per your requirements |

Ral9002/9010 pre-painted steel coil substrate material & application

| Substrate Type | Grade | Product Name | Core Features | Recommended Applications |

| Galvanized Steel | GI(DX51D+Z/DX52D+Z) | PPGI Coil | Cathodic protection: Zinc sacrifices itself to protect the steel base. Highly cost-effective and easy to work with. | Inland general industrial and commercial buildings. This is one of the most popular choices in the market. |

| Galvalume Steel | AZ(DX51D+AZ) | PPGL Coil | Barrier + Cathodic Protection: 55% aluminum, 43.4% zinc, 1.6% silicon. Corrosion resistance is 2-6 times that of GI, with excellent high-temperature resistance. | Coastal, high-humidity, industrially polluted areas, and projects requiring higher corrosion resistance. |

| ZAM Steel | ZM(Zinc-Aluminum-Magnesium) | ZAM-based color-coated steel | Extreme Corrosion Protection: A new coating offers 10-20 times the corrosion resistance of GI and self-healing properties. | High-end buildings, harsh corrosive environments (chemical plants, coastal frontiers), and partial stainless steel replacements. |

| Cold-rolled steel | SPCC | Cold-rolled color-coated steel | Low-carbon cold-rolled steel, with exceptional surface flatness, excellent workability (easy to stamp and bend), and low cost. | Indoor ceiling decoration (primarily Ral 9010), furniture panels, and internal structural components of home appliances (where exposed rust protection is not required). |

RAL 9002 vs RAL9010

| Features | RAL 9002 (off-white) | RAL 9010 (Pure White) |

| Visual Effect | Soft, warm, elegant, and non-staining. | Bright, clean, modern, and eye-catching. |

| Stain Resistance | Excellent: dust and minor stains are less noticeable. | Generally, stains, rain marks, and dust are more noticeable. |

| Light and Heat Reflection | Medium: provides some thermal insulation. | Extremely high solar reflectivity, contributing to energy savings. |

| Weather Resistance | Good color stability with the same coating, with minor discoloration being unnoticeable. | Under the same coating, slight yellowing may occur after long-term use due to UV exposure. |

| Applicable Coatings | Suitable for PE, SMP, HDP, and PVDF. | PE, SMP, HDP, and PVDF are all acceptable (HDP or PVDF coatings effectively slow yellowing). |

| Suggested Applications | Suitable for industrial plants, logistics warehouses, and low-profile commercial buildings. | Suitable for high-end commercial buildings, public buildings, cool roofs, and interior decoration. |

Packaging

Why Choose Us

- Colors are based on standard RAL color numbers, ensuring accurate and consistent color without batch-to-batch color variations.

- The combination of base materials (such as GI, GL) and topcoats (such as HDP and PVDF) provides excellent corrosion and UV resistance, ensuring a long service life.

- Using advanced production equipment and processes, our factory-applied coating ensures stable product quality and performance, as well as high production efficiency.

- We have our own testing center, which inspects our products for corrosion resistance, weather resistance, physical properties, and specifications to ensure quality assurance.

Wanzhi Steel is a professional color-coated steel manufacturer in China. We can customize colors and provide free samples. If you require color-coated steel, please feel free to contact us.