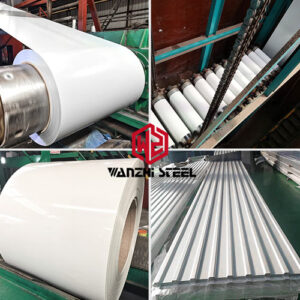

RAL 7016 PPGI PPGL

Wanzhi Steel produces RAL 7016 color coated steel coils mainly including RAL 7016 PPGI and RAL 7016 PPGL, which have authentic color and small dimensional error, and can provide processing services such as longitudinal shearing, cutting, and profiling.

Thickness: 0.12-1.5mm

Width: 600-1250mm

Paint type: PE, SMP, PVDF, HDP

Ensure product quality and transportation

RAL 7016 is a classic grey (coal grey), this color is visually robust, modern and resistant to dirt, as the color of color coated steel coils, it is often used in building facades, appliance housings, industrial equipment and other scenarios.

Specifications

| Product name | RAL 7016 PPGI PPGL |

| Thickness | 0.12-1.5mm |

| Width | 600-1250mm |

| Paint type | PE, SMP, PVDF, HDP |

| Paint thickness | 20-25μm on the front, 7-15μm on the back |

| Inner diameter | 508mm / 610mm |

| Coil weight | 3 – 10 tons (customizable) |

| Substrate type | GI, GL |

| Substrate coating | Z30-Z275g/m², AZ30-AZ150g/m² |

| Material | DX51D, DX52D, DX53D, SPCC, SPCD, SGLCC, SGLCH, ETC |

| Yield strength | 250 – 550MPa |

| Tensile strength | 270 – 650MPa |

| Elongation | ≥18% |

| Standard | ASTM, EN, GB, JIS |

| Processing Services | Bending, slitting, cutting, punching, profiling, etc. |

| MOQ | 5 tons |

| Packaging | Standard export package or as per your requirements |

Substrate Comparison (PPGI vs PPGL)

| Substrate type | Galvanized Coil (GI Coil) | Galvalume Coil (GL Coil) |

| Coating composition | Pure zinc (Zn ≥99%) | 55% aluminum + 43.5% zinc + 1.6% silicon |

| Coating weight | 30-275g/m² | 30-150g/m² |

| Corrosion resistance | Good (suitable for general environment) | Excellent (salt spray resistance, weather resistance) |

| Heat resistance | Generally, long-term use temperature is recommended to be ≤100℃ | Excellent (≤315℃) |

| Typical applications | Building inner panels, home appliance shells, light structural parts, etc. | Coastal buildings, building exterior panels, chimneys, ovens, high-temperature pipes, etc. |

Production Video

RAL 7016 PPGI PPGL Application Scenarios

- Construction field: interior decoration, metal roofing, partition wall, curtain wall, industrial plant, temporary building, photovoltaic support, etc.

- Home appliance manufacturing: refrigerator/washing machine/air conditioner shell, high-end home appliances, outdoor appliance box, oven liner, etc.

- Transportation: interior of carriages, interior of cargo containers, exterior of containers, highway guardrail, bus stops, etc.

- Industrial equipment: for control cabinets, electrical boxes, metal cabinets and other industrial equipment shells

- Other applications: office furniture, filing cabinets, shelves, display racks, industrial chimneys, etc.

RAL 7016 PPGI PPGL Advantages

- Excellent corrosion resistance: The surface anti-corrosion plating and paint coating provide double protection and stronger corrosion resistance.

- Strong decorative effect: RAL 7016 is a neutral color, suitable for modern buildings and enhances the texture.

- High temperature resistance: all have a certain degree of high temperature resistance, PPGL is more resistant to high temperature.

Notes on Purchase

- Confirm the substrate: PPGL is recommended for coastal areas, and PPGL+PVDF is recommended for outdoor use.

- Coating system: PVDF coating is recommended for outdoor use, and polyester (PE) is sufficient for indoor use.

- Substrate performance: Focus on the yield strength, T-bend test and coating adhesion (cross-cut method ≥ 0 level) of the substrate to ensure that there is no cracking during processing.

Summary: PPGI has a lower cost and is suitable for ordinary environments; PPGL has stronger corrosion resistance and is suitable for harsh environments. When purchasing, you need to pay attention to technical parameters such as substrate type, coating system, zinc layer weight, etc. to ensure that the product meets the requirements. You can also contact us for product purchase recommendations.

Why Choose Us?

- Our colors have almost no color difference, and we provide customers with RAL color cards and actual product comparison videos. Customers can also inspect the products on site to ensure that the product colors are accurate.

- With several production lines, including gi steel, gl steel, zam steel, color coated steel and other production lines, there is a complete supply chain to ensure both quality and competitive price.

- With 17+ years of production experience and 14+ years of export experience, we offer the most cost-effective solutions for your projects.

- Slitting, cutting, and profiling equipment is available for a wide range of types, including but not limited to:

Wanzhi Steel is certified by ISO 9001, ISO 14001 and other certificates, and has sufficient production capacity and stable performance by virtue of advanced production lines and professional technicians. If you are interested in color coated steel products, please feel free to contact us.