Prepainted Steel Sheets

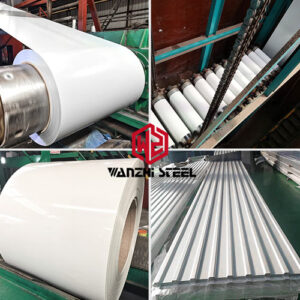

Wanzhi Steel supplies PPGI and PPGL steel sheets with paint coatings in PE/HDP/SMP/PVDF. Available in a wide range of colors, these sheets offer excellent weather resistance and extended service life. Custom colors can be produced based on provided samples.

- Factory address: Shandong, China

- Thickness: 0.12 – 1.2mm or as required

- Width: 600 – 1250mm or as required

- Paint Type: PE, SMP, HDP, PVDF

tag: PPGI

Ensure product quality and transportation

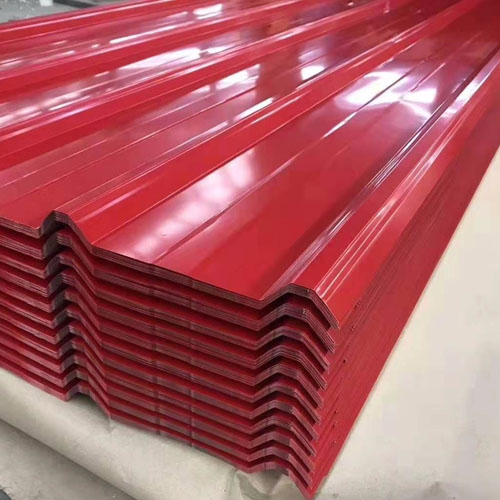

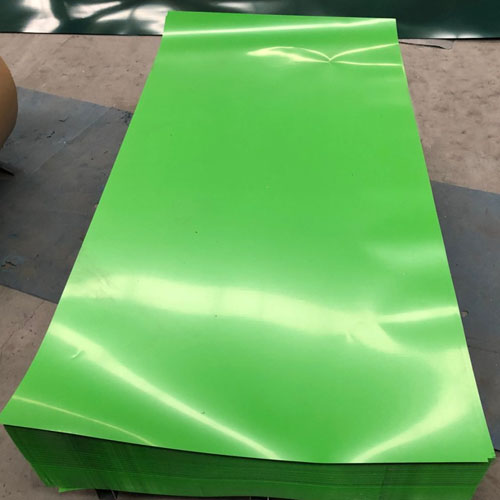

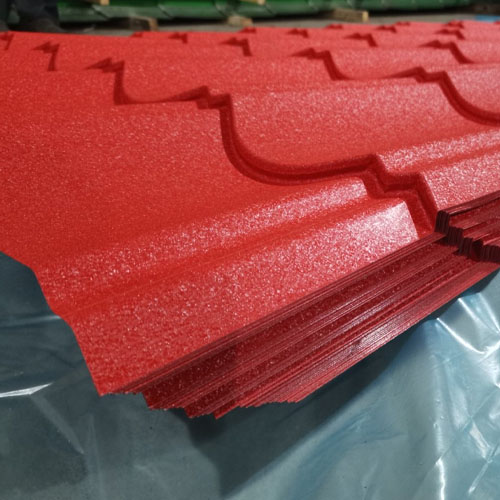

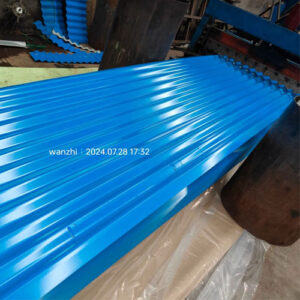

Pre-painted steel sheets include both flat sheets and corrugated sheets, both manufactured from pre-painted steel coils through various processing methods. Their surfaces are coated with paint in different colors, offering features such as strong corrosion resistance, high strength, and excellent decorative properties.

Our pre-painted steel sheet colors are typically based on the RAL color chart. Please visit the RAL color chart. If you require custom colors, you may mail us your sample, and we will customize the color according to your sample.

Specifications and dimensions

| Product Name | Prepainted Steel Sheets |

| Thickness | 0.12 – 2.mm |

| Width | 600 – 1250mm |

| Base metal | Galvanized steel, Galvalume steel, etc. |

| Colors | As per RAL Color (custom patterns are available) |

| Paints | PE, SMP, HDP, PVDF |

| Paint thickness | Top: 11-35μm Back: 5-14μm |

| Value-added Services | Cutting to length, shearing, profiling, etc. |

| Application | Advertising, Construction, Home appliance, Road fence, Auto industry, etc. |

| Delivery Time | 15-25 working days after payment |

| Grade | DX51D, DX52D, DX53D, SPCC, SGCC, A653, S350GD, S550GD,ETC |

| Standard | ASTM, EN, DIN, GB, JIS |

| Certificate | ISO 9001, ISO 14001, CE, SGS |

| MOQ | 10 tons |

| Package | Standard Export Package |

Product Video

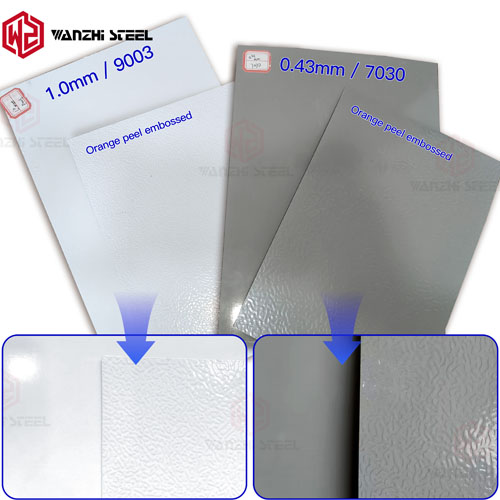

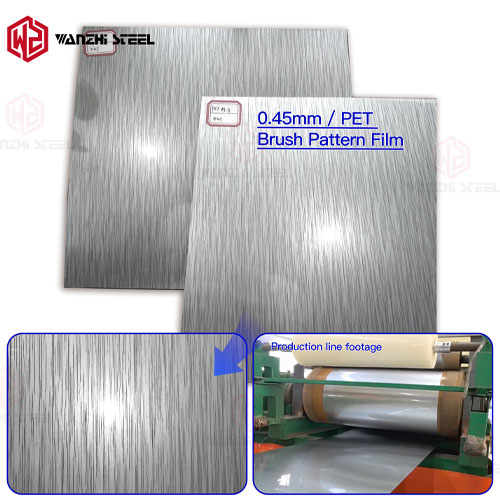

What surface textures can we provide

- High-gloss surface: Features high surface gloss with rich, vibrant color.

- Matte surface: Low gloss level with minimal reflection.

- Frosted surface: Exhibits a uniform, fine-grained texture.

- Orange peel surface: Presents a subtle, uneven texture resembling orange peel.

- Embossed surface: Creates three-dimensional geometric patterns through mechanical embossing on the substrate.

- Printed Patterns: Surface designs include wood grain, stone texture, brick pattern, floral motifs, etc.

- Laminated Film-Coated sheets: A layer of polymer film (e.g., PVC, PET, or PETG) is laminated onto the surface to provide exceptional scratch resistance and chemical corrosion resistance.

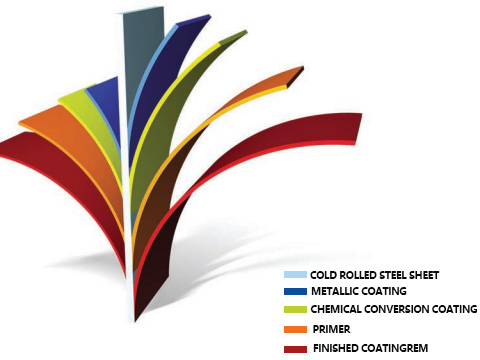

Prepainted steel sheet coating structure type

1. Coating structure type

- 2/1: The upper surface is coated twice, the lower surface is coated once, and baked twice.

- 2/1M: Coat the upper and lower surfaces twice, and bake twice.

- 2/2: Coat the upper and lower surfaces twice, and bake twice.

2. Uses of different coating structures

- 2/1: The corrosion resistance and scratch resistance of the single-layer back paint are poor, but it has good adhesion and is mainly used in sandwich panels;

- 2/1M: The corrosion resistance, scratch resistance and processing formability of the back paint are good, and it has good adhesion, which is suitable for single-layer profiled panels and sandwich panels.

- 2/2: The corrosion resistance, scratch resistance and processing formability of the double-layer back paint are good, and most of them are used for single-layer profiled panels, but its adhesion is poor and it is not suitable for sandwich panels.

Application of Prepainted Steel Sheet

- Outdoor: factory buildings, agricultural warehouses, residential prefabricated components, corrugated roofs, walls, rainwater pipes, balconies, kiosks, rolling doors, etc.

- Indoor: doors, door frames, light steel structures of houses, screens, ceilings, elevators, stairs, ventilation ducts, etc.

- Electrical appliances: refrigerators, washing machines, switch cabinets, air conditioners, microwave ovens, bread machines, etc.

- Furniture: radiators, lampshades, wardrobes, tables, lockers, bookshelves, etc.

- Transportation industry: automobiles, train interior decoration, containers, fences, ship bulkheads, etc.

- Others: writing panels, garbage cans, billboards, clocks, typewriters, dashboards, weighing machines, photographic equipment, etc.

Packaging Details

FAQ about Prepainted Steel Sheet

How to choose Prepainted Steel Sheets

- The first thing to consider when choosing prepainted steel sheets is where they will be used? Because the substrate, color, and coating required for different uses will be different.

- The second thing to consider is the use environment. Different use environments will have different service lives for prepainted steel sheets.

How to choose a supplier of Prepainted Steel Sheets

- Choose manufacturers that value product quality. It is difficult for low-priced manufacturers to meet product quality standards;

- Before purchasing, confirm the quality standards in advance. If conditions permit, you can go to the factory for on-site inspection.

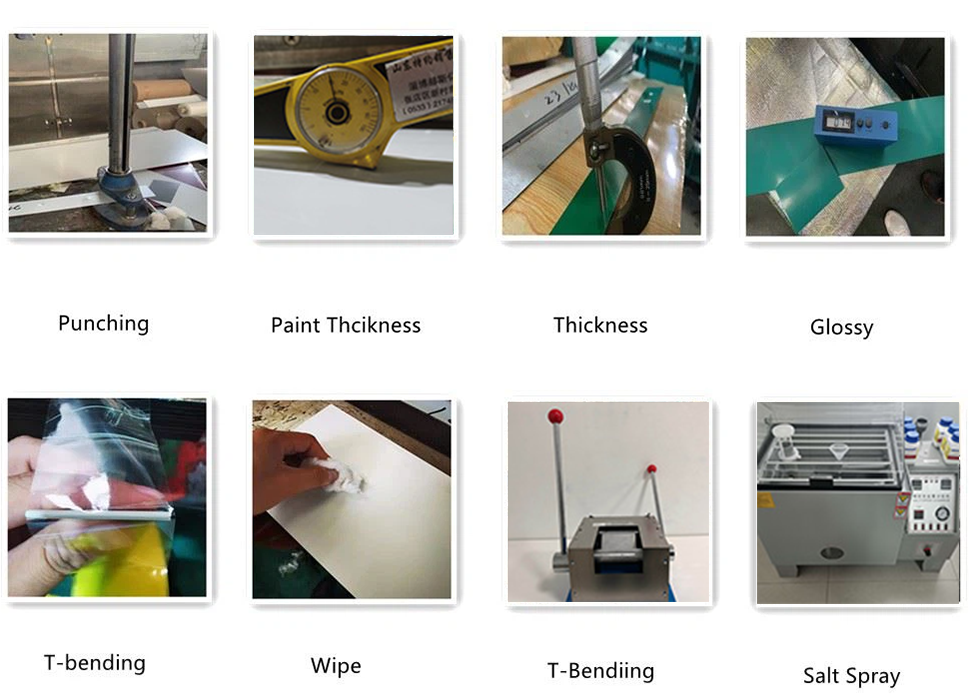

What tests will Wanzhi prepainted steel sheets undergo before leaving the factory?

The pre-coated steel plates produced by Wanzhi Steel will undergo a variety of tests before leaving the factory: coating thickness test, corrosion resistance test, weather resistance test, flexibility test, physical property test (yield strength, tensile strength, elongation), zinc layer thickness test, etc.

Why Choose Us?

Product Advantages

- Extensive Product Range: We offer a wide array of colors and support multiple surface finishes. Combined with value-added services like custom cutting, shearing, and forming, we supply diverse product types to meet all decorative needs.

- Premium Substrates + High-Performance Coatings: Utilizing high-quality substrates (cold-rolled steel coils, galvanized steel coils, or aluzinc steel coils), we employ advanced production techniques paired with mainstream high-performance coatings like PE, SMP, HDP, and PVDF. These coatings deliver strong adhesion and excellent weather resistance.

- Stringent Quality Management: Rigorous product inspection protocols cover not only raw materials but also the entire production process under dedicated supervision. Finished products undergo strict testing for corrosion resistance, weatherability, mechanical properties, and dimensional accuracy, with full support for third-party inspections.

Company Strengths

- Production Capabilities: The company operates three pre-painted coil production lines, capable of fulfilling large-volume orders (refer to the 1,200-ton PPGL case). However, we also accommodate small-batch orders (MOQ: 10 tons). Our mature supply chain management ensures delivery within 10-30 business days after payment.

- Integrity in Business: We hold multiple international certifications including ISO 9001, ISO 14001, CE, and Trusted Supplier. We consistently operate with integrity, delivering products exactly as specified in contracts and strictly prohibiting any cutting corners.

- Professional Team: Our experienced technical sales and service team deeply understands your requirements. Based on your application scenarios, processing methods, and budget, we provide expert material selection advice and customized solutions.

As a specialized manufacturer of color-coated steel products, Wanzhi Steel has deepened its expertise in the steel industry for over 14 years. We engage with our clients through integrity and professionalism, earning the trust of loyal customers across multiple countries, including Russia, Libya, Brazil, Lebanon, Indonesia, Spain, and Saudi Arabia. If you are interested in color-coated steel products, please feel free to contact us anytime.