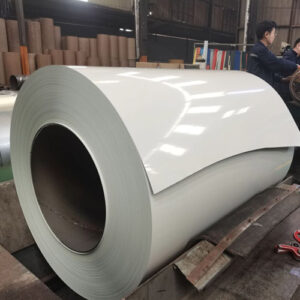

Powder-Coated Color Steel Coil

We are a professional supplier of powder-coated color steel coils, utilizing advanced electrostatic spraying technology. Our coatings deliver exceptional adhesion, color retention, and hardness, resulting in highly durable finished products.

Thickness: 0.12mm – 2.0mm

Width: 600mm – 1250mm

Powder Coating Thickness: 25μm – 120μm

Ensure product quality and transportation

We employ advanced continuous coil coating technology to seamlessly integrate premium metal substrates with durable, aesthetically pleasing powder coatings, delivering products that far surpass traditional pre-painted finishes.Offering exceptional durability, rich color textures, and eco-friendly advantages, our solutions are specifically designed for architecture, home appliances, and home furnishings, with customization available.

Specifications

| Product Name | Powder-Coated Color Steel Coil |

| Thickness | 0.12mm – 2.0mm |

| Width | 600mm – 1250mm |

| Length | Cut to size |

| Substrate | Cold-rolled steel coils, gi steel coils, and gl steel coils |

| Powder Coating Thickness | 25μm – 120μm |

| Color | Full RAL color range |

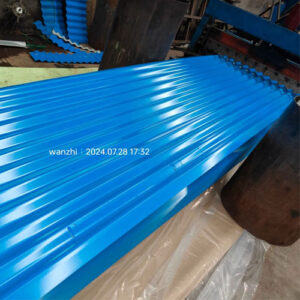

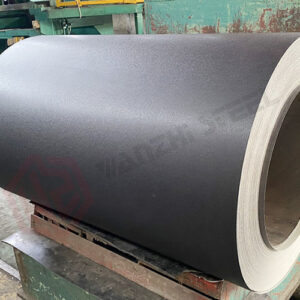

| Surface | High-gloss, matte, textured, sand-textured, wood-grain, stone-textured, orange peel texture, etc. |

| Processing Services | Bending, stamping, slitting, cutting, profiling, punching, etc. |

| MOQ | 5 tons |

| Packaging | Vertical/horizontal packaging for steel coils, conventional export packaging for steel sheets |

Production Video

Powder Coated Steel Production Process

Raw Material Pretreatment

High-quality cold-rolled steel coils or hot-dip galvanized steel coils are selected as substrates. These undergo multi-step processing including degreasing, water washing, acid pickling for rust removal, and phosphating/passivation to ensure coating adhesion.

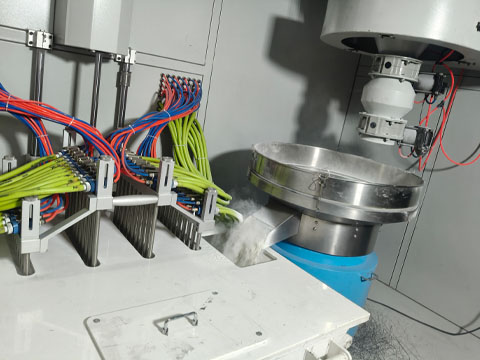

Electrostatic Powder Coating

Fully automated electrostatic spraying equipment evenly deposits solid powder onto the substrate surface under an electric field, ensuring no missed spots or sagging for 360-degree coverage without blind spots.

High-Temperature Curing

Coated coils enter an intelligent temperature-controlled curing oven. Baked for 15-20 minutes at a constant temperature, the powder coating fully melts, cross-links, and cures to form a dense, uniform protective layer. This enhances the coating’s impact resistance and chemical corrosion resistance.

Finished Product Inspection & Cutting

After passing rigorous tests including cross-cut testing, drop hammer impact testing, and salt spray resistance testing, products are precisely cut to customer specifications, ensuring every coil meets delivery standards.

Advantages of Powder-Coated Color Steel Coils

- Superior Protective Performance: Electrostatic spraying combined with high-temperature curing creates a thick coating layer, delivering exceptional corrosion resistance, excellent impact resistance, and long-lasting color retention for outdoor applications.

- Significant Environmental Benefits: Zero solvent volatilization during production, no VOC emissions, over 95% powder utilization rate with recyclability, meeting the most stringent environmental standards.

- Exceptional Decorative Appeal: Supports full RAL color spectrum production with diverse finishes including high-gloss, matte, textured, sand-grain, wood-grain, and stone-grain effects.

- Superior Processability: Strong adhesion between coating and substrate prevents cracking or peeling during bending, stamping, shearing, and other processing operations.

Powder-Coated Color Steel Coils Applications

- Architecture & Curtain Walls: High-end commercial building facades, metal roofing, airports, stations, and stadiums.

- Home Appliance Manufacturing: Panels and internal structural components for premium refrigerators, air conditioners, washing machines, and other appliances.

- Home Furnishings & Interior Design: Integrated wall panels, cabinet fronts, metal furniture, decorative partitions.

- Industrial & Transportation: Cleanrooms, sound barriers, automotive components, logistics equipment housings.

- Specialized Environments: Offshore engineering accessories, chemical plant enclosures, food processing partitions.

Powder-Coated Color Steel Coils vs. Pre-Painted Color Steel Coils

| Comparison Items | Powder-Coated Color Steel Coils | Pre-painted Color Steel Coils |

| Production Process Core | Utilizing electrostatic spraying technology, solid powder coatings are uniformly deposited onto steel surfaces before high-temperature curing. | Utilizing a continuous roll-coating process, paint coatings are applied to the steel coil surface via roller coating and cured at high temperatures to form a protective layer. |

| Coating Performance | The coating exhibits uniform thickness (typically 25-120μm), strong adhesion, excellent impact resistance, and outstanding weather resistance. | The coating is relatively thin, with a smooth and flat surface. It exhibits vibrant color initially but may fade over extended use. PVDF paint offers the best weather resistance. |

| Environmental Protection and Safety | Environmentally friendly, No solvent emissions during production, odorless after curing, and free of harmful heavy metals. | Environmental considerations require attention, as traditional liquid coatings may contain solvents, posing risks of VOC emissions and odor. |

| Design Flexibility | Highly customizable, Flexible color and texture options tailored to final requirements, ideal for small-batch and personalized orders. | Flexibility is limited; colors and patterns must be finalized before production, making it suitable for high-volume, standardized products. |

| Cost and Maintenance | Superior overall performance: While initial costs may be slightly higher, the extended lifespan and low maintenance requirements result in a more favorable total cost of ownership over the product’s lifetime. | High initial cost-effectiveness with exceptional production efficiency, ideal for large-scale, fast-delivery standard projects. |

Why Choose Us?

- Technological Leadership: We operate China’s leading coil powder coating production lines, featuring high process stability and production efficiency to fulfill large-volume orders with rapid delivery.

- Rigorous Inspection Processes: Our dedicated testing center implements strict quality control procedures to ensure every batch meets customer specifications, with third-party inspection support available.

- Trusted Supplier: Certified under ISO 9001, ISO 14001, and recognized as a Trusted Supplier, we maintain global credibility.

As a specialized coated steel manufacturer in China with over 14 years of production experience, we export to more than 100 countries and receive global acclaim for our products. Our coated steel offerings include:

Should you have any requirements for coated steel, please feel free to contact us.