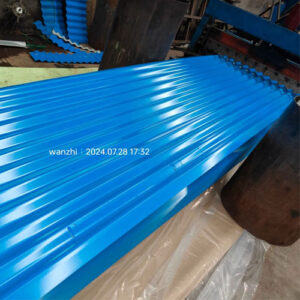

PCM Sheet

The PCM coils/sheets produced by Wanzhi Steel have rich colors and patterns, complete specifications, strong corrosion resistance, and price advantages. If you need pre-coated metal sheets for home appliances, please contact us.

Substrate thickness:Steel( 0.2mm – 1.2mm);Aluminum( 0.3mm – 1.5mm)

Width: 600mm – 1250mm

Length: Cut as required

Coating type: PE, SMP, HDP, PVDF

Ensure product quality and transportation

PCM sheet (Pre-painted Metal Sheet) is a metal material commonly used in home appliances. It is made by coating an organic coating on the metal surface and curing it at high temperature. It has the characteristics of strong corrosion resistance, strong decorativeness, and durability, and is widely used.

PCM Specifications

| Product name | PCM Coil / Sheet |

| Metal sheet thickness | Steel: 0.2mm – 1.2mm |

| Aluminum: 0.3mm – 1.5mm | |

| Width | 600mm – 1250mm |

| Length | Cut as required |

| Substrate type | Cold rolled steel, galvanized steel, aluminum |

| Coating type | PE, SMP, HDP, PVDF |

| Color | According to RAL color card |

| Functional coating | Antibacterial coating, self-cleaning coating, fingerprint-resistant coating |

| Surface Type | Matte, high-gloss, fine grain, orange peel, stone grain, printed patterns, etc. |

| Processing Service | Slitting, cutting, profiling, etc. |

| MOQ | 10 tons |

| Packaging | Standard export package or as per your requirements |

PCM Sheet Advantages

- Strong corrosion resistance: Multi-layer coating (primer + topcoat + varnish) can effectively prevent the metal substrate from contacting with air, moisture, etc., and has strong corrosion resistance.

- Strong decorative effect: The coating is rich in color and uniform in color. It can be made into various patterns, textures and other effects through special processes to enhance the appearance of home appliances.

- Low cost: More economical than stainless steel, VCM and other materials, suitable for mass production, reducing the manufacturing cost of home appliances.

- Good processing performance: PCM substrate has good ductility and can be processed by stamping, bending and other processes to meet various processing needs.

- Easy to clean: The coating surface is smooth and not easy to be stained with dust, oil and other stains. Daily cleaning is simple and efficient.

PCM Application Scenarios

- Large appliances: refrigerator door panels, side panels, and top covers; washing machine shells and control panels; air conditioner indoor and outdoor unit shells; microwave oven/oven shells, etc.

- Kitchen appliances: range hood panels; induction cooker top panels; rice cooker/water dispenser shells, etc.

- Small appliances: electric fan grilles and bases; air purifier/microwave oven/oven shells; heater panels, etc.

- Commercial appliances: commercial refrigerator/freezer door bodies; vending machine exterior parts, etc.<

PCM Sheet vs VCM Sheet

- Essential difference: PCM Sheet is a pre-painted metal sheet; VCM Sheet is a metal laminated sheet.

- Price comparison: PCM sheet is cheaper; VCM sheet is more expensive.

- Appearance comparison: PCM sheet is rich in color, single color effect, and mainly metallic texture; the surface is covered with PVC/PET film, with various patterns and smooth surface.

- Production cycle: PCM sheet has high production efficiency and short production cycle; VCM sheet has a relatively slow production cycle because it needs to be laminated.

Why Choose Us?

- The company has passed ISO 9001, ISO 14001 and other certifications, and is a representative of China’s honest suppliers, exporting to more than 120 countries.

- With 2 pre-painting and 2 printing production lines, it can produce PCM coils in various colors and patterns.

- The inspection process is strict, including salt spray test, bending test, coating adhesion, hardness and other aspects, and supports third-party inspection.

- PCM products are complete in specifications, and can provide plates, strips, corrugated plates, etc. with slitting, cutting, profiling and other equipment.

If your project requires PCM board, please contact us.