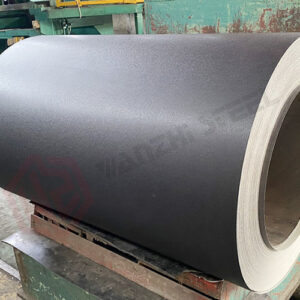

Orange Peel Textured Color Steel Coil

Orange Peel Textured Prepainted Steel Coil features a distinctive appearance, high functionality, and exceptional durability. Our PPGI/PPGL products offer a rich color palette, advanced manufacturing techniques, and extended service life.

Ensure product quality and transportation

Orange Peel Textured Prepainted Steel Coil is produced by applying a specialized coating formulation to the surface of hot-dip galvanized (GI) or galvanized aluminum-zinc (GL/Aluzinc) substrates, followed by embossing/ baking process to create a fine, uniform, matte texture resembling citrus peel. This results in a prepainted steel coil that combines functionality with aesthetic appeal.

Specifications

| Product Name | Orange Peel Textured Color Steel Coil |

| Thickness | 0.3mm – 1.5mm |

| Width | 1000mm, 1200, 1220, 1250mm (can be cut to length into strips, narrow rolls) |

| Length | Custom sheet length |

| Substrate Type | GI steel, GL steel |

| Coating | Z: 30-275g/m²; AZ: 30-150g/m² |

| Substrate Material | DX5ID, DX52D, DX53D, S250GD, S350GD, S550GD, SPCC, SGCC, A653, etc. |

| Standard | GB, EN, JIS, ASTM, DIN |

| Paint type | PE, SMP, HDP, PVDF |

| Coating structure | 2/1 (two coatings, one baking), 2/2 (two coatings, two baking) |

| Coil weight | 3-8 tons/roll |

| MOQ | 10 tons |

| Packaging | Standard export packaging (plastic film, moisture-proof paper, and galvanized iron sheet) |

Production Process

Substrate → Pre-treatment (cleaning, passivation) → Primer coating → Texture forming → Precision baking curing → Post-treatment (cooling, film covering) → Finished Product.

- Substrate Pre-treatment: Select premium substrates, undergo degreasing, water rinsing, phosphating/chromating conversion treatment to enhance coating adhesion;

- Primer Application + Curing: Roll-apply epoxy/polyurethane primer, cure via high-temperature baking at approximately 200°C to provide foundational corrosion protection;

- Orange Peel Texture Formation: Two methods exist—formulation-based (adding special rheology modifiers to topcoat, which naturally contracts during baking to form texture) or embossing roll method (pressing with precision orange peel rollers during semi-cured topcoat stage, followed by secondary baking after setting);

- Topcoat/Backcoat Application + Curing: Apply topcoat/backcoat and cure again at high temperature.

- Final cooling, slitting, winding, and packaging. Includes moisture-proof paper and steel band strapping to prevent transport scratches.

Features of Pre-painted Steel Coils with Orange Peel Texture

- Corrosion Resistance & Durability: The substrate offers inherent corrosion resistance, enhanced further by the paint coating. The orange peel texture surface provides greater durability compared to smooth surfaces.

- Highly Practical: The raised surface provides flaw concealment, abrasion resistance, scratch resistance, stain resistance, self-cleaning properties, and excellent slip resistance.

- Optical and Acoustic Optimization: The matte surface reduces glare, while the texture provides mild sound wave attenuation, improving indoor acoustic environments.

- Processing and Installation Friendliness: Suitable for cutting, bending, stamping, and roll forming, adapting to diverse building and equipment enclosures.

Applications of Orange Peel Textured Color Steel Coils

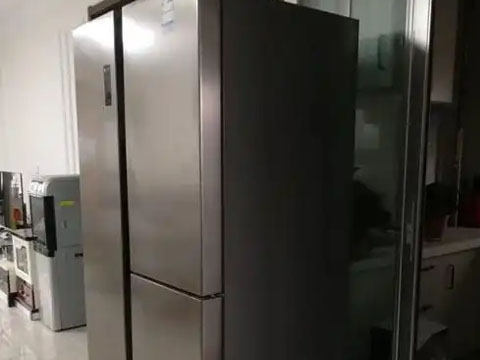

- Home Appliances & Equipment (Primary Applications): Refrigerator and washing machine shells, oven panels, or custom cabinet exteriors; protective panels for equipment, control cabinets, etc.

- Architecture: Roofing/wall cladding for museums, libraries, airports, commercial complexes; prefabricated housing/container side panels.

- Specialized Industrial Buildings: Cleanroom facilities, warehousing/logistics centers.

- Interior Decoration: Ceilings, partitions, accent walls in retail spaces and offices.

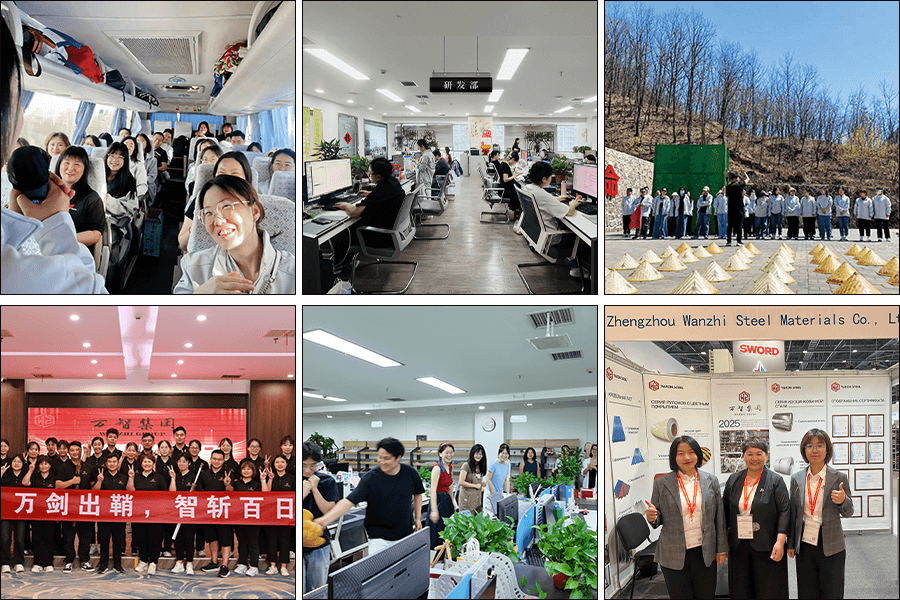

Why Choose Us

- We operate advanced pre-painted steel coil production lines and specialized processing equipment, supplying a diverse range of embossed steel products.

- Our products hold multiple certifications including ISO 9001, ISO 14001, CE, and SGS, and our company is a certified trustworthy supplier.

- The entire production process is monitored, with real-time video and image updates on production progress ensuring customers see tangible products.

- Our in-house testing center implements rigorous inspection protocols covering dimensional accuracy, corrosion resistance, mechanical properties, and more.

Wanzhi Steel specializes in supplying steel materials for home appliances. Our product range includes not only orange peel patterned color-coated steel coils but also laminated film metal coils (pearlescent, brushed, wood grain finishes, etc.) and PCM steel coils. For any home appliance steel requirements, please feel free to contact us.