Laminated PET/PVC Film Metal Coil

Laminated PET/PVC film metal coil is an innovative metal material featuring a rich and attractive appearance with a long service life, making it a highly valuable investment material.

Substrate Thickness: 0.3mm – 2.0mm

Substrate Width: 600mm – 1250mm

PET Film Thickness: 25μm – 100μm

PVC Film Thickness: 80μm – 300μm

Ensure product quality and transportation

Unlike roll coating for color steel coils, laminated film metal coils involve directly bonding pre-made decorative films to steel coils. This process fundamentally eliminates common coating defects such as color variation, orange peel, and sagging. Regardless of order volume, we guarantee exceptional consistency in color and texture.

Specification

| Product Name | Laminated PET/PVC Film Metal Coil |

| Substrate Thickness | Cold-Rolled Steel Coil: 0.3mm – 1.5mm |

| GI Coil: 0.3mm – 1.5mm | |

| GL Coil: 0.3mm – 1.2mm | |

| Aluminum Coil: 0.4mm – 2.00mm | |

| Substrate Width | 600mm – 1250mm |

| Substrates | Cold-Rolled Steel,GI Steel, GL Steel, Aluminum, Stainless Steel |

| Film Colors | Various RAL Colors |

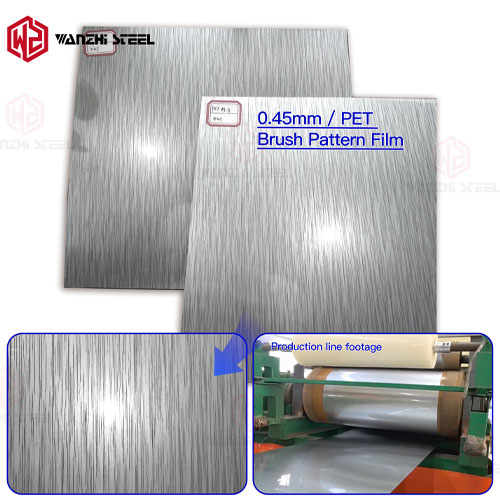

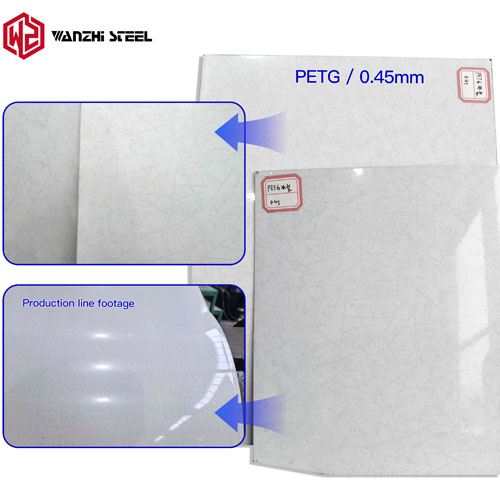

| Film Patterns | Wood Grain, Brushed Grain, Marble Grain, Matte, Glossy, Various Metallic Colors |

| Film Type | PET Film / PVC Film |

| PET Film Thickness | 25μm – 100μm |

| PVC Film Thickness | 80μm – 300μm |

| MOQ | 5 tons |

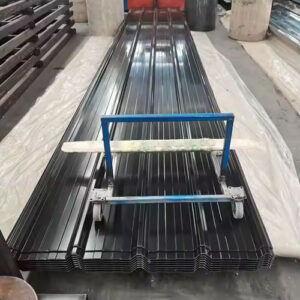

| Packaging | Vertical/horizontal packaging for steel coils, conventional export packaging for steel sheets |

Production Process Overview

Laminated film metal coil is a high-tech product manufactured through a high-temperature, high-pressure process. This process precisely and permanently bonds PET (polyethylene terephthalate) or PVC (polyvinyl chloride) film, pre-coated with a high-performance adhesive, to the surface of a metal substrate.

Production Video

Advantages of Laminated PET/PVC Film Metal Coil

The core strengths of laminated PET/PVC film metal coil lie in its integration of exceptional physical properties, decorative aesthetics, environmental safety, and cost-effectiveness.

Exceptional Physical Properties

- High Strength & Impact Resistance: Utilizing a metal substrate as core support, it delivers high strength and excellent impact resistance.

- Superior Weather Resistance: The surface film forms a robust barrier, offering excellent moisture resistance, corrosion resistance, and chemical resistance.

- Exceptional Dimensional Stability: Minimal impact from temperature and humidity fluctuations ensures precision during processing and installation.

Decorative and Functional Excellence

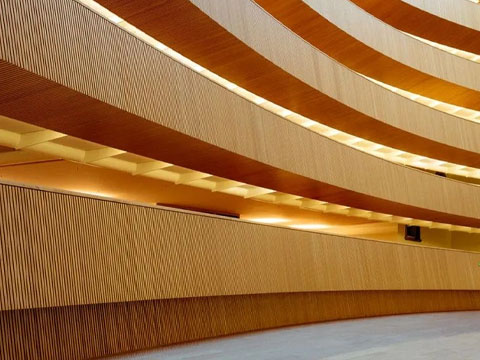

- High-Aesthetic Appeal: Smooth, flat surface available in diverse colors, realistic wood/stone patterns, and finishes like glossy or matte.

- Easy-Clean Maintenance-Free: Superior stain resistance simplifies cleaning—daily grime wipes away effortlessly, significantly reducing upkeep costs.

Eco-Friendly and Safe

- Green and Healthy: Environmentally friendly and non-toxic material; production generates no harmful substances.

- Fire Safety Assurance: Meets flame-retardant standards, effectively slowing fire spread.

Cost-Effective and Efficient

- Exceptional Value: Initial procurement costs are lower than traditional metals like stainless steel, with extended lifespan and minimal maintenance requirements.

- Streamlined Processing for Cost Reduction: Superior workability supports diverse fabrication techniques including cutting, bending, and stamping.

Laminated PET/PVC Film Metal Coil Application Scenarios

- Construction & Decoration: Metal roofing, exterior curtain walls, ceiling panels, garage doors, insulated sandwich panels, interior partitions, etc.

- Home Appliances: Refrigerator, air conditioner, washing machine, microwave oven, water heater, and other appliance casings.

- Premium Furniture: Cabinet doors, wardrobe doors, coffee table tops, etc.

- Electronics: Mobile phones, tablets, laptops, and other electronic device casings.

- Automotive: Automotive interior components including dashboards, door trim panels, center console panels, etc.

Why Choose Us?

- We possess strong supply chain coordination capabilities, enabling rapid integration of multiple manufacturers required for laminated film metal coils to efficiently fulfill orders.

- We offer customization services covering substrate selection, film type, thickness, color, and texture.

- From raw materials to finished products, dedicated professionals conduct tracking and inspections to ensure product quality, with full support for third-party testing.

As a professional supplier of laminated film metal coils sheets with over 14 years of production and export experience, we hold multiple certifications including ISO 9001 and ISO 14001. As a trusted supplier, we have earned the confidence of global customers. Contact Wanzhi Steel today for a customized quote and technical consultation!