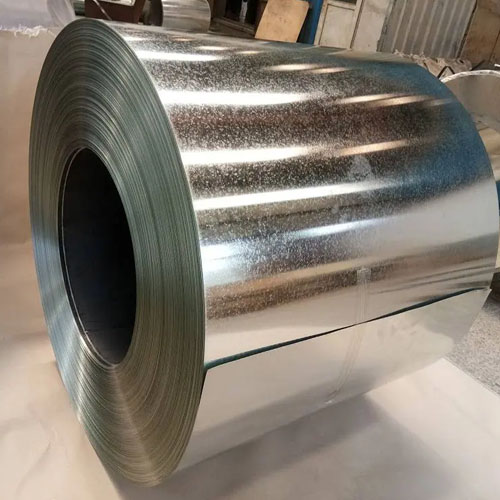

Hot Dipped Galvanized Steel

Hot-dip galvanized steel is corrosion-resistant and durable, and is widely used in construction, transportation, home appliances and other industries. As a professional manufacturer of galvanized products, Wanzhi Steel has two hot-dip galvanizing production lines and can provide hot-dip galvanized steel coils, hot-dip galvanized steel plates, hot-dip galvanized steel strips and other products.

Thickness: 0.12-4.0mm

Width: 600-1500mm

Place of Origin: Shandong, China

Transportation:By sea or Land transportation

tag: Galvanized steel

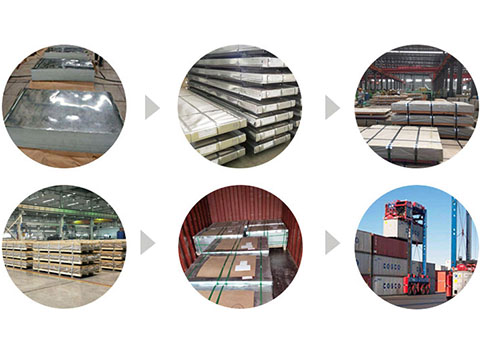

Ensure product quality and transportation

Hot-dip galvanized steel adopts hot-dip galvanizing production process, which can improve the corrosion resistance of galvanized steel. The common thickness of hot-dip galvanized steel plate is 0.3mm, 0.4mm, 0.5mm, 0.6mm, 0.8mm, 1mm, 1.2mm, etc., among which the most commonly used thickness is 0.4mm and 0.5mm.

Specifications of hot-dip galvanized steel

| Product Name | Hot dip galvanized steel |

| Substrate Material | Q195, Q235, DX51D, DX52D, DX53D, SPCC, SECC, A653, etc. |

| Standards | GB/ASTM/EN/JIS |

| Thickness | 0.15mm – 6mm |

| Zinc Coating Thickness | 30g/㎡ – 275g/㎡ |

| Width | 600mm – 1500mm |

| Length | 1,000mm – 6,000mm (sheets/plates) |

| Coil Weight | 3-8tons or customized |

| Surface Structure | Zero spangles, regular (normal) spangles, small (minimum) spangles, big spangles |

| Surface Treatment | Passivation treatment, oiling treatment, chromic passivation, etc. |

| Value-added services | slitting (gi strip), cutting (gi flat sheet), forming (gi corrugated sheet), etc. |

| Package | Standard export package |

Characteristics of hot-dip galvanized steel

- High corrosion resistance: The zinc coating exhibits excellent corrosion resistance, and hot-dip galvanizing offers a wide range of possible zinc coating thicknesses, reaching up to 275g/㎡, resulting in strong corrosion resistance.

- Strong and durable: Utilizing high-quality low-carbon steel raw materials ensures the strength, toughness, and ductility of GI coils and sheets, making them more durable.

- Excellent processing performance: The HDG substrate has good mechanical properties, allowing for processing operations such as slitting, bending, punching, forming, and welding.

Application of hot-dip galvanized steel

Hot-dip galvanized steel coils are often processed into products such as sheets, pipes, and profiles, and are used in the following fields and scenarios:

| Application Industries | Core Applications |

| Construction | Steel structure building roofs/walls, C/Z-shaped steel purlins, ventilation ducts, floor slabs. |

| Transportation Facilities | Highway guardrails, railway passenger cars, traffic sign poles. |

| Automobile Manufacturing | Body reinforcement plates, chassis supports, internal structural components, fuel tanks. |

| Daily Necessities & Industrial Products | Cable trays, filing cabinets, instrument housings, solar panel brackets. |

| Warehousing & Agriculture | Warehouse roofs/walls, grain silos, greenhouse frames, livestock and poultry farming equipment. |

Packaging

FAQ About HDG Steel

Q1: What is the difference between hot-dip galvanized steel and electrogalvanized steel?

A: The core difference between hot-dip galvanized steel and electrogalvanized steel lies in their distinct manufacturing processes and varying zinc coating weights. Hot-dip galvanizing (HDG) ranges from 30-275g/㎡, while EDG galvanizing ranges from 10-30 g/m². Electrogalvanized steel is also relatively more expensive. For corrosion protection purposes, we recommend selecting hot-dip galvanized steel.

Q2: What hot-dip galvanized steel products can we supply?

A: Utilizing slitting, cutting, punching, embossing, and forming equipment, we supply the following hot-dip galvanized steel products: hot-dip galvanized steel sheets (flat and corrugated), hot-dip galvanized steel pipes, hot-dip galvanized perforated sheets, hot-dip galvanized embossed steel, etc.

Q3: What are the minimum order quantity (MOQ) and delivery time?

A: Our standard specification MOQ is 10 tons. For certain special materials and compositions, the MOQ may be higher. Our delivery times are competitive within the industry, with fast production efficiency. Depending on the purchase quantity, delivery typically ranges from 5 to 30 days.

Our Production Line

Conclusion

The zinc layer of hot-dip galvanized steel (HDG) that Wanzhi Steel can provide ranges from 30-275g/㎡. Wanzhi has two hot-dip galvanizing production lines and one electrogalvanizing production line, with sufficient production capacity to accept bulk orders. Welcome to contact us to learn more about hot-dip galvanized steel products.

You may be interested: Galvanized steel sheet | Galvanized steel strip | Electro Galvanized Steel