HDP Color Coated Steel

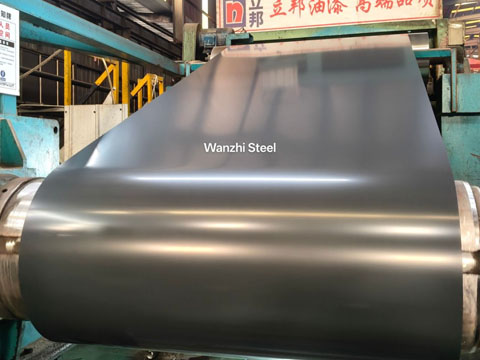

Wanzhi Steel’s HDP color-coated steel has strong weather resistance, rich colors, complete specifications, and long service life. If you have any needs, please feel free to contact us.

Production Thickness: 0.2mm-1.2mm

Width: 750mm-1250mm

Single-Sided Coating: 15-40µm

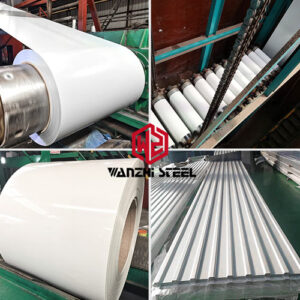

Ensure product quality and transportation

HDP color-coated steel, HDP (High Durability Polyester) is a polyester coating that is pre-coated on the surface of color-coated steel coils and has excellent weather resistance.

Specification

| Product Name | HDP Color Coated Steel |

| Production Thickness | 0.2mm – 1.2mm |

| Width | 750mm – 1250mm |

| Single-Sided Coating | 15-40µm |

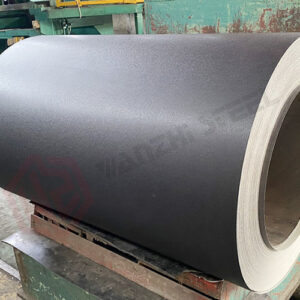

| Surface Finishes | Lamination, Mesh, Suede, Matte, Glossy, Fingerprint-Resistant, etc. |

| Substrate | Cold-Rolled Steel (CR), Hot-Dip Galvanized Steel (GI), Alu-Zn Coated Steel (GL/AZ), ZAM Steel |

| Coating | Z30 – Z275g/㎡, AZ30 – AZ150g/㎡ |

| Material | DX51D, DX52D, DX53D, SPCC, S250GD, S350GD, S550GD, A653, etc. |

| Inner Diameter (I.D.) | 508mm (20 inches) or 610mm (24 inches) |

| Coil Weight | 3 – 8 tons |

| MOQ | 5 tons |

| Packaging | Standard export package or as per your requirements |

Advantages of HDP Color-Coated Steel

- Strong Weather Resistance: Its UV resistance surpasses that of ordinary PE coatings, effectively controlling color shift and fading over time and making it suitable for most outdoor architectural applications.

- High Cost-Effectiveness: While priced lower than high-end PVDF paint coatings, it also offers excellent chemical and abrasion resistance, meeting the performance requirements of mid- to high-end architecture.

- Excellent Processability: The coating offers strong adhesion and flexibility, making it suitable for various shearing, bending, and deep-drawing processes, while remaining resistant to cracking.

- Wide Application Range: The mature process allows for easy processing, making it suitable for a wide range of applications requiring high weather resistance, such as industrial plants and commercial buildings.

Applications of HDP Color-Coated Steel

| Processed Products | Main Application Areas | Application Examples |

| Color Coated Profile Sheet | Industrial/Logistics Buildings | Roofs and exterior walls of factories, warehouses, workshops, and temporary buildings |

| Metal sandwich panels | Commercial/Residential Buildings | Cold storage, shopping mall partitions, office buildings, gymnasiums, and airport auxiliary buildings |

| Printed steel coils (wood grain, stone grain) | Construction/Home Appliances/Automotive | Exterior wall decoration, roofs, partitions, ceilings, cabinet panels, appliance housings, and automotive interior and exterior trim |

| Color-coated flat sheets | Furniture/Home Appliances | File cabinets, lockers, office partitions, kitchen cabinets, refrigerator/washing machine/air conditioner housings |

| Building accessories | Architectural Decoration | Awnings, downspouts, ventilation ducts, and interior ceilings |

HDP VS PVDF

Both HDP and PVDF are weather-resistant, but PVDF is more weather-resistant. Of course, PVDF is also the most expensive. HDP is the most cost-effective material, meeting most building requirements. PVDF is considered high-end and is used for projects that require extreme durability and quality.

| Items | HDP | PVDF |

| Chemical Composition | Modified polyester resin, more stable molecular structure | Polyvinylidene fluoride resin, extremely chemically inert |

| Weather Resistance | Excellent | Excellent (gold standard) |

| Color Retention | Good (10-15 years) | Excellent (over 20 years) |

| Chemical Resistance | Good, resistant to general contamination and cleaning agents | Extremely strong, resistant to strong solvents and severe chemical contamination |

| Flexibility & Processability | Excellent, strong adhesion, easy deep drawing and bending | Good, but aggressive processing may damage the coating |

| Cost | Medium | High |

| Main Applications | Standard industrial plants, logistics warehouses, commercial buildings, home appliances | High-end landmark buildings, airports, stadiums, hospitals, high-end office buildings, coastal structures |

Why Choose Us?

- We have three color-coated steel production lines, equipped with advanced equipment and a comprehensive range of specifications. Our products offer minimal color variation (compared to the Ral color chart) and a long service life.

- We utilize our own testing center to thoroughly inspect our products for specifications, physical properties, corrosion resistance, and weather resistance to ensure quality.

- We offer processing services such as punching, cutting, slitting, and profiling, offering a wide variety of products.

- We are ISO 9001, ISO 14001, ISO 45001, and certified as a trusted supplier.