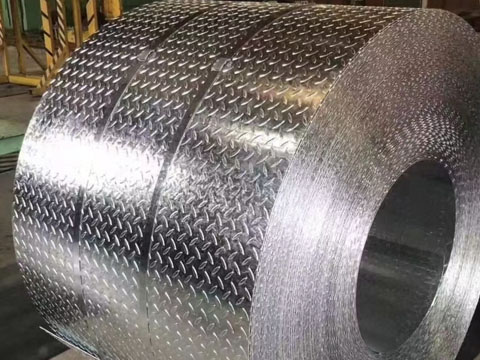

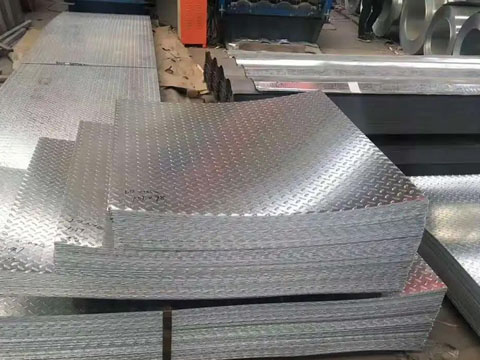

Galvanized Checker Plate

Wanzhi galvanized checker plate has rich surface pattern types, complete specifications, neat cuts, and supports customized processing.

Width: 600 -1500mm

Thickness: 1.5 – 6mm (excluding pattern thickness)

Length: 2000 – 12000mm, Cutting according to customer requirements

Material: Q235,Q355B, DC51D, SS400, S275JR ,etc

Ensure product quality and transportation

Galvanized checker plate is a galvanized steel plate with raised patterns on the surface. It is a variety of three-dimensional patterns formed by pressing with a pattern roller. It can improve the friction performance of the steel plate surface. It has both the corrosion resistance of galvanized steel and anti-skid performance.

Specifications of Galvanized Checker Plate

| Product Name | Galvanized Checker Plate |

| Width | 600 -1500mm |

| Thickness | 1.5 – 6mm (excluding pattern thickness) |

| Length | 2000 – 12000mm, Cutting according to customer requirements |

| Material | Q235,Q355B, DC51D, SS400, S275JR ,etc |

| Standard | GB, ASTM,JIS, EN, etc. |

| Production Process | Hot dip galvanizing, electro galvanizing |

| Zinc Coating | 30-275g/m² |

| Surface Types | Diamond, rhombus, lentil, round bean, square, etc. |

| Processing Services | Cutting, bending, welding, etc. |

| MOQ | 10 tons |

| Packaging | Standard export package or as per your requirements |

Characteristics of Galvanized Checker Plate

- Good corrosion resistance: The zinc layer on the surface of the steel plate can effectively isolate air and moisture, protecting the steel plate from oxidation and corrosion.

- Excellent anti-slip performance: The patterns of different shapes on the surface greatly enhance the friction of the surface and have excellent anti-slip performance.

- Strong decorative effect: The surface of the galvanized checker plate has a silvery-white luster, and different patterns (such as diamond patterns, rhombuses, and squares) can enhance the visual effect.

- High strength and durability: The substrate strength and toughness of the galvanized checker plate are very good, and the corrosion resistance of the surface zinc layer makes the steel plate very durable.

- Good processing performance: It is easy to perform processing operations such as cutting, bending, and welding to meet the production needs of different projects.

Application of Galvanized Checker Plate

- Architecture: industrial platform, stair treads, anti-skid floor, walkway platform.

- Transportation: vehicle chassis, carriage board, container floor, anti-skid tread, ship deck, etc.

- Industry: mechanical equipment treads, shelf layers, conveyor belts, anti-skid workbenches.

- Municipal engineering: bridge sidewalks, underground passage anti-skid plates, park trails, stadium stands, anti-skid ramps, etc.

- Others: agricultural machinery, freezer floors, decorative curtain walls.

Benefits of Using Galvanized Checker Plate

- The raised pattern on the surface can greatly improve safety performance.

- Strong corrosion resistance, long service life, and reduced replacement frequency.

- Galvanized checker plate is much cheaper than stainless steel checker plate.

Why Choose Us?

- We are ISO 9001:2015 certified and are an honest, contract-abiding and quality-oriented enterprise certified by an authoritative organization.

- We have more than 14 years of export experience, rich experience in the steel industry and export experience, and can solve all your problems.

- We have complete testing equipment and strict testing procedures to ensure product quality and meet customer requirements.

Wanzhi Steel is an enterprise with 17 years of experience in steel industry production. Its popular products are coated steel and color-coated steel, and include products with different surface types, such as galvanized checker plate. If you have demand for this type of steel, please contact us.