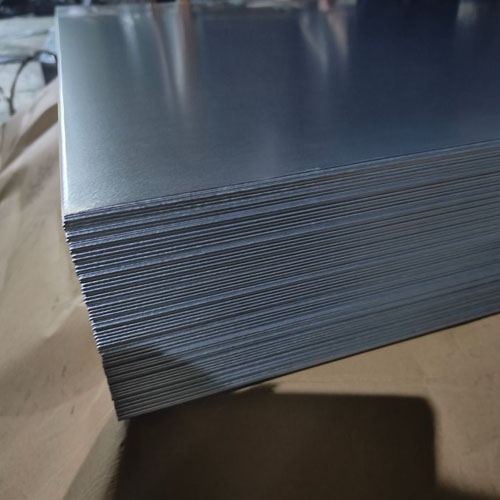

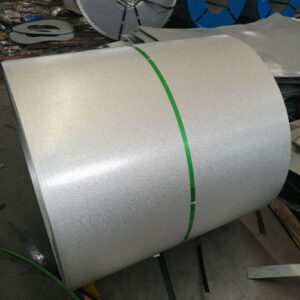

G90 Galvanized Steel

Wanzhi Steel produces G90 galvanized steel of various specifications and standards, and can be processed into coils, strips, sheets and pipes, etc. Under the premise of ensuring quality, we provide you with the most competitive prices.

Thickness: 0.12 – 4.0mm

Width: 300 – 2000mm or as your request

Material: DX51D, DX52D, DX53D, Q235, Q345, SPCC, SGCC, A653, A653M, etc.

tag: Galvanized steel

Ensure product quality and transportation

G90 galvanized steel represents 0.9 ounces of zinc per square foot. This coating has strong corrosion resistance, can maintain stable performance in harsh environments, and has a long service life.

We have 1 hot-dip galvanizing production line (Z30-Z275g/㎡) and 1 electro-galvanizing (not exceeding Z30g/㎡) production line.The annual production capacity of galvanized steel is more than 50,000 tons, which can meet various application requirements and have the production capacity of large-volume orders.

G90 Galvanized Steel Specifications

| Product Name | G90 Galvanized Steel |

| Thickness(mm) | 0.12 – 6.0mm |

| Width(mm) | 300 – 2000mm or as your request |

| Length(mm) | According to your requirements |

| Material | DX51D, DX52D, DX53D, Q235, Q345, SPCC, SGCC, A653, A653M, etc. |

| Standard | GB, JIS, EN, ASTM etc. |

| Coating Thickness | G90 (275g/㎡) |

| Spangle Type | Zero spangle, small spangle, regular spangle, large spangle |

| Surface Treatment | Passivation, oiling, fingerprint resistance, pre-painting, etc. |

| Processing Services | Profile processing, slitting, cutting, punching, welding, etc. |

| MOQ | 25 Tons |

| Packaging | Standard export package or as per your requirements |

| Delivery Time | 15-25 working days after payment |

Production Video

G90 Galvanized Steel Advantages

- Superior Corrosion Resistance: G90 denotes a zinc coating weight of 275g per square meter, representing an exceptionally thick galvanized layer that far exceeds conventional galvanized steel. It delivers ultimate corrosion resistance.

- Robust Durability: The high strength of the base material, combined with the zinc coating, ensures both corrosion resistance and structural integrity; it is highly durable.

- Efficient Processing: G90 galvanized steel offers excellent formability, enabling cutting, bending, welding, punching, and other fabrication processes.

- Surface Appearance: The zinc coating imparts a clean, bright silver-white finish with a classic zinc grain pattern, making it suitable for direct use as exposed decorative elements.

Additionally, zinc-free surfaces can be pre-painted to achieve various colors (pre-painted galvanized steel coils), meeting diverse decorative requirements.

Application of G90 galvanized steel

1. Construction Sector

- Roofing and Wall Panels: Widely used in industrial plants and warehouses for roof and wall cladding.

- Building Components: Manufactured into beams, columns, purlins, light steel studs, ventilation ducts, and other structural elements.

- Transportation Infrastructure: Used in municipal guardrails, highway barriers, bridge crash barriers, and road sign backing panels.

2. Home Appliances and General Manufacturing

- Home Appliances: Refrigerator side panels, washing machine and air conditioner back panels, internal brackets, and housings.

- Enclosures and Office Furniture: Used in manufacturing network cabinets, transformer housings, distribution panels, electrical control boxes, and filing cabinets.

3. Agricultural and Storage Facilities

- Agricultural Machinery: Used in manufacturing grain conveying equipment, tractor chassis components, harvester grain tank shells, irrigation pipe supports, etc.

- Storage and Transportation Equipment: Shelving, storage cages, grain silos, feed mixing tanks, etc.

G90 VS Z275

G90 Meaning

- G90 represents the coating code in the imperial unit (oz/ft²) under the ASTM 653/653M standard.

- “G” stands for galvanized.”90″ stands for the average minimum weight of the galvanized amount measured at three points on both sides, which is 0.9 ounces.

- The larger the number, the more galvanized the amount and the thicker the zinc layer.Common coating codes: G30, G60, G90, G185, etc.

Z275 Meaning

- Z275 represents the coating code in the metric unit (g/m²) under the EN 10327 standard.

- “Z” stands for galvanized.”275″ stands for galvanized amount of 275g/㎡.

- Similarly, the larger the number, the thicker the zinc layer.Common coating codes: Z30, Z60, Z120, Z275, etc.

Comparison of galvanized amount

After understanding the meaning of G90 and Z275, which one has a higher galvanized amount? Calculated in metric units, the weight of G90 coating is equivalent to about 275g/m² of zinc coating, and the galvanizing amount of the two is basically the same. The calculation method is as follows:

1oz=0.0284kg, 0.9oz=0.02556kg=25.56g, 1ft²=0.093m².

The above results in 0.9oz/ft²=25.56g/0.093m², that is, the galvanizing amount of 0.093 square meter is 25.56g, so the galvanizing amount of 1 square meter is 274.83871g.It verifies that the galvanizing amount of G90 and Z275 is basically the same.

Different standard galvanizing codes represent

| Standard No. | Standard Name | Unit | Typical codes for equal thickness coating |

| ASTM 653/653M-13 | Technical requirements for hot-dip galvanized and zinc-iron alloy steel strips | Imperial Units oz/ft² | G30、G40、G60、G90、 G100、 ….…G300、 G360 |

| Metric SI units g/m² | Z90、Z120、Z180、 Z275、 Z500、 Z900、Z1100 | ||

| EN 10327-2004 | Continuously hot-dip galvanized and electro-galvanized steel sheets and strips | Metric SI units g/m² | Z100、Z140、Z200、 Z225 Z275、 …Z450、 Z600 |

| JIS G3302-2010 | Hot-dip galvanized steel sheets and strips | Metric SI units g/m² | Z06、Z08、Z10、Z12、 Z27、. ….Z45、Z60 |

| GB/T 2518-2008 | Continuously hot-dip galvanized steel sheets and strips | Metric SI units g/m² | 60、80、100、120… 450、 600 |

Why choose us

- We are a professional galvanized steel coil manufacturer in China, holding international certifications including ISO 9001 and CE. With over 14 years of production experience, we have successfully exported to more than 120 countries.

- We maintain a comprehensive inspection system covering the entire process from raw materials to finished products, rigorously testing every batch for coating weight, dimensional tolerances, mechanical properties, and corrosion resistance.

- We offer specialized value-added services including precision cutting to length, slitting, punching, and forming. Whether you require galvanized coils, sheets, strips, or corrugated sheets, we can supply it.

When sourcing G90 galvanized steel, choosing the right partner is crucial. With 14 years of expertise in galvanized steel, Wanzhi Steel delivers end-to-end solutions—from quality control to service implementation. Share your specific requirements: thickness, width, coating specifications (e.g., G90), and intended application. Our seasoned team will promptly provide competitive pricing and expert technical support.