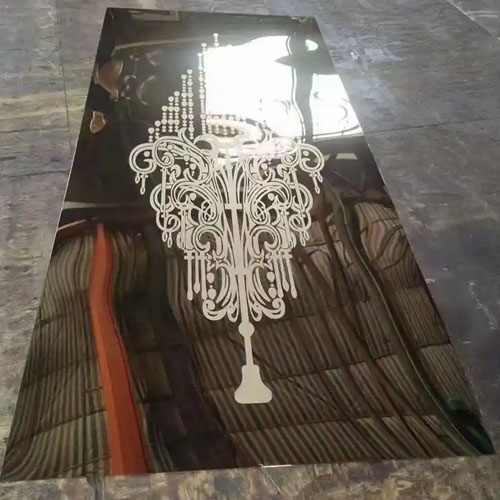

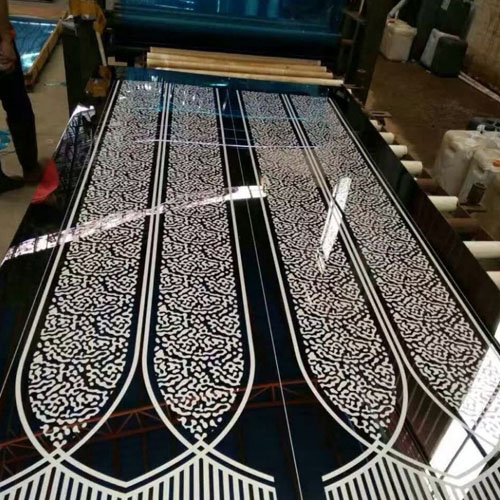

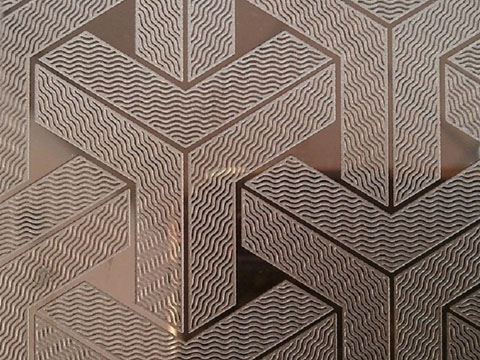

Etched Stainless Steel

The etched stainless steel we supply has rich patterns, high etching accuracy and a wide range of sizes. If your project requires decorative stainless steel, please feel free to contact us.

Thickness: ≥0.3mm

Size: 1000mm × 2000mm;1220mm × 2440mm;1500mm × 3000mm or customized

Etching lines: ≥0.2mm

Etching depth: 0.5 – 1.0mm

Ensure product quality and transportation

What is Etched Finish Stainless Steel

Etched finish stainless steel is a stainless steel material that uses an etching process to process patterns, textures or text on the stainless steel surface.It is a stainless steel material that combines functionality and aesthetics, retaining the excellent properties of stainless steel such as corrosion resistance and wear resistance, and giving it a unique aesthetic effect through surface treatment.

Specifications Available From Wanzhi

| Product name | Etched Stainless Steel |

| Thickness | ≥0.3mm |

| Size | 1000mm × 2000mm;1220mm × 2440mm;1500mm × 3000mm or customized |

| Etching lines | ≥0.2mm |

| Etching depth | 0.5 – 1.0mm |

| Material | 304, 316, 321, 430, 409, 410, 420, 201, 301, 2205, etc |

| Colors | Black titanium, violet, rose red, rose gold, coffee gold, red bronze, green bronze, brown, champagne gold, wine red, dark brown gold, bronze, gray titanium, etc. |

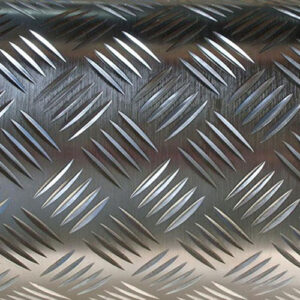

| Surface treatment | Polishing, brushing, electroplating, spraying, etc. |

| Technology | Hot Rolled / Cold Rolled |

| MOQ | 5 tons |

| Packing | Standard export package or as per your requirements |

Characteristics of Etched Stainless Steel

- High aesthetics: Through the etching process, various patterns, patterns, texts, etc. are etched on the surface of stainless steel, which has a beautiful appearance and strong decorativeness.

- Strong corrosion resistance: Stainless steel itself has good corrosion resistance, and it can still maintain this property after etching, which is suitable for corrosive environments such as moisture, acid and alkali.

- Good strength and toughness: Etching will not significantly reduce the strength and toughness of stainless steel, and it can still withstand certain pressure, tension and impact.

- Strong flexibility: Etched stainless steel can form patterns and texts of any shape on its surface to meet the customization needs of various shapes and sizes.

- High precision: The etching process can process small and complex patterns and texts, which is very suitable for the production needs of high-precision parts.

Application of etched stainless steel

Etched finish stainless steel and brushed, mirror stainless steel, etc. are all decorative stainless steel. Etched stainless steel is often used in the following scenes:

- Walls, columns, doors and windows of high-end buildings.

- Indoor and outdoor decoration, elevators, bathrooms, etc. of hotels.

- Corporate logos, signboards, commemorative plaques, etc.

- Refrigerator panels, artistic chandeliers or dining table decorations, etc.

- Metal box shells, mechanical equipment shells, etc.

- Automobile interiors, ship interiors, train interiors, etc.

- Sculptures, murals, decorative paintings, etc.

What Materials of Stainless Steel Can Be Etched

- 304 stainless steel: The most commonly used etched stainless steel material, suitable for most etching applications.

- 316 stainless steel: In etching processing, 316 stainless steel can withstand more complex etching processes.

- 321 stainless steel: During etching, 321 stainless steel can maintain stable performance.

- 430 stainless steel: In etching processing, the etching speed is easy to control.

- 409 stainless steel: 409 stainless steel etching products are often used in automotive exhaust systems, industrial pipelines and other fields.

- 410 stainless steel: 410 stainless steel is often used in knives, mechanical parts and other occasions that require higher strength after etching.

- 420 stainless steel: Suitable for making high-precision etching parts, such as surgical instruments or molds.

- 2205 duplex stainless steel: In the etching process, 2205 duplex stainless steel can withstand greater etching stress, and the etched products have higher dimensional accuracy and surface quality.

Why Choose Us?

Wanzhi Steel has more than 300 etching molds, using imported etching liquid, high etching accuracy and high surface uniformity. In addition to etching finishes, it can also supply brushed, mirror, matte, 2B, BA and other surface types of stainless steel, with a variety of specifications. If you have any needs for stainless steel products, please feel free to contact us.