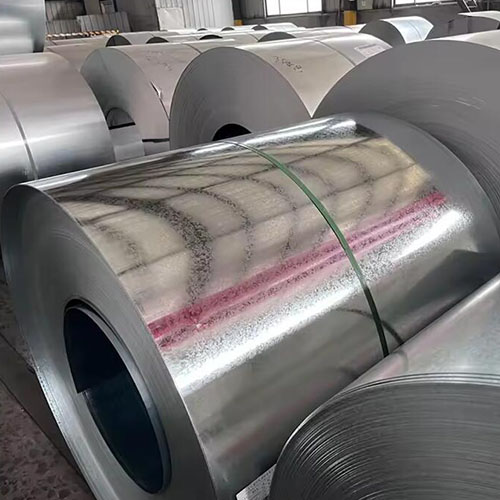

Electro Galvanized Steel

Electrogalvanized steel (EGI), also known as cold-dip galvanized steel, is a steel material coated with a layer of zinc through electrolysis. It has a certain degree of corrosion resistance and is cheaper than hot-dip galvanized steel. Electrogalvanized steel has become a popular choice for indoor steel applications.

Thicknesses:0.3mm-2mm

Width:600mm-1,500mm

Trade Term:FOB,CFR,CIF

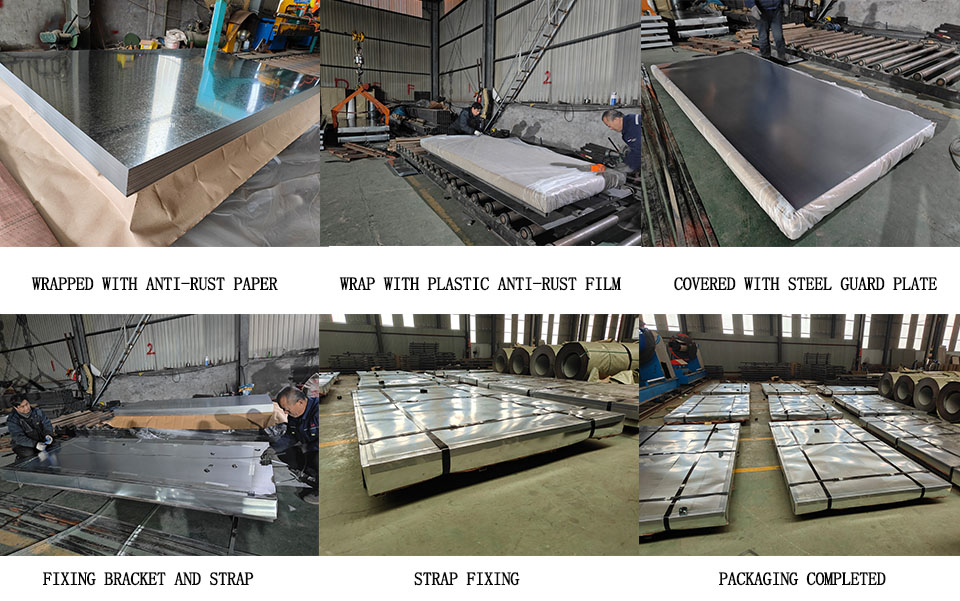

Packaging :Export standard, Seaworthy package or as required

Loading Port:Tianjing Qingdao Shanghai or as required

tag: Galvanized steel

Ensure product quality and transportation

Electrolytic galvanizing is the process of forming a uniform and dense zinc layer on the surface of steel through the electroplating process.

The electro-galvanizing process is an electrochemical process, which is to put the cold-rolled steel into a charged and salt water solution to chemically combine the zinc and steel.

Electro galvanized steel types are commonly found in steel coils, steel plates, corrugated steel plates, and can also be welded into steel pipes. If you need electro galvanized steel, please contact Wanzhi.

Specifications of electro galvanized steel

| Product Name | Electro Galvanized Steel |

| Base Metal | Cold rolled steel |

| Thicknesses | 0.12mm-2mm |

| Width | 600mm-1,500mm |

| coating | 10-30g/㎡ |

| Type | Coil/sheet/strip or as required |

| Usage | Electronic parts, furniture, automobile panels, internal parts, door frames, etc. |

| Surface Treatment | Chromated and Oiled, Chromated and Non-Oiled |

| Quotation method | EXW, FOB, CIF, CFR etc. |

| Packaging | Export standard, Seaworthy package or as required |

| Loading Port | Tianjing, Qingdao, Shanghai or as required |

| Delivery Time | 15-25 working days after payment or as customer required |

| other service | Customized logo,Customized packaging. |

Electro galvanized steel production video

Grades of electro galvanized steel

| Type | Symbol | Coating Mass(g/m2) | Thickness(mm) | Width(mm) |

| For Common | SECC | 10-40 | 0.4-2.0 | 800-1400 |

| For Drawing | SECD | 10-40 | 0.4-2.0 | 800-1400 |

| For Deep | SECE | 10-40 | 0.4-2.0 | 800-1400 |

Characteristics of electro galvanized steel

- The zinc layer is fine and uniform, not easy to be corroded, and has good corrosion resistance.

- Because the zinc layer has ductility, it can withstand various bending, cold punching, bending, and has good processing performance.

- The appearance of electro galvanized steel is bright, beautiful and generous, and has a certain decorative effect.

- Electro galvanized steel has excellent wear resistance.

Application of electro galvanized steel

Electro galvanized steel is widely used, and is commonly found in home appliances, steel furniture, office equipment, automobiles, construction, machinery manufacturing and other fields.

- Roofing and wall materials

- Door and window frames

- Building interior frames and brackets

- Automobile bodies and parts

- Manufacturing of various hardware accessories

- Computer mainframes, monitor housings, electronic equipment cabinets, etc.

FAQ electro galvanized steel

Which is better, electro galvanized or hot-dip galvanized steel?

Both electrogalvanizing and hot-dip galvanizing have advantages and disadvantages. Hot-dip galvanizing has strong corrosion resistance and high strength, but the cost is higher. Electrogalvanizing has poorer anti-corrosion performance than hot-dip galvanizing, but the production process is simple and the cost is low.

It is worth mentioning that the two are used in different places. Hot-dip galvanizing is mostly used in outdoor steel such as highway fences, while electro-galvanizing is mostly used in indoor steel such as panels.

Will electro-galvanized steel rust?

Electro-galvanized steel has certain anti-corrosion properties, but it will rust after a long time of use. However, even in a highly corrosive environment, the life of electro-galvanized steel produced by Wanzhi can reach more than 10 years. If you need steel with strong anti-corrosion properties and long life, hot-dip galvanized steel is recommended.

packaging

Why Choose Us

- With more than 13 years of export experience, the company has passed ISO 9001:2015 certification and is trustworthy.

- We have an electrogalvanized steel production line with an annual output of more than 100,000 tons, sufficient production capacity and fast delivery.

- The products are tested for performance, specifications, appearance, etc. to ensure product quality, and support third-party testing.

- With equipment such as fixed-length cutting, longitudinal shearing, pressing and stamping, we can provide various types of electrogalvanized steel.

- The perfect customer service team perfectly solves all pre-sales and after-sales problems for you.

As a professional electro-galvanized steel supplier in China, Wanzhi Steel are committed to providing you with competitive prices and high-quality products.If you need to purchase electrogalvanized steel or other coated steel products, please feel free to contact us for details.

You may be interested: Galvanized Steel Coils | Hot dip galvanized steel | Galvanized steel strip