Dx51d Z275

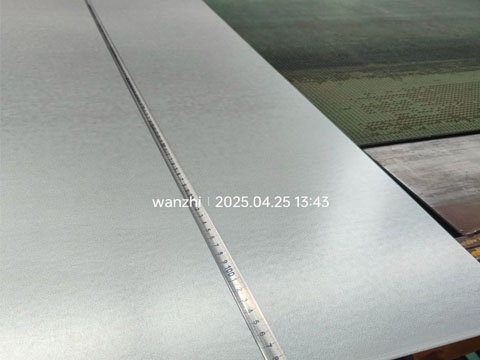

DX51D Z275 is galvanized steel with excellent corrosion resistance. We have two hot-dip galvanized steel production lines to produce DX51D Z275 in a full range of sizes and thicknesses.

Thickness: 0.3 – 0.5mm

Width: 600 – 1500mm or customized

Length: Cut as needed (C)

Spangle type: Zero spangle, small spangle, regular spangle, large spangle

Ensure product quality and transportation

DX51D Z275 is a hot-dip galvanized steel conforming to the European standard (EN 10346) and is a more widely used GI steel.

The meaning of DX51D: the first D stands for cold forming steel; X stands for unspecified rolled condition of the base material, 51 indicates the grade number; the last D indicates hot-dip galvanized.

Dx51d Z275 Technical Information

Dx51d Z275 Specification

| Product name | Dx51d Z275 Galvanized Steel |

| Thickness | 0.3 – 5mm |

| Width | 600 – 1500mm or customized |

| Length | Cut as needed (C) |

| Zinc Coating | Z275 |

| Material | Dx51d |

| Standard | EN 10346 |

| Spangle type | Zero spangle, small spangle, regular spangle, large spangle |

| Processing service | Shearing, stamping, bending, welding, pressing, etc. |

| Surface treatment | Chemical passivation, oiling, chemical passivation and oiling, pre-painting, etc. |

| Coil inner diameter | 508mm or 610mm |

| Coil weight | 3 – 5 tons or customized |

| MOQ | 10 tons |

| Packaging | Standard export package or as per your requirements |

Dx51d Z275 Chemical Composition

| Element | C | Mn | P | S | Si | Al |

| Content | ≤0.18% | ≤1.50% | ≤0.12% | ≤0.045% | ≤0.03% | ≤0.020% |

Dx51d Z275 Mechanical Properties

| Mechanical properties | Yield strength | Tensile strength | Elongation after break |

| Typical values | 160 – 220 MPa | 270 – 500MPa | 25% – 35% |

Grade Comparison

| Grade | Tensile strength (range) | Yield strength (range) | Elongation after break |

| DX51D+Z275 | 270 – 500 MPa | ≥140 MPa | ≥22% |

| DX52D+Z275 | 270 – 420 MPa | ≥180 MPa | ≥26% |

| DX53D+Z275 | 270 – 380 MPa | ≥220 MPa | ≥30% |

Dx51d Z275 Equivalent Grade

| Country | China (GB/T 2518) | USA (ASTM A653) | Japan (JIS G 3302) | International (ISO 3575) |

| Equivalent grade | Q195/Q235+Z275 | CS Type B (G90) | SGCC Z27 | CR4 Z275 |

Dx51d Z275 Galvanized Steel Product Advantages

- Strong corrosion resistance: high galvanized layer, strong corrosion resistance, general environmental service life of 15 – 30 years.

- Excellent processing performance: suitable for shearing, stamping, bending, welding and other processing, processing is not easy to quality problems.

- Excellent surface quality: uniform plating, good surface finish, good appearance quality, can be used directly or as a color coated sheet substrate.

- High cost performance: while ensuring performance, the price is relatively reasonable, widely used in many industries, with high cost performance.

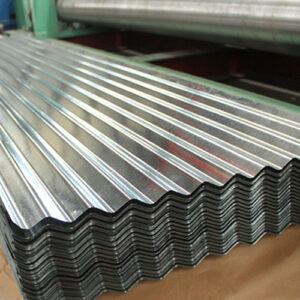

Dx51d Z275 Galvanized Steel Application

- Construction field: used for roof and wall covering, building enclosure, structural parts manufacturing, and ventilation duct processing.

- Automobile industry: for making carriage panels, body covering parts, chassis parts, etc.

- Home appliance industry: applicable to the manufacture of shells and internal components of all kinds of large and small home appliances.

- Hardware products: commonly used in the manufacture of furniture fittings and metal containers.

- Other aspects: also used in the construction of agricultural facilities (agricultural greenhouses, grain silos, etc.) and the manufacture of electrical cabinets, etc.

Why Choose Us?

- More than 17 years of production experience, more than 14 years of export experience, and passed ISO 9001, ISO14001 and other heat certificates.

- Using advanced production equipment and high-quality raw materials, not only high production capacity, but also excellent product quality.

- Equipped with a professional product testing center, the product will be tested for composition, performance, appearance, specifications, etc. to ensure product quality.

A professional metal coating manufacturer with a wide range of product types, our DX51D metal coating products include:

- DX51D+Z: hot-dip galvanized steel

- DX51D+AZ: hot-dip aluminum-zinc steel

- DX51D+ZA: hot-dip galvanized aluminum-steel

- DX51D+ZAM: hot-dip aluminum-zinc-magnesium

Wanzhi Steel has two hot-dip galvanized steel production lines and one electro-galvanized production line, with high production capacity, enough production capacity for large volume orders and fast delivery, if you have a need for galvanized steel products, please contact us for details.