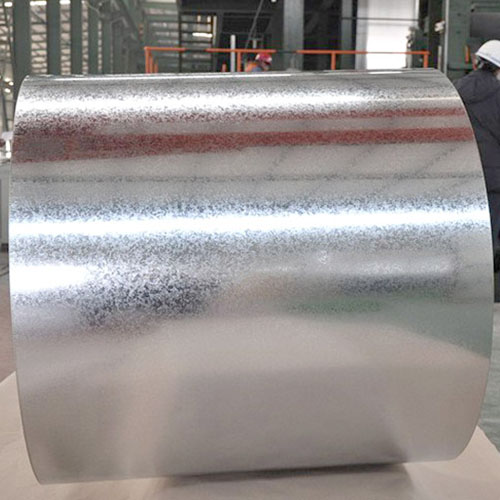

DX51D Coated Steel Coil

DX51D is a European standard and is often used as the substrate for coated steel coils, such as DX51D+Z, DX51D+AZ, DX51D+ZA, and DX51D+ZM. Wanzhi Steel specializes in supplying high-quality galvanized steel (GI), aluminum-zinc steel (GL), and zinc-aluminum-magnesium steel (ZAM) for DX51D substrates.

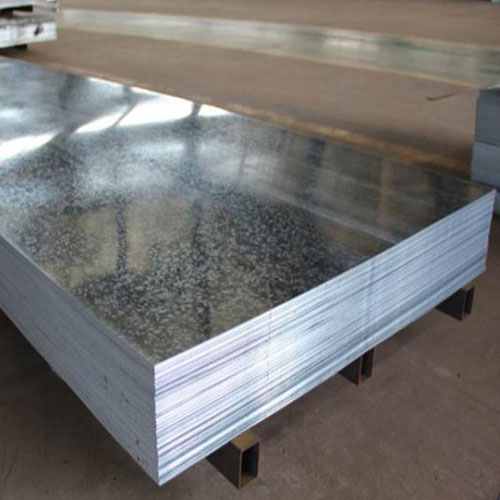

Thickness: 0.3 – 6.0mm

Width: 600-1500mm or as your request

Processing services: Slitting, Embossed, flattened, Pressed roof panels

Place of Origin: Shandong, China

tag: Galvanized steel

Ensure product quality and transportation

DX51D is a low-carbon steel produced in accordance with EN 10346 standards, making it an excellent substrate for a variety of advanced protective coatings. Wanzhi Steel specializes in providing DX51D coils with three superior coating solutions: galvanized (Z), galvalume (AZ), and zinc-aluminum-magnesium (ZM). The combination of a high-quality substrate and cutting-edge coatings results in finished products with exceptional corrosion resistance, high strength, and excellent heat resistance to meet your most challenging application needs.Our core products include:

- DX51D+Z: Standard galvanized (GI) steel coil, providing reliable and cost-effective protection.

- DX51D+AZ: Galvalume (GL) steel coil, offering superior atmospheric corrosion resistance, typically 2-4 times that of ordinary galvanized steel.

- DX51D+ZM: Zinc-aluminum-magnesium (ZAM) steel coil, offering the highest level of corrosion protection, particularly excellent cut-edge resistance, making it an ideal choice for harsh environments.

DX51D steel specification

| Product Name | DX51D Coated Steel Coil |

| Thickness | 0.3 – 6.0 mm |

| Width | 600-1500 mm or slitting upon request |

| Common Widths | 900 mm/1000 mm/1250 mm/1500 mm |

| Coating | Galvanized: Z30 – Z275 g/㎡ |

| Galvalume: AZ30-AZ150 g/㎡ | |

| Galvanized zinc aluminum magnesium: ZM60-ZM180g/㎡ | |

| Surface Treatment | Oil-coated, chrome-free passivated, oil-free, fingerprint-resistant, pre-painted, etc. |

| Processing Services | Slitting, embossing, flattening, and pressing roofing panels |

| MOQ | 10 tons |

| Payment Terms | EXW, FOB, CIF, CFR, etc. |

| Package | Standard export packaging |

| Shipping | Container, bulk carrier, train, or as per your requirements |

DX51D Chemical Composition

| Grade | C | Si | Mn | P | S | Ti |

| DX51D+Z,DX51D+ZF,DX51D+ZA,DX51D+AZ | ≤0.18% | ≤0.5% | ≤1.2% | ≤0.12% | ≤0.045% | ≤0.3% |

DX51D Coated Steel Properties

1. Corrosion resistance

DX51D has good corrosion resistance, and the zinc coating on the surface can prevent the DX51D substrate from reacting with oxygen and prevent rust.Even in harsh environments such as humidity and acid rain, the performance can remain stable.

2. Mechanical properties

DX51D mechanical properties are manifested in yield strength, tensile strength and elongation.

| Grade | Yield Strength MPa | Tensile strength(Rm/MPa) | Elongation after fracture |

| DX51D+Z,DX51D+ZF, DX51D+ZA,DX51D+AZ | – | 270-500 | ≥22% |

DX51D has a low yield strength, high strength and hardness, moderate tensile strength, good plasticity and toughness.

DX51D has a high elongation and is not easy to break after impact.

3. Good processing performance

DX51D has good plasticity and toughness, and can be processed by stamping, bending, folding, welding, etc. Good processing performance.

DX51D+Z VSDX51D+AZ VS DX51D+ZM

| Features | DX51D+Z (Galvanized GI) | DX51D+AZ (Aluzinc GL) | DX51D+ZM (Zinc Magnesium ZAM) |

| Coating Composition | 100% zinc | 55% aluminum, 43.4% zinc, 1.6% silicon | Zinc, aluminum, and magnesium alloys |

| Corrosion Resistance | Good | 2-6 times the strength of galvanized steel | 5-20 times better than galvanized steel (excellent edge protection) |

| Heat Resistance | General (approximately 230°C) | Good (up to 315°C) | Good |

| Main Applications | Interior decoration, roofs or walls in ordinary environments | Suitable for coastal buildings, automotive exhaust pipe components, and oven liners | Suitable for coastal facilities and marine engineering, high salt spray road guardrails, and outdoor furniture |

| Cost Effectiveness | Economical and cost-effective | Medium- to long-term investment with low maintenance costs | High initial cost, but lowest lifecycle cost |

FAQ about DX51D Coated Steel Coil

What does DX51D+Z275 mean?

DX51D+Z275 means DX51D galvanized steel with a zinc weight of 275g.Z is pure zinc coating, and 275 represents 275g zinc.

What material is DX51D equivalent to?

| EN 10346 | American Standard (ASTM) | Japanese Standard (JIS) | Chinese Standard (GB) | |

| DX51D+Z、DX51D+ZF、DX51D+ZA、DX51D+AZ | ASTM A792 Grade 33+* | JIS G 3321 SGLCC+* | GB/T 14978 DX51D+* |

What is the difference between DX51D and DC51D?

The standards of the two are different. DX51D uses the EU standard (EN10327), and DC51D is the Baosteel standard (Q/BQB402).

The carbon content of the two is different. The carbon content of DC51D is higher than that of DX51D.

Conclusion

Wanzhi Steel is able to produce different products with DX51D as the substrate, such as: DX51D+galvanized steel, DX51D+galvalume steel, DX51D+PPGI, DX51D+PPGL, etc. The products have high corrosion resistance and strong decorative properties. If there are any products that you are interested in, please feel free to contact us