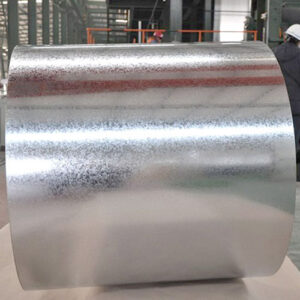

Aluzinc Roofing Sheet

We provide you with various specifications, colors, and types of Aluzinc Roofing Sheets, which can perfectly match the needs of your project. The precise size and optimal quality are highly recognized by customers.

Thickness: 0.12mm-2.0mm

Width: 600mm-1500mm

Coating Weight: AZ30-AZ185g/㎡

Ensure product quality and transportation

Aluzinc roofing sheet is a type of carbon steel sheet, which is composed of about 55% aluminum, about 43.% zinc and about 1.6% silicon. It has strong corrosion resistance and weather resistance, as well as high-quality appearance, and is widely used.

Generally speaking, the standards of the aluzinc roofing sheet substrates we produce include JIS (SGCC), ASTM (A653, A653M, etc.), EN (DX51D, DX52D, etc.), GB (Q235, Q345, etc.).

DX51D+AZ30g/㎡ means that the roofing substrate material belongs to the European standard EN10346, and the aluminum-zinc alloy layer plated on the surface of the roofing sheet is 30g per square meter.

When you leave a message to inquire about the product price information, in addition to the specifications and quantity information, you can specify the substrate material and the zinc layer weight, so that the price information obtained is more accurate.

Aluzinc Roofing Sheet Specifications

| Product Name | Aluzinc Roofing Sheet |

| Thickness(mm) | 0.12-2.0mm |

| Width(mm) | 600-1500mm |

| Length(mm) | According to customer requirements |

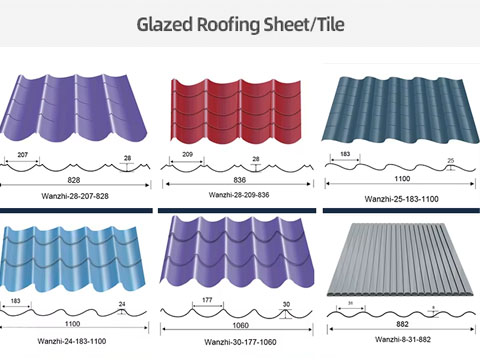

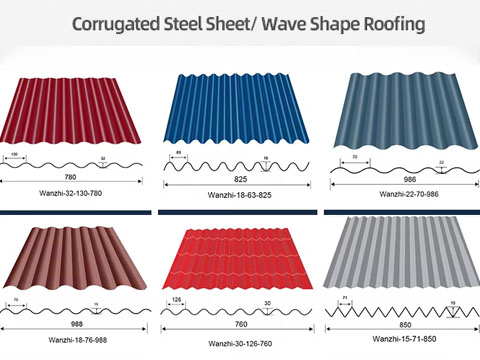

| Shape | Wave, trapezoid, tile shape, etc. |

| Coating Weight | AZ30-AZ150g/㎡ |

| Material | DX51D, DX52D, DX53D, Q235, Q345, SGCC, A653, A653M, etc. |

| Spangle | Zero spangle, Small spangle, Regular spangle, Large spangle |

| Standard | GB, ASTM, EN, JIS |

| Surface Treatment | Passivation, Fingerprint resistance, Oiling, Pre-painting, etc. |

| MOQ | 10 Tons |

| Packaging | Standard Export Package |

Advantages of Aluzinc Roofing Sheet

- Durable

- Lightweight and high strength

- Strong corrosion resistance

- Good weather resistance

- High heat reflectivity

- Easy maintenance

- High appearance quality

- Good fire resistance

Applications of Aluzinc Roofing Sheet

- Roof

- Building curtain wall

- Exterior wall cladding

- Indoor partition

- Background wall

- Highway guardrail

- Residential fence

- Shed

- Temporary building

What are the benefits of Aluzinc Roofing Sheet

Reduce costs

Due to the light weight of aluminum-zinc roofing sheets, they are easy to transport and construct, reducing transportation costs and installation time.

Improve building safety

Aluminum-zinc roofing sheets have high strength and strong weather resistance, and can withstand adverse weather conditions such as strong winds, heavy rains, hail, etc., ensuring building safety.

Improve the aesthetics of buildings

Aluminum-zinc roofing sheets have high appearance quality and a variety of colors, which can enhance the overall aesthetics of the building.

Energy saving and environmental protection

Aluminum-zinc roofing sheets can reflect solar heat, reduce air conditioning energy consumption, and achieve energy-saving effects. At the same time, aluminum-zinc roofing sheets can be recycled at the end of their life, which is beneficial to environmental protection.

Long service life

Aluminum-zinc roofing sheets have the advantages of super high temperature resistance, low temperature resistance, light resistance, corrosion resistance, aging resistance, etc., and have a long service life.

Precautions for using Aluzinc Roofing Sheet

- Aluzinc will react with metals such as copper or lead, which will accelerate the corrosion rate of Aluzinc Roofing Sheet. Avoid contact with these metals when using Aluzinc Roofing Sheet.

- Aluzinc Roofing Sheet will cause black rust or corrosion when in contact with certain woods (oak, chestnut, redwood, etc.).

- Aluzinc Roofing Sheet will cause discoloration or black rust when in contact with highly alkaline wet concrete, cement, asphalt, gypsum, etc.

Why buy our Aluzinc Roofing Sheet

Experienced Manufacturer

We are an ISO 9001:2015 certified factory with 13 years of experience in production and export, and our products are exported to more than 120 countries. Wanzhi factory provides you with wholesale prices, and if you purchase large quantities, the price discount is even greater.

Products are strictly tested

Our Aluzinc Roofing Sheet test items include thickness test, coating thickness test, tensile test, salt spray test (corrosion resistance), hardness test, UV resistance test (weather resistance), etc. If you need third-party testing, we also fully support it.

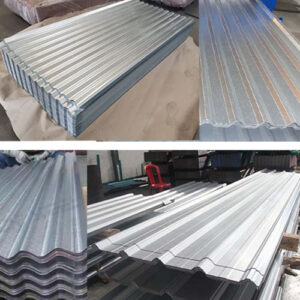

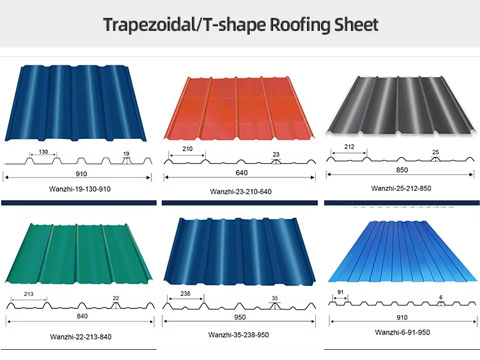

Complete range of roofing sheet specifications

We have a galvanized production line and hundreds of press-forming equipment, which can produce Aluzinc Sheets of different sizes and process various types of roofing sheets to meet your needs for different projects.You are welcome to contact us at any time to consult products