Aluminum Magnesium Manganese Roof Sheet

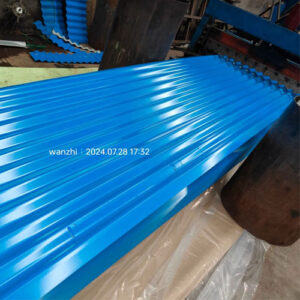

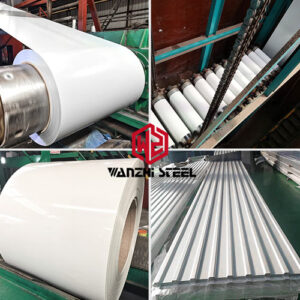

Aluminum-magnesium-manganese roof sheet with PVDF coating is a metal roof sheet with high corrosion and weather resistance. Wanzhi Steel offers high-performance PVDF-coated aluminum-magnesium-manganese sheet in a full range of specifications.

Thickness: 0.4-1.2mm

Width: <1500mm

Length: ≤12m

Material: AA3004, AA3005, AA3105

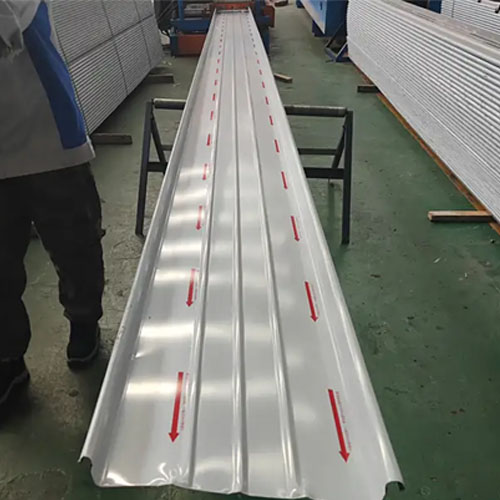

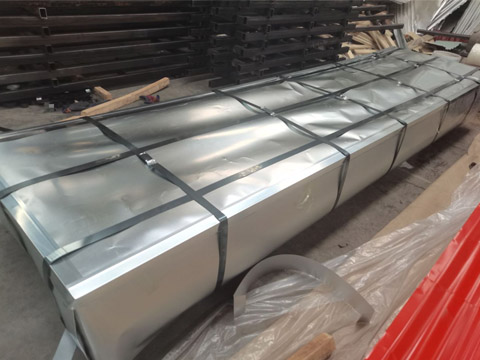

Ensure product quality and transportation

Aluminum-magnesium-manganese sheet is a new alloy material commonly used as a roofing material. It has a low density of approximately 2.73g/cm³, is lightweight, and offers excellent corrosion resistance.

Specification

| Product Name | Aluminum Magnesium Manganese Metal Roof Sheet |

| Thickness | 0.4-1.2mm |

| Width | <1500mm |

| Length | Cut to customer specifications |

| Material | AA3004, AA3005, AA3105 |

| Elongation | 12-21% |

| Applicable slopes | 5°-45° |

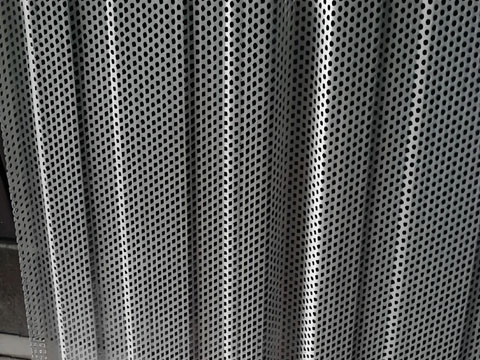

| Surface treatments | Hammered effect, color coating, etc. |

| Paint finish | PVDF |

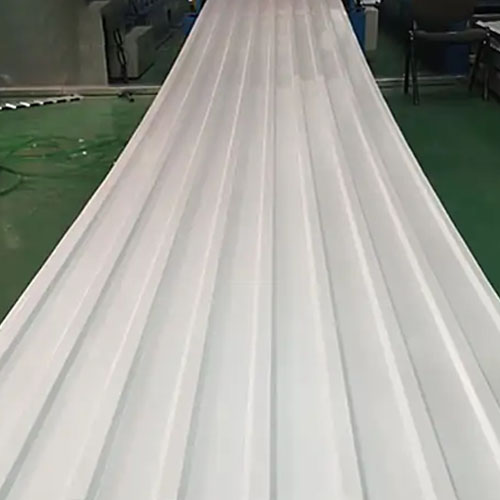

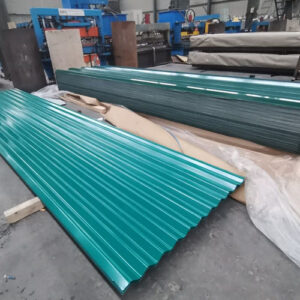

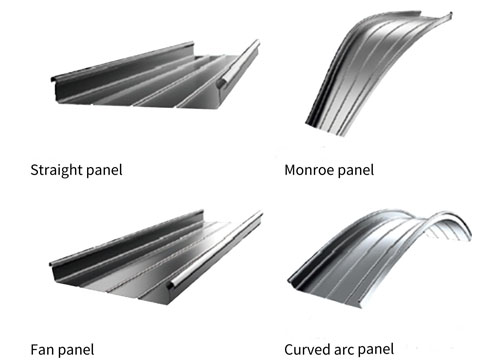

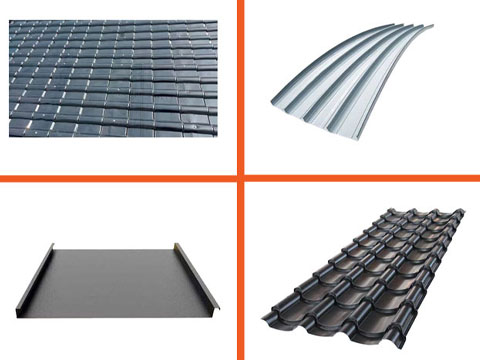

| Types | Standing seam, flat lock plate, antique metal tile, corrugated plate |

| MOQ | 5 tons |

| Packing | Standard export package or as per your requirements |

Chemical Composition

| Alloying Elements | Al | Mg | Mn | Fe | Si | Cu | Zn | Others |

| AA3004 | Remainder | 0.8 – 1.3% | 1.0 – 1.5% | ≤ 0.70% | ≤ 0.30% | ≤ 0.25% | ≤ 0.25% | ≤ 0.05% |

| AA3005 | Remainder | 0.2 – 0.6% | 1.0 – 1.5% | ≤ 0.70% | ≤ 0.30% | ≤ 0.30% | ≤ 0.25% | ≤ 0.05% |

Wanzhi Aluminum Magnesium Manganese Sheet Model

- Standing Seam: WZ-65-300, WZ-65-400, WZ-65-430, WZ-65-500

- Standing Edge Interlock: WZ-25-260, WZ-25-330, WZ-25-430, WZ-25-530, WZ-32-310, WZ-32-410, WZ-32-510, WZ-32-610, WZ-38-300, WZ-38-400, WZ-38-500, WZ-38-600

- Metal Antique Tiles: WZ55-255-765, WZ70-240-720

- Corrugated Sheets: WZ35-125-750, WZ32-130-780, WZ18-63.5-825

*Note: For example, WZ-65-300, WZ represents the Wanzhi brand, 65 represents the height, and 300 represents the width.

Aluminum Magnesium Manganese Roof Sheet Applications

PVDF-coated aluminum magnesium manganese roof sheet is primarily used for roofs and walls requiring high corrosion resistance or in high-end applications. Applications include the following:

| Application Areas | Typical Building Types |

| Large Public Buildings | Airport terminals, subway stations, high-speed rail stations, stadiums, convention centers |

| Municipal and Cultural Buildings | Libraries, museums, city cultural centers, science and technology museums |

| High-End Residential and Commercial Buildings | Villas, townhouses, high-end office buildings, commercial complexes (shopping malls) |

| Industrial and Transportation Facilities | Chemical plants, electronics factory workshops, highway service areas |

| Specialty Buildings | Cultural tourism town buildings, coastal area buildings, buildings in low-temperature regions |

Aluminum Magnesium Manganese Roof Sheet Advantages

- Extremely weather-resistant and extremely long service life: The base material is highly corrosion-resistant, and the PVDF coating provides exceptional weather resistance, achieving a service life of 25-30 years, even in environments with high salt spray and industrial pollution.

- Lightweight and high-strength: With a density of only approximately 2.7g/cm³, it significantly reduces the load-bearing capacity of building roofs. It also boasts a tensile strength of 200-300MPa, demonstrating high strength.

- Various types and adaptability: Its excellent ductility allows it to be processed into complex shapes such as arcs, scallops, and special shapes. It is suitable for curved roof designs on large-span buildings such as airports and stadiums.

Aluminum-magnesium-manganese roof Sheet VS PPGI corrugated Sheet

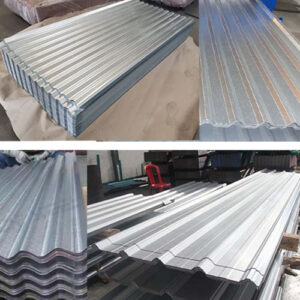

| Comparison Items | Aluminum-Magnesium-Manganese Roof Sheets | PPGI Corrugated Sheet |

| Core Materials | Aluminum-magnesium-manganese alloy (Al-Mg-Mn), based on aluminum, offers excellent corrosion resistance. | Galvanized steel (GI) is a steel base material, with the core protected by a galvanized surface layer for rust prevention. |

| Weight and Strength | Lightweight and High-Strength: Density approximately 2.73 g/cm³ (one-third that of steel), while lightweight yet possessing high strength through alloying. | Heavy weight – with a density of 7.85 g/cm³, it carries a high deadweight and requires high structural load-bearing capacity. |

| Weather and Corrosion Resistance | A self-formed, dense oxide film (Al₂O₃) provides excellent basic corrosion resistance; the PVDF coating offers salt spray and UV resistance. | Relying on the zinc layer for corrosion protection, it has poor salt spray resistance and is prone to zinc layer shedding and baseplate rust in coastal and high-humidity environments. |

| Processing and Styling | Excellent ductility allows for processing complex curved surfaces such as arcs, sectors, and special shapes, making it suitable for large-span buildings. | It can usually only be processed into regular wavy or trapezoidal arches, making it difficult to adapt to different designs. |

| Maintenance | The surface is hydrophobic and oleophobic, allowing dust and rainwater to slide off easily, resulting in low annual maintenance costs. | It is prone to dust accumulation and rust, requiring regular rust removal and repainting, resulting in relatively high annual maintenance costs. |

| Cost | Higher Costs | Relatively low |

| Application Scenarios | High-end public buildings (airports, stadiums), villas, coastal buildings, and cultural tourism projects | Suitable for general industrial plants, warehouses, temporary buildings, and low-end residential buildings with limited budgets. |

Packaging

Why Choose Wanzhi Steel?

- We have over a hundred press machines, capable of producing a full range of models and sizes.

- Advanced production equipment, professional technicians, and rigorous testing procedures ensure product quality.

- Direct from the factory, we offer wholesale pricing (minimum order quantity required), offering excellent value for money.

- We partner with multiple logistics companies to develop the most cost-effective logistics solutions for our customers, saving them money.

Wanzhi Steel is a professional metal roofing sheet manufacturer in China. Located in Shandong, our factory boasts over 14 years of production experience. We are ISO 9001, ISO 14001, and certified as a trusted supplier. If you have any metal roofing sheet procurement needs, please feel free to contact us.

You may be interested: PVDF Roofing Sheet | Galvanized Corrugated Roof Sheet | Galvalume Roofing Sheet