316 stainless steel

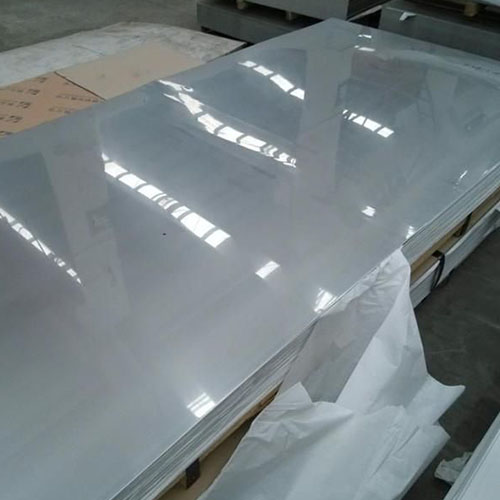

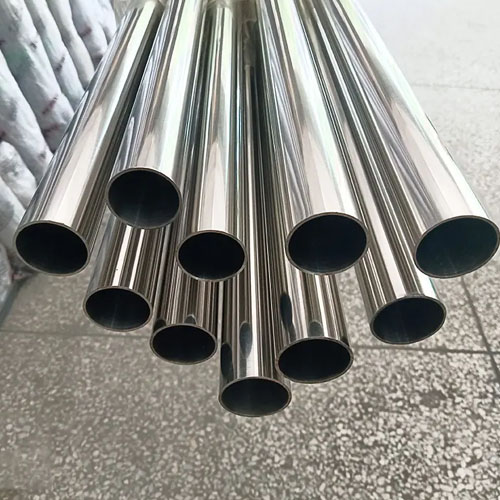

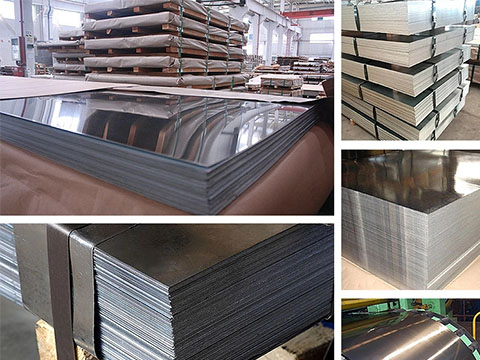

Wanzhi 316 stainless steel includes 316 stainless steel pipes, 316 stainless steel bars, 316 stainless steel plates, etc. The basic materials of 316 stainless steel are divided into cold rolling and hot rolling.

Thickness: Cold rolling: 0.1mm-6mm; hot rolling: 3.0mm-180mm

Width: 100mm-2000mm or as required

Length: According to customer requirements

Transportation: Container、Bulk Ship、Train Or as your request

Ensure product quality and transportation

316 stainless steel contains molybdenum, which has stronger corrosion resistance and high temperature resistance, and can be used for a long time in harsh environments.It is widely used in petrochemical and chemical industries, medical equipment, marine engineering and other fields.

316 Stainless Steel Specifications

| Product Name | 316 stainless steel |

| Thickness(mm) | Cold rolling: 0.1mm-6mm; hot rolling: 3.0mm-180mm |

| Width(mm) | 100mm-2000mm or as required |

| Length | According to customer requirements |

| Surface type | 2B, BA, No.1, No.4, HL, No.8, mirror, No.4, HL NSP, sandblasting, vibration |

| Density | 8.00g/cm³ |

| Package | Standard Seaworthy Package or as required |

316 Stainless Steel Chemical Composition

| Chemical composition | 316 Stainless Steel |

| C | ≤0.08% |

| Si | ≤1.00% |

| Mn | ≤2.00% |

| P | ≤0.045% |

| S | ≤0.030% |

| Ni | 11.00-14.00% |

| Cr | 16.00-18.00% |

| Mo | 1.80-2.50% |

316 Stainless Steel Performance

1. Corrosion Resistance

316 stainless steel has stronger corrosion resistance than 304 stainless steel. 316 stainless steel can resist the erosion of highly corrosive media, especially in high chloride environments, and can maintain stability for a long time.

2. Heat Resistance

316 stainless steel has good heat resistance and has good oxidation resistance when used at high temperatures.

3. Processing Performance

316 stainless steel has good processing performance and can be processed into products of various shapes and sizes.

4. Welding Performance

316 stainless steel has good welding performance and is suitable for a variety of welding methods.

5. Mechanical Properties

| Mechanical strength index | Value |

| Yield strength (0.2% deviation) | ≥205 MPa |

| Ultimate tensile strength | 515 MPa |

| Elongation | ≥40% |

| Hardness (Brinell hardness) | 70-90HRC |

FAQ about 316 Stainless Steel

What is the difference between 316 stainless steel and 316l stainless steel?

The biggest difference between 316 stainless steel and 316l stainless steel is the different chemical composition. The carbon content of 316l stainless steel is lower than that of 316 stainless steel, generally below 0.03%.Due to the low carbon content of 316l, the strength and hardness of 316l stainless steel are not as strong as 316 stainless steel, and the welding performance will be better, and the price of 316l stainless steel will be more expensive.

Which is better, 304 stainless steel or 316 stainless steel?

Which is better, 304 stainless steel or 316 stainless steel, mainly depends on the environment and budget of your project application.In general, the performance of 316 stainless steel is better than 304 stainless steel, but the price will also be more expensive.Specific reference: Which is better, 304 stainless steel or 316 stainless steel?

ASTM 316 Stainless Steel Equivalent?

| ASTM | GB | JIS | DIN |

| 316 | 0Cr17Ni12Mo2 | SUS316 | 1.4401 |

How to choose the stainless steel that suits you?

To choose the stainless steel that suits you, you need to understand it from five aspects: material, surface treatment method, thickness, usage scenario, price, etc.

First, you need to determine the material used.The corrosion resistance and strength of stainless steel of different materials are different.

In addition, there are many ways to treat the surface of stainless steel, such as polishing and sandblasting. Different surface treatment methods present different appearances and textures.

Finally, you need to consider the thickness, usage scenario, and price of stainless steel. The thicker the stainless steel, the higher the price. Different stainless steels are selected for different usage scenarios.