2B Finish Stainless Steel

Wanzhi Steel 2B Finished Stainless Steel includes a variety of materials, 201, 304, 316, 430, etc., with complete specifications and sizes, high surface quality and stable performance. If you have any needs, please contact us.

Thickness: 0.3mm – 4mm

Width: 1000mm, 1219mm (48 inches), 1250mm, 1500mm, 1800, 2000mm

Length: Cutting according to customer needs

Ensure product quality and transportation

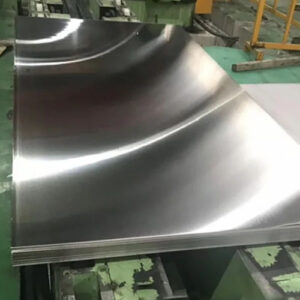

2B finish is a common finish for stainless steel. It is cold rolled, heat treated, pickled or descaled. The surface is smooth and flat. It has the characteristics of excellent corrosion resistance, easy cleaning and good processing performance.

Specification

| Product name | 2B Finish Stainless Steel |

| Thickness | 0.3mm – 4mm |

| Width | 1000mm, 1219mm (48 inches), 1250mm, 1500mm, 1800, 2000mm |

| Length | Cutting according to customer needs |

| Material | 304, 316L, 304L, 201, 410, 430, etc. |

| Technology | Hot Rolled / Cold Rolled |

| Standard | GB,JIS,EN,ASTM |

| Surface treatment | Frosting, brushing, etching, coating, passivation, sandblasting, etc. |

| Processing Services | Cutting, bending, stamping, rolling, rounding, deep drawing, etc. |

| MOQ | 5 tons |

| Packing | Standard export package or as per your requirements |

2B Finish Stainless Steel Application

- Construction: elevator panels, wall decoration, ceilings, curtain walls, door and window frames, handrails, railings, signs, etc.

- Chemical/food equipment: commonly used to make storage tanks, agitators, conveying pipes, reactors, conveyor belts/worktops for food production lines, etc.

- Catering industry: used to make stoves, hoods, sinks, worktops, cutlery, trays, food carts, etc.

- Medical and pharmaceutical industry: operating table tops, trays for medical equipment, sterilization containers, drug storage cabinets, bedside tables in wards, nursing tables, workbenches for laboratory equipment, etc.

- Other common applications: subway/high-speed rail car interior panels, luggage racks; valves, pump bodies, bearing housings, conveyor belt supports and other mechanical parts.

304 2B Stainless Steel vs 201 2B Stainless Steel

| Comparison items | 304 2B SS | 201 2B SS |

| Main ingredients | 18% Cr, 8-10% Ni (high nickel chromium) | 16-18% Cr, 3.5-5.5% Ni (manganese replaces part of nickel) |

| Corrosion resistance | Excellent corrosion resistance, acid and alkali resistance, suitable for outdoor/chemical industry | Weak corrosion resistance, easy to rust, only suitable for dry environment |

| Mechanical properties | Good ductility, easy deep stamping and welding | High strength, but poor toughness, slightly difficult to process |

| Price | Higher (30-50% more expensive than 201) | Low cost performance (high cost performance, but short life) |

| Typical uses | Food equipment, medical, coastal construction, high-end home appliances | Interior decoration, ordinary furniture, shelves, filing cabinets |

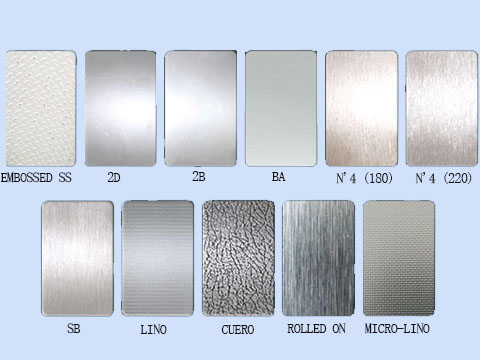

Comparison of Different Finishes of Stainless Steel

| Different finishes | Processing types | Appearance |

| 1D | Hot rolled, heat treated, pickled or descaled | Rough and matte |

| 2E | Cold rolled with oxide scale, heat treated, descaled | Rough and matte |

| 2D | Cold rolled, heat treated, pickled or descaled | Uniform surface, matte |

| 2B | Cold rolled, heat treated, pickled or descaled, bright finished (matte finish) | Smoother and straighter than 2D surface |

| BA | Cold rolled, bright annealed (mirror finish) | Smooth, shiny, reflective |

| 3# | Brushed or matte polished on one or both sides | No directional texture, no reflective |

| 4# | Universal polished on one or both sides | No directional texture, reflective |

| 6# | Matte satin polished on one or both sides, one side can be ground | Matt, no directional texture |

| 7# | High gloss surface processing | Smooth, high reflectiveness |

| 8# | Mirror processing | No directional texture, high reflectiveness, clear image |

| TR | Cold hardening treatment: 1/4H, 1/2H, 3/4H, H | Varies according to the material and the amount of cold work |

| HL | Cold rolling, pickling, flattening, grinding | Continuous grinding pattern, also known as hairline plate |

Corresponding names of finishes in different countries

| GB | ASTM | JIS | ISO | EN |

| 1U | 1U | 2U | ||

| 1C | 1C | 2C | ||

| 1E | 1E | 2E | ||

| 1D | No.1 | No.1 | 1D | 2D |

| 2E | 2E | 2E | ||

| 2D | No.2D | No.2D | 2D | 2D |

| 2B | No.2B | No.2B | 2B | 2B |

| BA | BA | BA | 2R | 2R |

| 3# | No.3 | No.3 | 2G | 2G |

| 4# | No.4 | No.4 | 2G | 2G |

| 6# | No.6 | 240# | 2J | 2J |

| 7# | No.7 | 320# | 2K | 2K |

| 8# | No.8 | 400# | 2P | 2P |

| TR | TR | 2H | 2H | |

| HL | HL |

Our certificates

Why Choose Us?

- With 17+ production experience and 14+ export experience, and passed ISO 9001, ISO 14001, honest supplier and other certifications.

- A wide range of product types, including but not limited to: coils, plates, strips, pipes, bars, wires, stainless steel water tanks, etc.

- With a strict testing process, both raw materials and finished products are strictly tested, including composition, specifications, performance, etc.

Wanzhi Steel is a professional stainless steel product supplier in China, with customers in more than 120 countries, and competitive prices. If you have any needs, please feel free to contact us.